9 ENGLISH

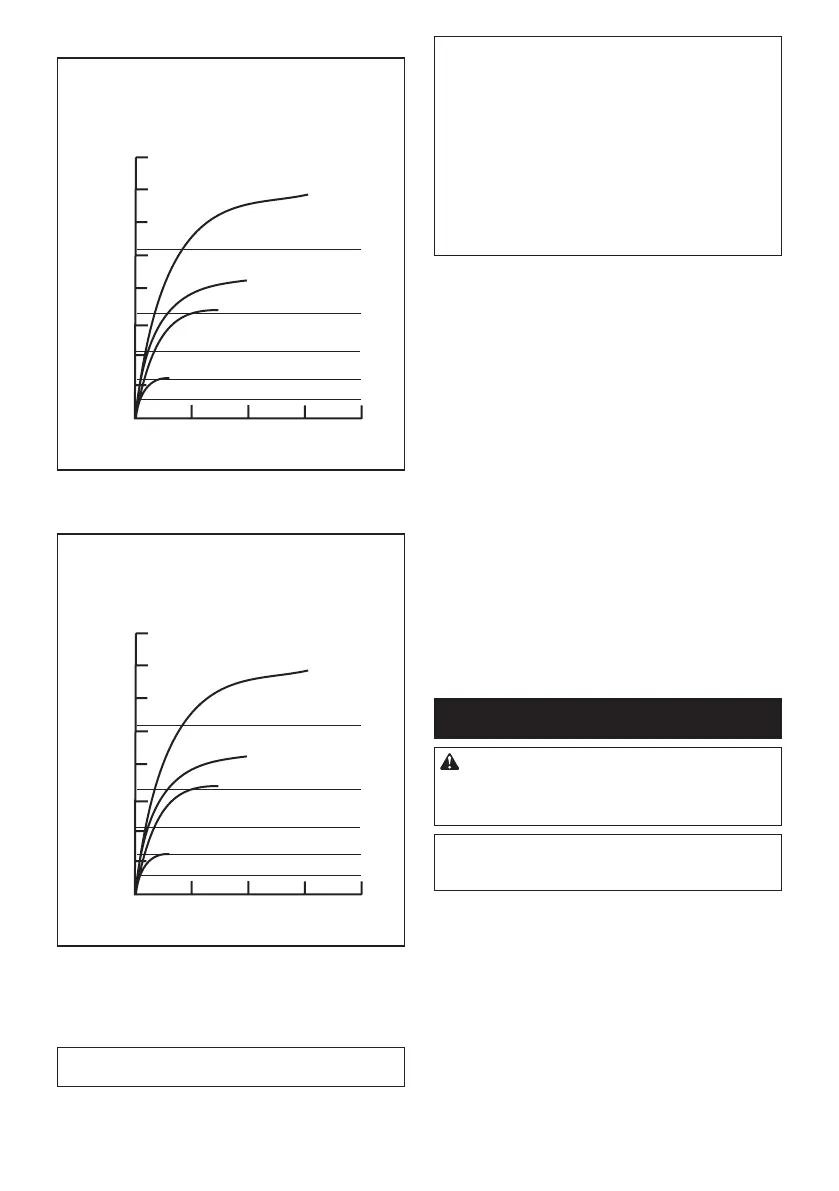

Proper fastening torque for standard bolt

2

1

N•m

(kgf•cm)

160

(1632)

140

(1428)

120

(1224)

100

(1020)

80

(816)

60

(612)

40

(408)

20

(204)

0

M14

M12

(M14)

(M16)

(M12)

(M10)

(M8)

M10

M8

2.0 3.04.01.0

1.Fasteningtime(second)2.Fasteningtorque

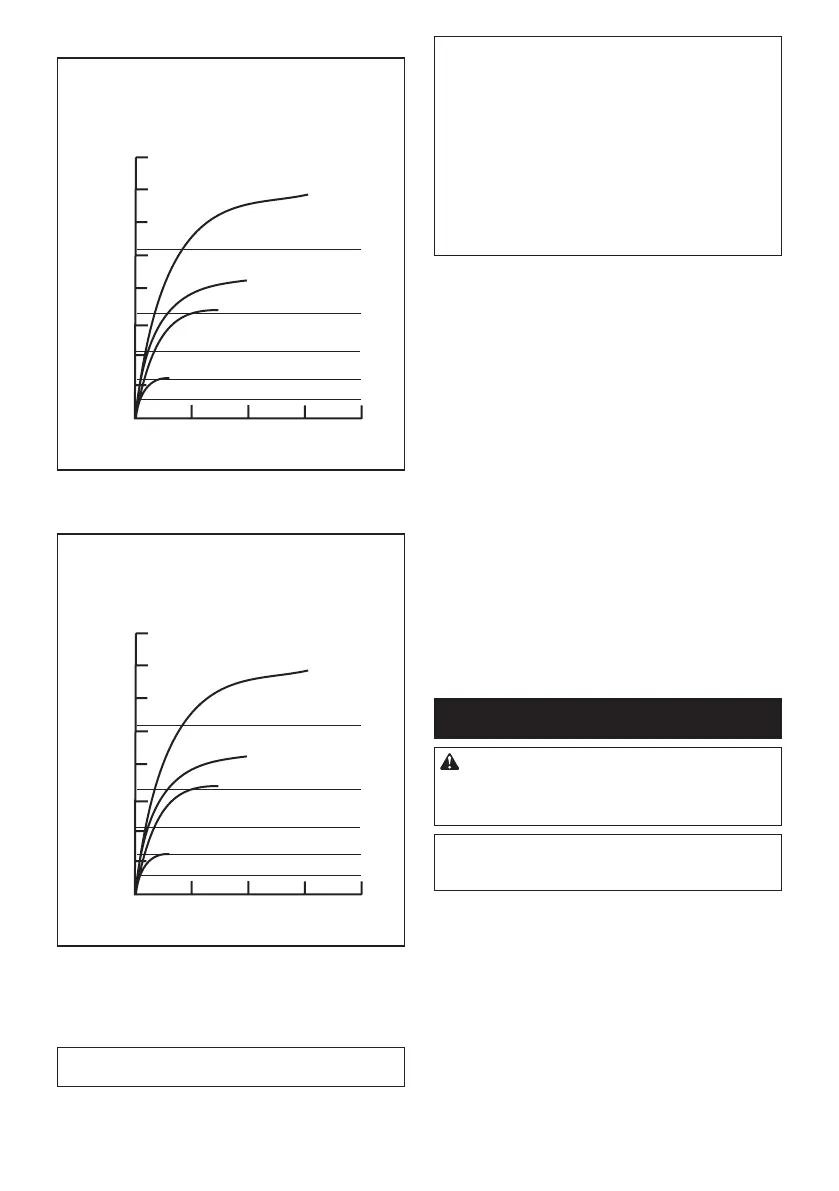

Proper fastening torque for high tensile bolt

2

1

N•m

(kgf•cm)

160

(1632)

140

(1428)

120

(1224)

100

(1020)

80

(816)

60

(612)

40

(408)

20

(204)

0

M14

M12

(M14)

(M16)

(M12)

(M10)

(M8)

M10

M8

2.0 3.04.01.0

1.Fasteningtime(second)2.Fasteningtorque

Holdthetoolrmlyandplacethepointofthedriverbit

inthescrewhead.Applyforwardpressuretothetoolto

the extent that the bit will not slip off the screw and turn

the tool on to start operation.

NOTICE: If you use a spare battery to continue

the operation, rest the tool at least 15 min.

NOTE: Use the proper bit for the head of the screw/

boltthatyouwishtouse.

NOTE:WhenfasteningM8orsmallerscrew,carefully

adjustpressureontheswitchtriggersothatthescrew

is not damaged.

NOTE: Hold the tool pointed straight at the screw.

NOTE:Iftheimpactforceistoostrongoryoutighten

thescrewforatimelongerthanshowninthegures,

thescreworthepointofthedriverbitmaybeover-

stressed,stripped,damaged,etc.Beforestartingyour

job,alwaysperformatestoperationtodeterminethe

properfasteningtimeforyourscrew.

Thefasteningtorqueisaffectedbyawidevarietyof

factorsincludingthefollowing.Afterfastening,always

checkthetorquewithatorquewrench.

1. Whenthebatterycartridgeisdischargedalmost

completely,voltagewilldropandthefastening

torquewillbereduced.

2. Driver bit or socket bit

Failure to use the correct size driver bit or socket

bitwillcauseareductioninthefasteningtorque.

3. Bolt

• Eventhoughthetorquecoefcientandthe

class of bolt are the same, the proper fasten-

ingtorquewilldifferaccordingtothediame-

ter of bolt.

• Even though the diameters of bolts are the

same,theproperfasteningtorquewilldiffer

accordingtothetorquecoefcient,theclass

of bolt and the bolt length.

4. The manner of holding the tool or the material

of driving position to be fastened will affect the

torque.

5. Operating the tool at low speed will cause a reduc-

tioninthefasteningtorque.

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY, repairs,

carbonbrushinspectionandreplacement,anyother

maintenanceoradjustmentshouldbeperformedby

MakitaAuthorizedorFactoryServiceCenters,always

using Makita replacement parts.

Loading...

Loading...