Maintenance and care

40

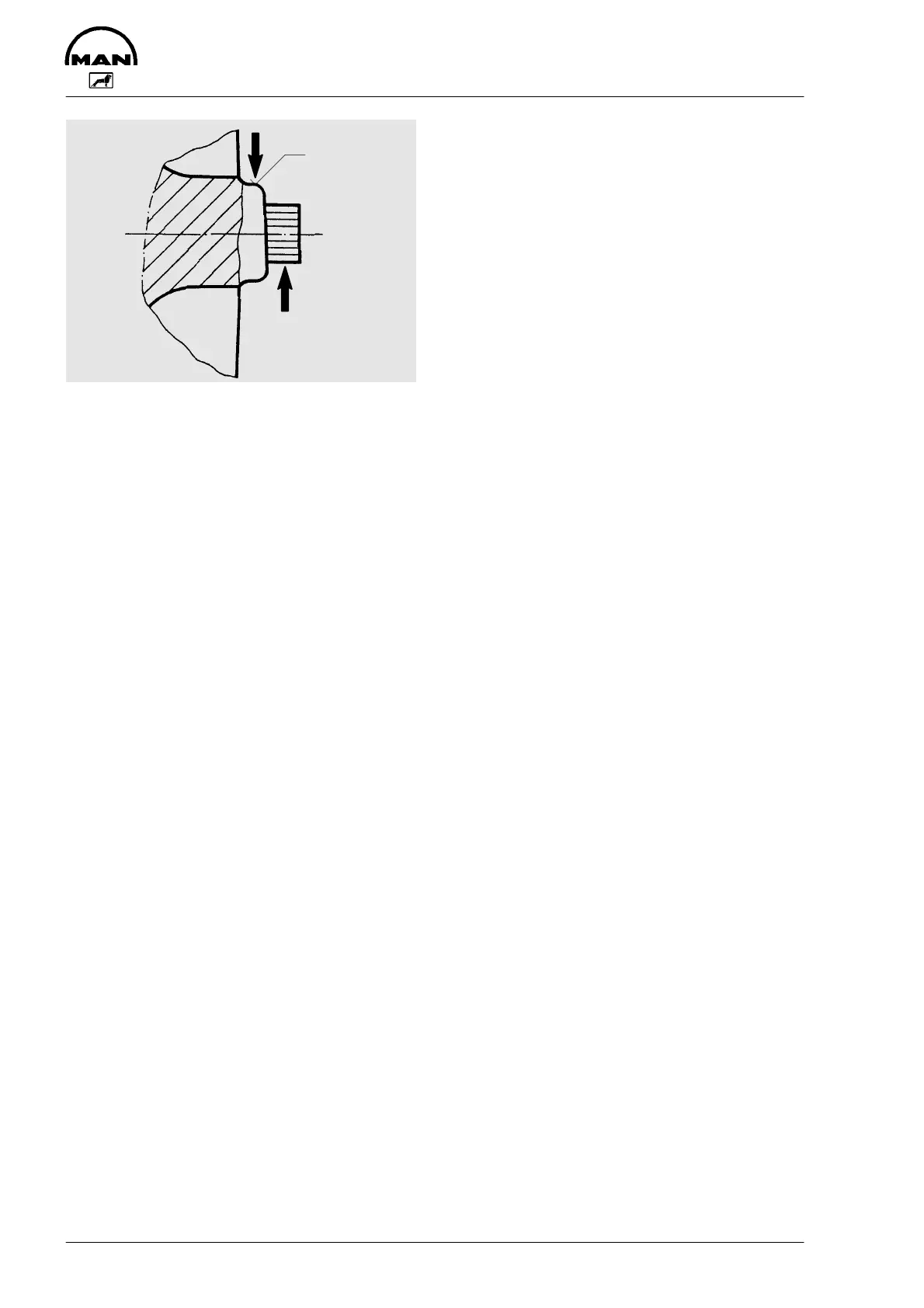

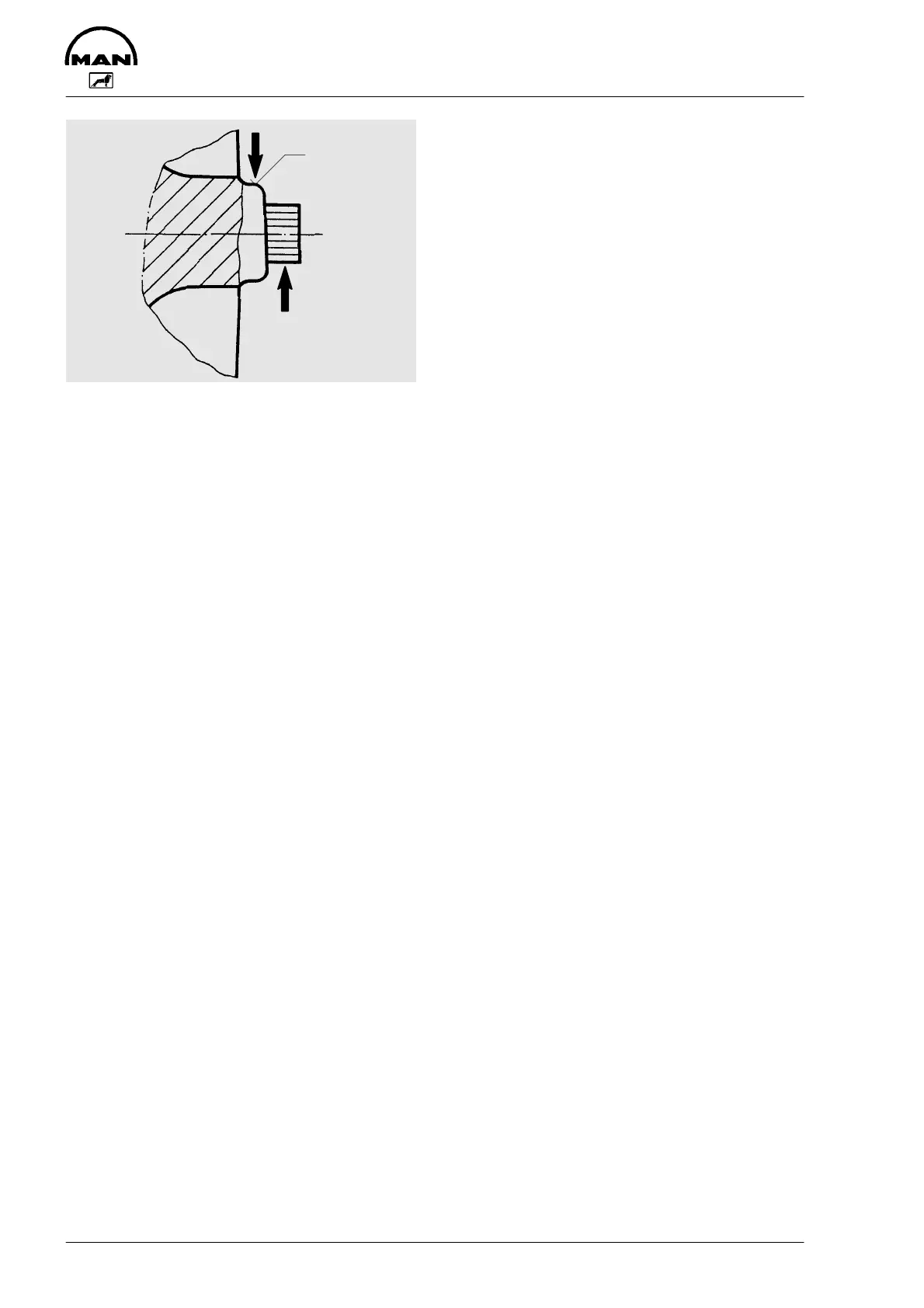

B

A

A = Point of support for dial gauge tip

B = Measuring capacity

Axial and radial clearances

KKK

model

axial

(mm)

radial

(mm)

D 2866

TE/LE/LXE

with liquid-

cooled exhaust

manifold

K 36 0,16 0,58

D 2866

TE/LE/LXE

with uncooled

exhaust manifold

4LGZ 0,20 0,65

If excessive clearances are found, the

turbocharger should be replaced.

Intercooler

Maintenance

(by authorized specialist personnel)

In order to maintain the heat transfer effi-

ciency of the intercooler, it is necessary to

clean it at regular intervals which depend

on the quality of the coolant used.

For this purpose, dismantle the inter-

cooler. In almost all cases, it will suffice to

clean the individual parts in a hot alkaline

solution, e.g. a 3 to 5% P3-FD solution.

Should hard and firmly adhering scale de-

posits continue to exist a second treat-

ment should be made with a descaling

agent which will not corrode the cooler

core.

Use new gaskets when assembling the

cooler.

Be sure to clean the sealing surfaces

carefully before installing the gaskets.

Observe the specified pressure when

making the hydraulic test.

Test gauge pres-

sure

water side 4 bar

charge air

side

3 bar

Loading...

Loading...