Do you have a question about the Manitowoc QY0694N and is the answer not in the manual?

Lists all models covered by the manual and explains how to read model numbers.

Diagrams illustrating where to find model and serial number decals on the machine.

Details the terms, parts, labor, exclusions, and authorized service for the warranty.

Provides physical dimensions and height specifications for various ice machine models.

Details the dimensions for different ice storage bin models (S170, S400, S570, S320, S420).

Covers general electrical requirements, voltage, fuse/breaker needs, and ampacity.

Guidelines for water supply, inlet lines, drain connections, and cooling tower applications.

Instructions for installing remote condensers and refrigerant line sets.

A comprehensive checklist to ensure proper installation of the ice machine.

Procedures for routine checks including water level and ice thickness adjustment.

Step-by-step instructions for cleaning air-cooled and water-cooled condensers.

Procedures for cleaning and sanitizing the ice machine's interior surfaces.

Detailed steps for cleaning the ice machine to remove mineral deposits.

Detailed steps for sanitizing the ice machine to remove algae or slime.

Instructions for safely removing parts for thorough cleaning and sanitizing.

Procedure for removing and cleaning the water dump valve.

Procedure for removing and cleaning the water pump.

Procedure for removing and cleaning the ice thickness probe.

Procedure for removing and cleaning the water level probe.

Procedure for removing and cleaning the water inlet valve.

Procedure for removing and cleaning the water distribution tube.

Procedure for removing and cleaning the water curtain.

Information on water treatment systems and filter replacement procedures.

Procedures for preparing the ice machine for extended storage or winter.

Operation sequence for self-contained models, including startup, freeze, harvest, and shut-off.

Operation sequence for remote models, covering startup, freeze, harvest, and shut-off.

Describes the initial startup and restart sequence for the water system.

Explains the water flow and valve operation during the freeze cycle.

Details the safety feature that limits water inlet valve operation time.

Describes the water flow and valve operation during the harvest cycle.

Explains the automatic shut-off condition for the water system.

Charts detailing which parts are energized during each ice making sequence step.

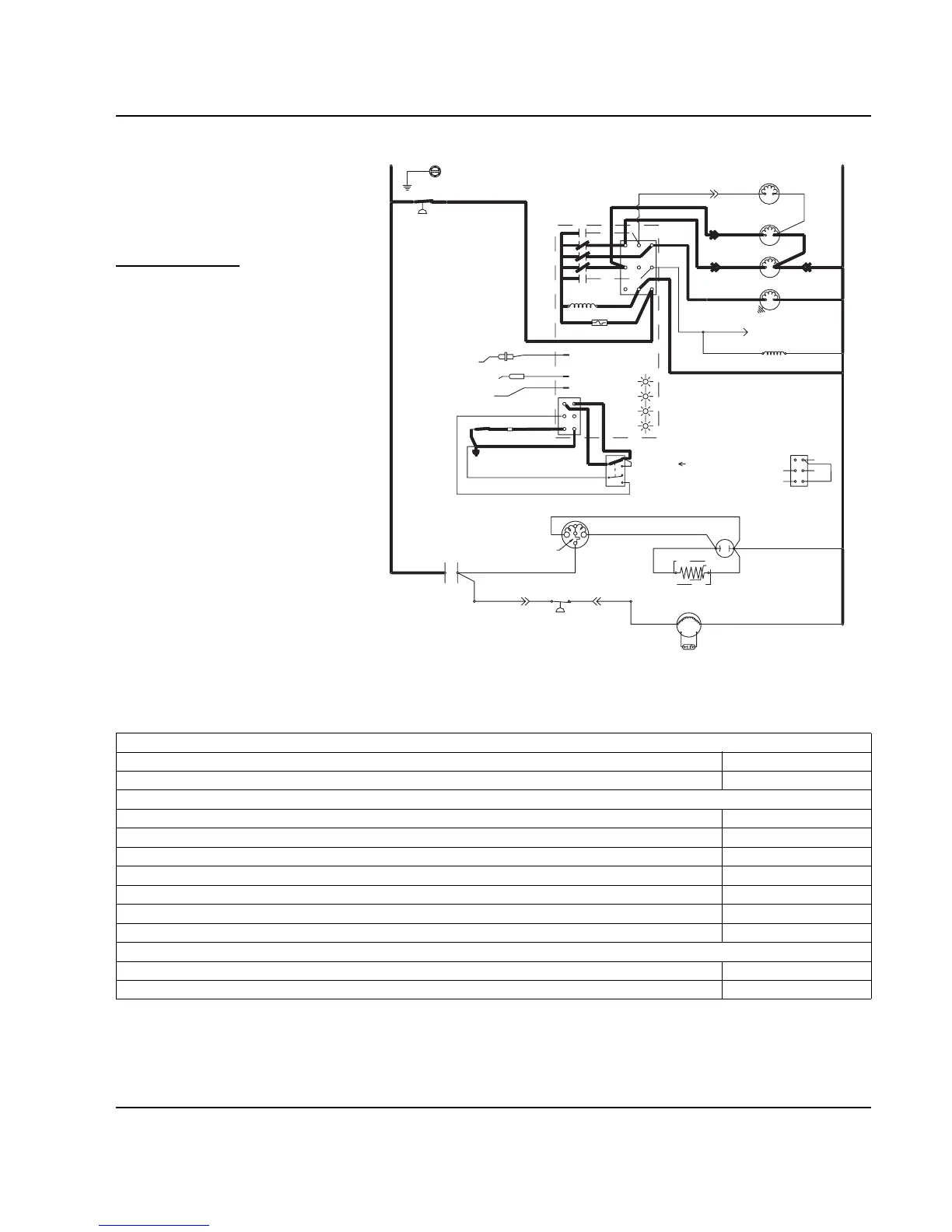

An introduction to wiring diagrams with a legend for symbols used.

Technical specifications and diagnostic procedures for key electrical components.

Explanation of PTCR function and diagnostic steps for compressor starting issues.

Explains how the ice thickness probe functions and its role in harvest initiation.

Explains the water level probe and its control circuitry for freeze and harvest cycles.

Step-by-step troubleshooting guide for an ice machine that fails to start.

Overview of the refrigeration cycle for self-contained and remote models.

General guidance and examples for analyzing refrigeration system malfunctions.

Key questions to ask before starting service or diagnostics.

Procedure to check ice production based on operating conditions and actual output.

Checklist for installation and visual inspection to identify potential problems.

Checklist to identify and eliminate water system issues before component replacement.

Analysis of evaporator ice formation patterns to aid in diagnostics.

Explanation of built-in safety limit controls and their operation.

Explanation of how safety limits protect the machine from external failures.

Troubleshooting guide for Safety Limit #1 (freeze time exceeding limits).

Troubleshooting guide for Safety Limit #2 (harvest time exceeding limits).

Procedure for analyzing discharge pressure during the freeze or harvest cycle.

Procedure for analyzing suction pressure drop throughout the freeze cycle.

Procedure to compare evaporator inlet and outlet temperatures for diagnosis.

Procedure to check harvest valve temperature for proper operation.

Procedure for analyzing discharge line temperature to diagnose issues.

Guide on using operational analysis tables to diagnose refrigeration problems.

Tables correlating operational findings with specific refrigeration problems.

Explanation of the Harvest Pressure Regulating system for remote models.

Diagnostic steps for the HPR system, including pressure and temperature checks.

Operation and diagnosis of the Headmaster control valve in remote systems.

Procedure to verify if the ice machine has a low refrigerant charge.

Comparison of fan cycle control and Headmaster operation for condensers.

Specifications and diagnostic checks for Fan Cycle Control and HPCO.

Charts providing operational data and refrigerant pressures for various models.

Procedures for recovering, evacuating, and recharging refrigerant safely.

Step-by-step guide for charging refrigerant into self-contained ice machines.

Procedures for refrigerant recovery, evacuation, and connections for remote models.

Step-by-step guide for charging refrigerant into remote ice machines.

Basic requirements for restoring contaminated refrigeration systems to reliable service.

Steps for cleaning systems with mild contamination issues.

Steps for cleaning systems with severe contamination or burnout.

Procedure to replace specific components without discharging refrigerant.

Information on filter-driers and recommended O.E.M. field replacement parts.

Table listing refrigerant charge amounts for various ice machine models.

Definitions for terms like Recover, Recycle, Reclaim, and New Product Specifications.

Manitowoc's policy regarding the proper handling and reuse of refrigerants.

Frequently asked questions regarding HFC refrigerants, POE oils, and leak detection.