4.01

TI013G0008

Transportation and handling -

Installation

The entire area used when

handling the machine, including

the area for parking the transport

used and for installing the

machine, must be identifi ed and inspected

in advance to identify any possible

“DANGEROUS AREAS”.

Be very careful when handling, lifting and

transporting the machine not to damage it

and not to damage things or cause injuries

to persons.

To that end:

Verify fi rst the

total weight of the

machine and use

a forklift truck

or an adequa-

te lifting means.

Specifi c picto-

grams indicate

the points suitable for lifting.

The center of gravity is close to the

motor axis. Before lifting, verify (by slightly

lifting the group from ground) that the lifting

points are correct and that it is not about to

overturn as this could be dangerous.

When lifting, be careful not to damage

the base of the machine and the soundproof

case.

During transportation, fi x the machine

accurately to the means used, blocking it

both longitudinally and on the side.

It is recommended to protect the machine

with adequate packaging to protect it from

environmental factors.

To unpack the machine, remove the guards

and place it on the fl oor by means of a

forklift truck to remove the pallet.

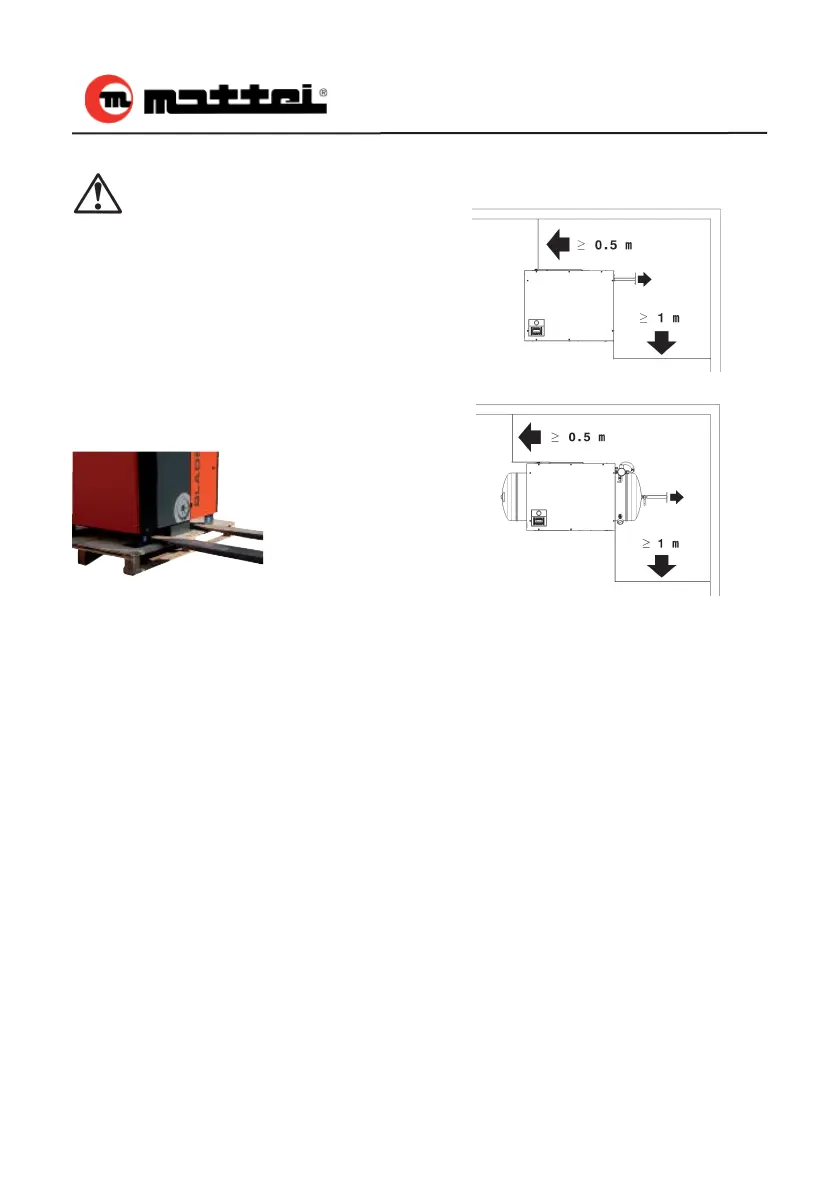

Position of compressor

Section “Technical Data” gives overall

dimensions, total weight, and values on the

cooling of the machine.

The machine should be installed in a covered

environment, properly ventilated, away form

heat sources and simply put on a solid and

level fl oor. It does not require any type of

special foundation.

Space and ventilation around the machine are

essential.

An air-cooled electric motor driven

compressor generates heat equal to about

85% of the absorbed power. The BLADE

Series machines, which have cooling air

outlet opening on the side of the structure,

shall be positioned at not less than 1 meter

from the wall.

If such a clearance is not possible, a hot air

vent duct must be installed (see further on

the section on the size of the ducts and heat

recovery).

Keep 0.5 meter distance – with no obstruction

– also on the rear side, where suction takes

place.

To make checks and maintenance operations

Loading...

Loading...