10 ENGLISH

Removing or installing cut-o wheel

CAUTION: Be sure to tighten the hex socket

bolt securely.Insucienttighteningmayresultin

severeinjury.Whentighteningthehexsocketbolt,

use the hex wrench provided with the tool to assure

proper tightening.

CAUTION: Always use only the proper inner

and outer anges which are provided with the

tool.

CAUTION: Always lower the safety guard

after replacing the wheel.

CAUTION: Wear gloves when handling

wheels.

►Fig.9: 1.Innerange2. Ring 3. O-ring 4. Bonded

reinforcedcut-owheel5.Outerange

6. Washer 7.Hexsocketbolt

Raisethesafetyguard.Turnthehexsocketboltcoun-

terclockwise using a hex wrench while holding down the

shaftlock.Thenremovethehexsocketbolt,washer,

outerangeandwheel.

►Fig.10: 1. Shaft lock 2.Hexsocketbolt

To install the wheel, follow the removal procedures in

reverse.Makesuretottheholeofcut-owheeltothe

ring and return the safety guard.

Hex wrench storage

►Fig.11: 1. Hex wrench

When not in use, store the hex wrench as shown in the

guretokeepitfrombeinglost.

OPERATION

CAUTION: Proper handle pressure during

cutting and maximum cutting eciency can

be determined by the amount of sparks that is

produced while cutting. Do not force the cut

by applying excessive pressure on the handle.

Reducedcuttingeciency,prematurewheelwear,as

wellas,possibledamagetothetool,cut-owheelor

workpiece may result.

Holdthehandlermly.Switchonthetoolandwaituntil

thecut-owheelattainsfullspeedbeforelowering

gentlyintothecut.Whenthecut-owheelcontacts

theworkpiece,graduallybeardownonthehandleto

performthecut.Whenthecutiscompleted,switcho

the tool and wait until the cut-o wheel has come to

a complete stop beforereturningthehandletothefully

elevated position.

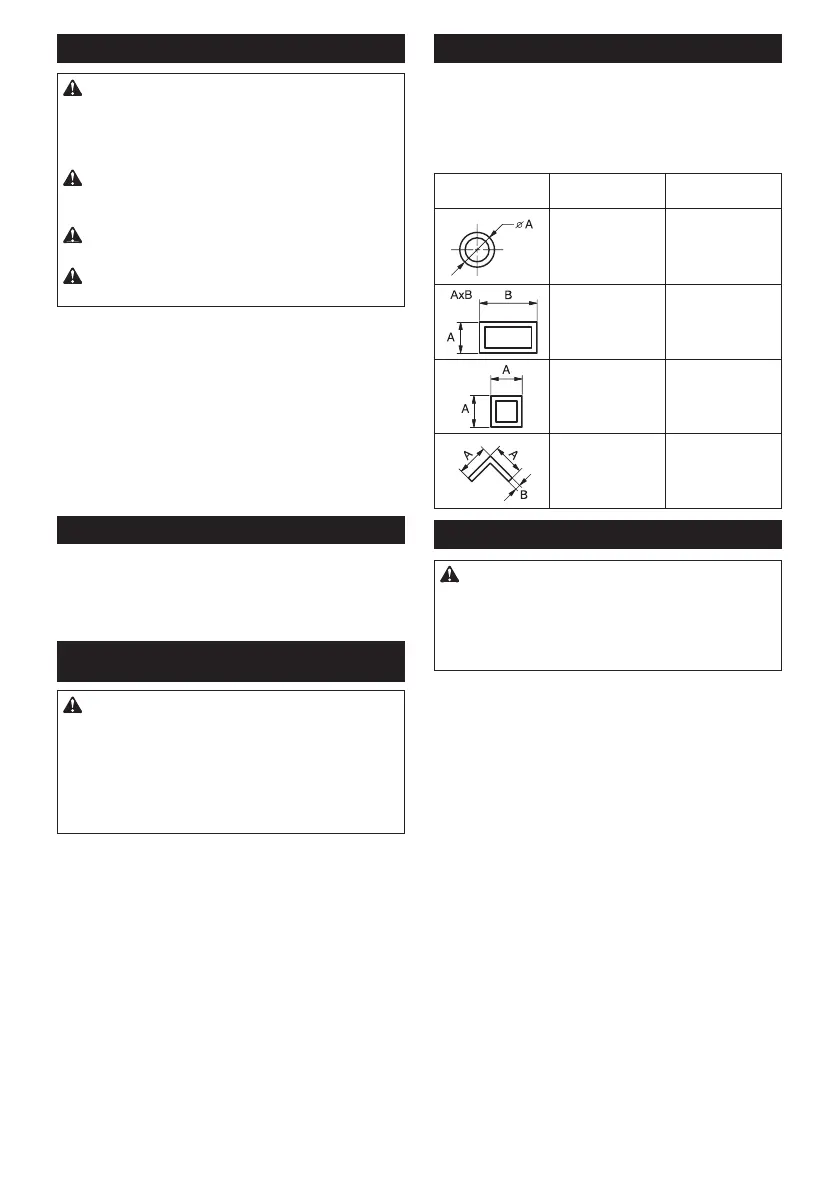

Cutting capacity

Maximum cutting capacity varies depending on the

cutting angle and workpiece shape.

Max. cutting capacity with a brand-new cut-o

wheel

Cutting angle /

Workpiece shape

90° 45°

127 mm

(5")

127 mm

(5")

102 x 194 mm

(4" x 7-5/8")

70 x 233 mm

(2-3/4" x 9-1/8")

115 x 103 mm

(4-1/2" x 4-1/16")

119 x 119 mm

(4-11/16" x

4-11/16")

106 x 106 mm

(4-3/16" x 4-3/16")

137 x 137 x 10 mm

(5-3/8" x 5-3/8"

x 3/8")

100 x 100 x 10 mm

(4" x 4" x 3/8")

Securing workpiece

CAUTION: Always place the thread holder on

the shaft threads when securing the workpiece.

Failuretodosomayresultininsucientsecuringof

theworkpiece.Thiscouldcausetheworkpiecetobe

ejectedorcauseadangerousbreakageofthecut-o

wheel.

Whilethethreadholderislifted,theviseplatecanbe

moved in and out quickly. To grip a workpiece, push the

handle until the vise plate contacts the workpiece then

return the thread holder. Turn the handle clockwise until

the workpiece is securely retained.

►Fig.12: 1. Handle 2. Thread holder 3. Vise plate

Whenthecut-owheelhasworndownconsiderably,

placeaspacerblockbehindtheworkpieceasshown

inthegure.Youcanmoreecientlyutilizetheworn

wheelbyusingthemidpointontheperipheryofthe

wheeltocuttheworkpiece.Useasturdyandnon-am-

mablematerialforaspacerblock.

►Fig.13: 1.Spacerblock

When cutting workpieces over 85 mm (3-3/8") wide at

an angle, attach a straight piece of wood (spacer) over

190 mm (7-1/2") long x 45 mm (1-3/4") wide to the guide

plateasshowninthegure.Attachthisspacerwith

screws through the holes in the guide plate. Make sure

thatthecut-owheeldoesnotcontactthespacerwhen

the tool head is depressed.

►Fig.14: 1. Guide plate 2.Spacerblockover

190 mm (7-1/2") long x 45 mm (1-3/4") wide

3. Workpiece over 85 mm (3-3/8") wide

4. Vise plate

►Fig.15

Loading...

Loading...