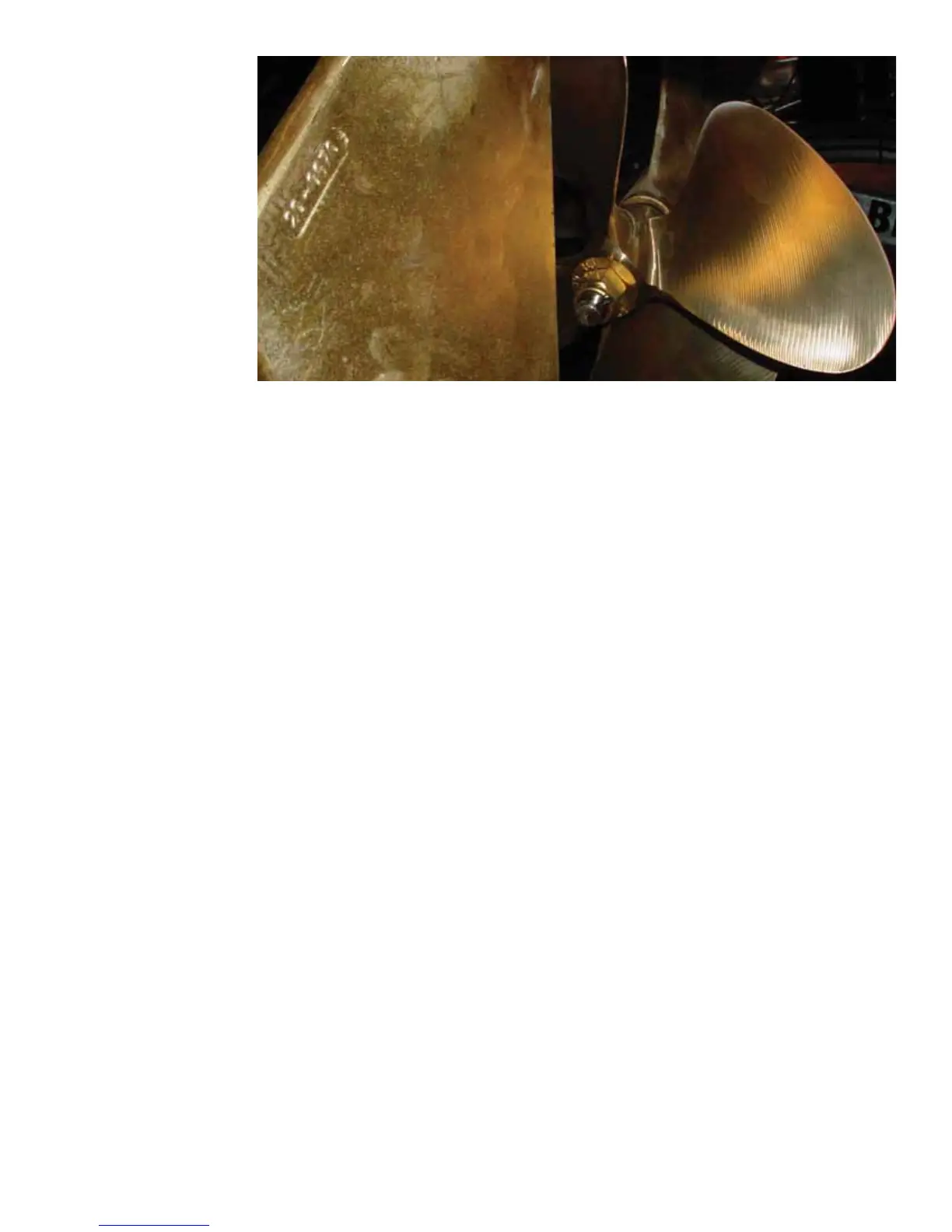

Propellerdamageiscausedbystrikingsolidobjects.Ifthepropel-

ler is not rotating at the time it strikes a solid object, the damage is

usuallyconnedtojustonebladeandmaybediculttosee.Ifthepro-

pellerisrotatingwhenitstrikesanobject,usuallytheresultingdamage

caneasilybeseenonallblades.

Checking/Repairing Propellers

Step 1: Ensure the engine is OFF and the emergency safety stop

switch is disconnected.

Step 2: Clamp a small rule scale to the shaft strut, parallel to the shaft

sothattheendofthescaleis3/32-inchesfromtheleading

edge of a propeller blade.

Step 3: Rotate the propeller slowly.Thereshould beno more than

3/32-inch variance between the blades. If the propeller is

damaged, see an authorized MasterCraft dealer.

Propeller

Maintenance

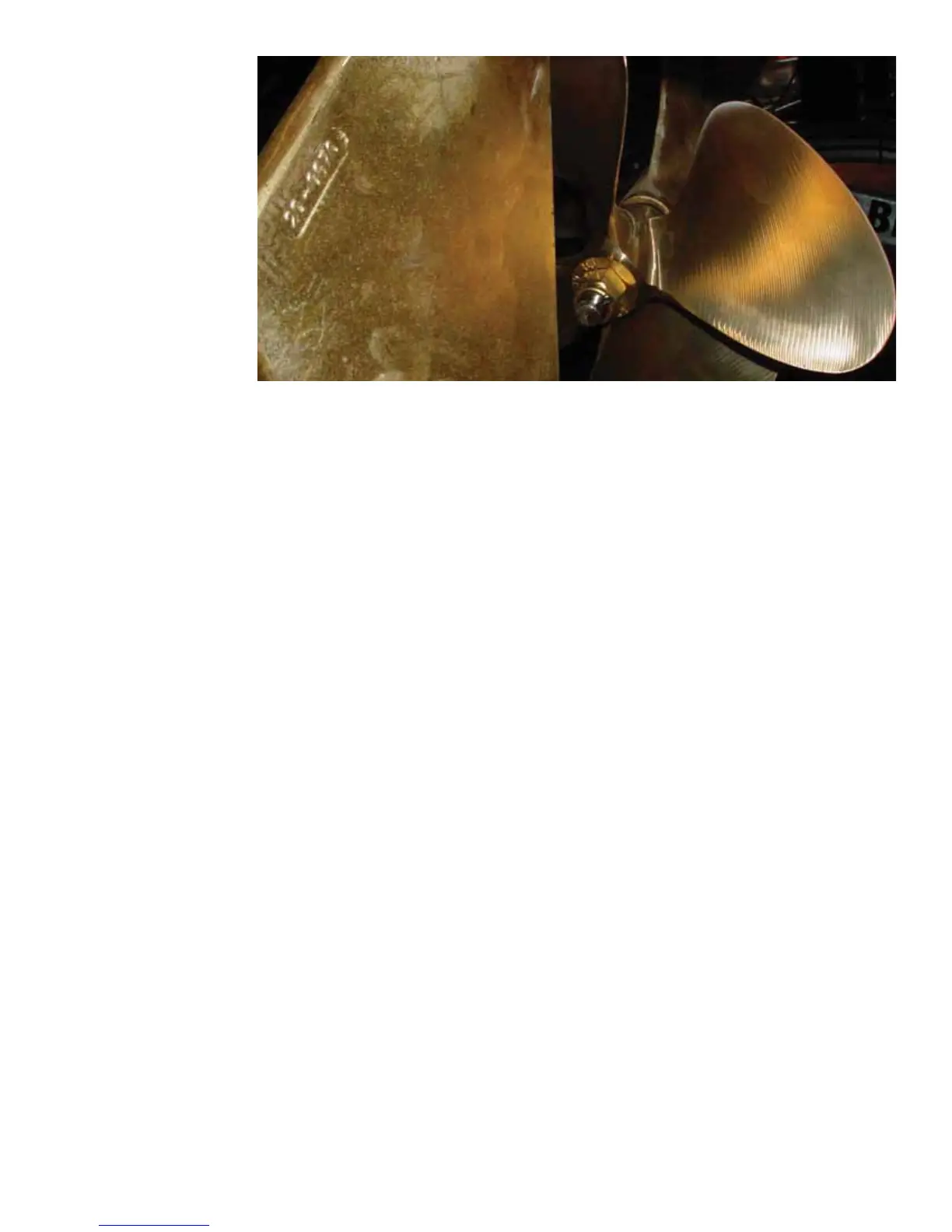

Changing Propellers

Step 1: EnsuretheengineisOFFandtheenginesafetystarting

switch is disconnected.

Step 2: Removeanddiscardthecotterpin.

Step 3: Removethepropellernut.

Step 4: Tap the center hub of the propeller with a rubber mallet

toreleasethepropeller.Inspecttheshaftandpropeller

splines for damage.

Step 5: Thoroughly clean and apply a light coat ofwaterproof

marine multi-purpose grease to the splined area of the

shaft and propeller.

Step 6: Alignthesplinesandcarefullyinstallthepropelleronto

the shaft. DO NOT FORCE THE PROPELLER INTO

PLACE.

Step 7: Installthepropellernutandtorqueto50-ft-lbs.

Step 8: Install a new cotter pinand bend the ends around the

shaft to lock the propeller on the shaft.

MasterCraft 2012 Owners Manual • Care and Maintenance • Page 4-23

Loading...

Loading...