Checking and setting

51

Re-using old cylinder head bolts

Checking

Before re-using old cylinder head bolts

check them as follows:

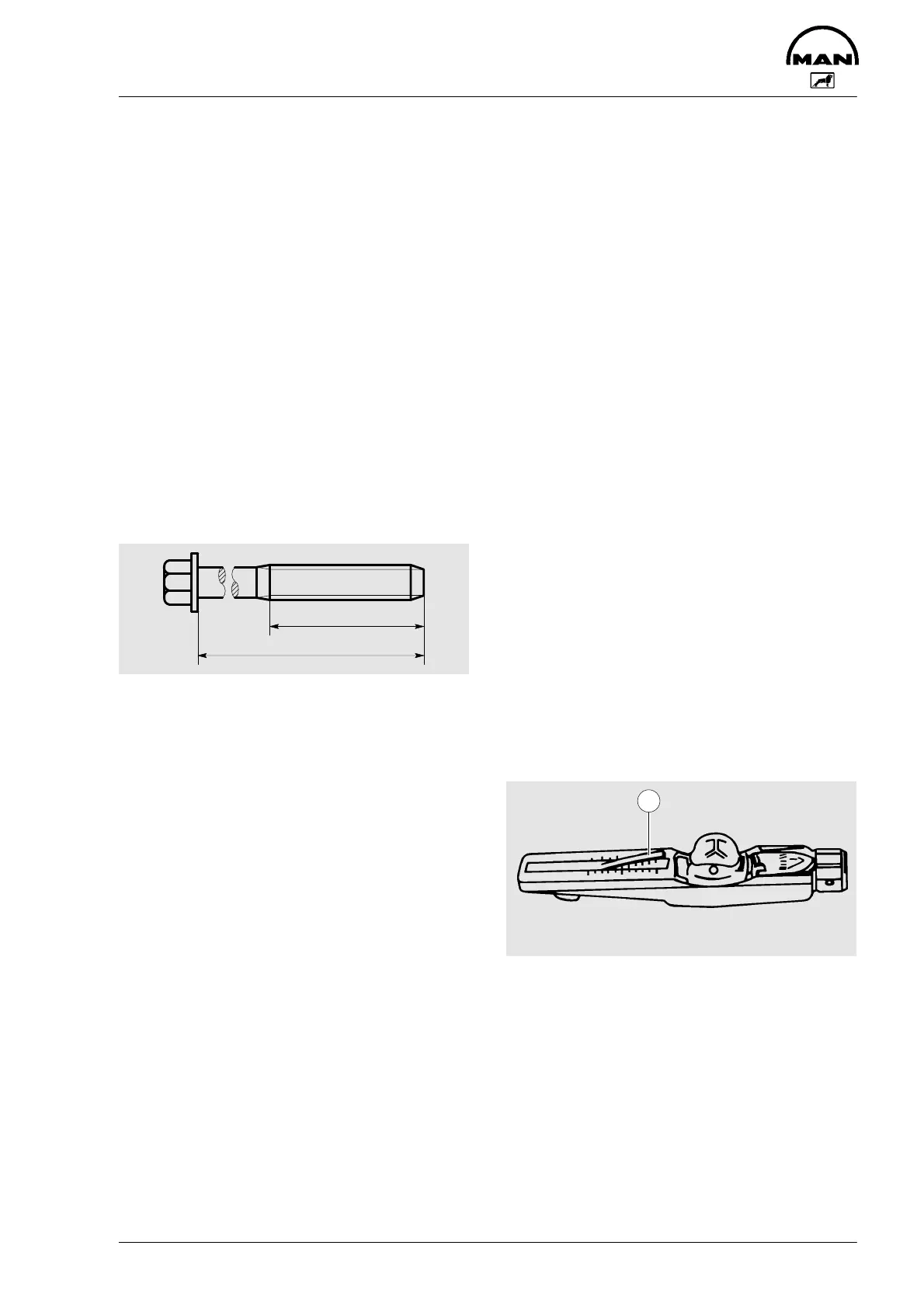

Length

During tightening the bolts are intention-

ally stressed beyond the yield point and

therefore subjected to some permanent

elongation each time they are tightened.

The shank lengths “L” of new bolts are

109, 144 and 168 mm.

Permissible maximum lengths are 111,

146 and 170 mm respectively

.

90

+3

L

L = Shank length

Surface

The surface of the bolts must be in satis-

factory condition, i.e. the phosphate coat-

ing must be intact and there must be no

rust.

Rusted or damaged bolts or bolts elon-

gated beyond the maximum permissible

length must immediately be made unus-

able – e.g. by destroying the threads with

a hammer – and scrapped.

V-belts

The tension of the V-belts should be

checked after every 200 hours of oper-

ation.

Change the V-belts if necessary

If, in the case of a multiple belt drive, wear

or differing tensions are found, always re-

place the complete set of belts.

Checking condition

Check V-belts for cracks, oil, overheating

and wear.

Change demaged V-belts.

Testing by hand

A more precise check of the V-belt tension

is possible only by using a V-belt tension

tester.

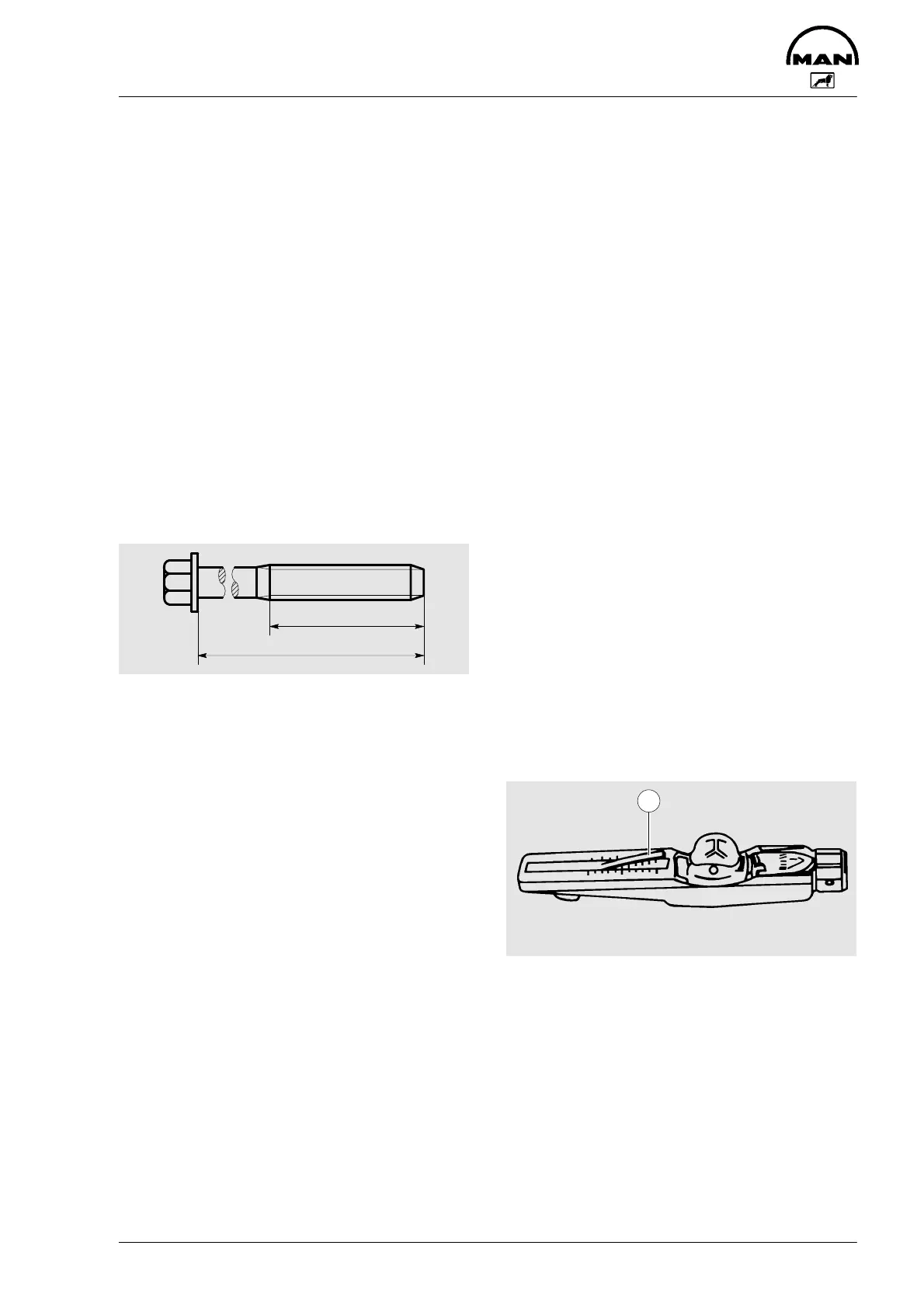

Check with V-belt tension tester

1

Measuring tension

D Lower indicator arm À into the scale

D Apply tester to belt at a point midway

between two pulleys so that edge of

contact surface Á is flush with the

V-belt

Loading...

Loading...