HYDRAULIC SYSTEM 18000 SERIVCE/MAINTENANCE MANUAL

2-36 Published 12-05-17, Control # 035-23

HYDRAULIC SYSTEM ADJUSTMENT

PROCEDURES

High Pressure Adjustment

The following adjustment is only required when a system

fails the High Pressure Test described in this section.

Unless otherwise specified, see Figure 2-28

for the following

procedure.

1. Scroll to system component screen for corresponding

function.

2. Disconnect electrical (DIN) connector from

corresponding brake solenoid valve (see Figure 2-16

).

3. With engine running at low idle, slowly move desired

control handle in either direction.

4. Do not demand any more than 20% handle command.

5. Pressure on screen should indicate pressure specified

in Table 2-10

.

6. If proper pressure is not indicated, adjust the

corresponding multi-function valve:

a. Remove protective cap (3) from multi-function valve

(1 or 2). See Table 2-10

and Figure 2-21 for pump

port identification.

b. Loosen lock nut (4).

DO NOT tamper with bypass hex (6). See pump

manufacturer’s instructions.

c. Using an internal hex wrench, adjust multi-function

valve adjusting screw (5).

- Turn IN to INCREASE pressure.

- Turn OUT to DECREASE pressure.

7. Repeat steps until specified pressure is indicated.

8. Hold adjusting screw (5) in position and securely tighten

lock nut (4).

9. Install protective cap (3).

10. Reconnect electrical (DIN) connector to corresponding

brake solenoid valve (see Figure 2-16

).

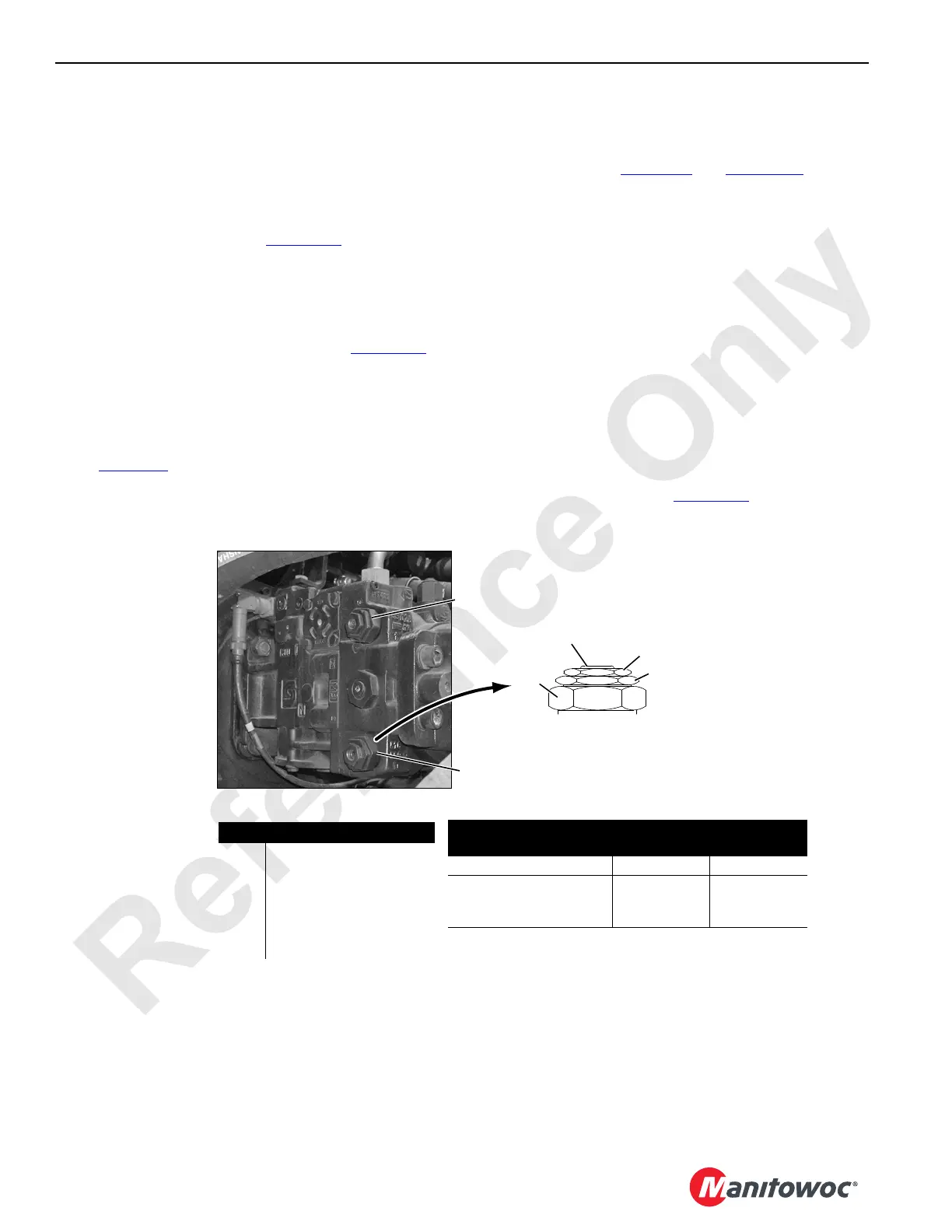

P1537a

Item Description

1 Port A Multi-Function Valve

2 Port B Multi-Function Valve

3Protective Cap

4 Lock Nut

5 Adjusting Screw

6Bypass Hex

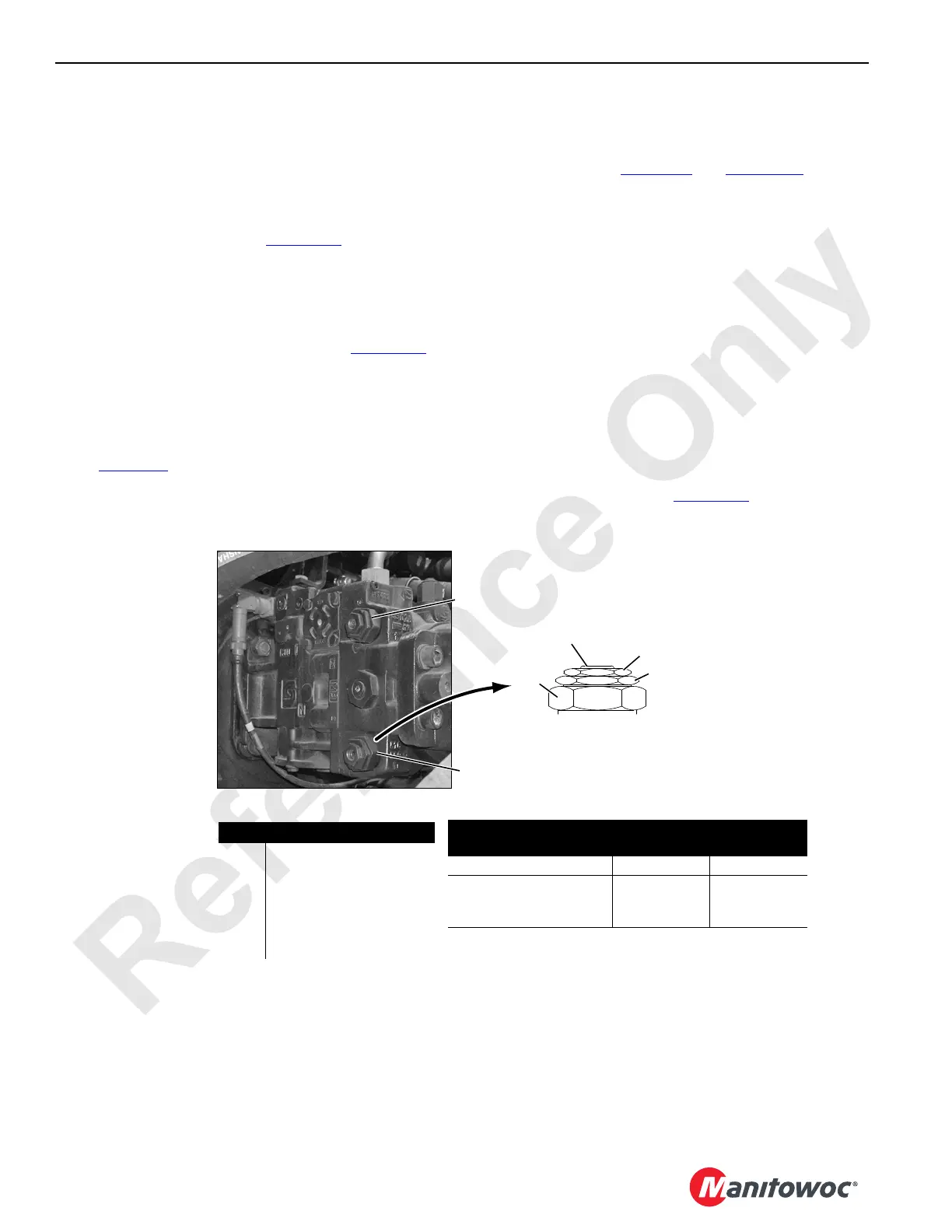

Wrench Size

Pump Size

Lock Nut

Hex Size

Internal

Hex Size

Series 042 -100 Units 19 mm 5 mm

Series 130 Units

13 mm

or

24 mm

4 mm

or

8 mm

Multi-Function Valve

A1161

FIGURE 2-28

1

4

6

1

3 (5 under)

2

2

Typical Pump Installation

Loading...

Loading...