100 AGR 055A through 100A IOMM AGR

due to a clogged filter-drier or a restriction elsewhere in the liquid line See Table 55 for maximum

allowable pressure drops. If subcooling is low add charge to clear the sightglass. If subcooling is

normal (10°-15°F) and flashing is visible in the sightglass check the pressure drop across the filter-

drier. Subcooling should be checked at full load with 70°F (21.1°C) outdoor air temperature and all

fans running.

An element inside the sightglass indicates the moisture condition corresponding to a given element

color. If the sightglass does not indicate a dry condition after about 12 hours of operation, the

circuit should be pumped down and the filter-drier changed.

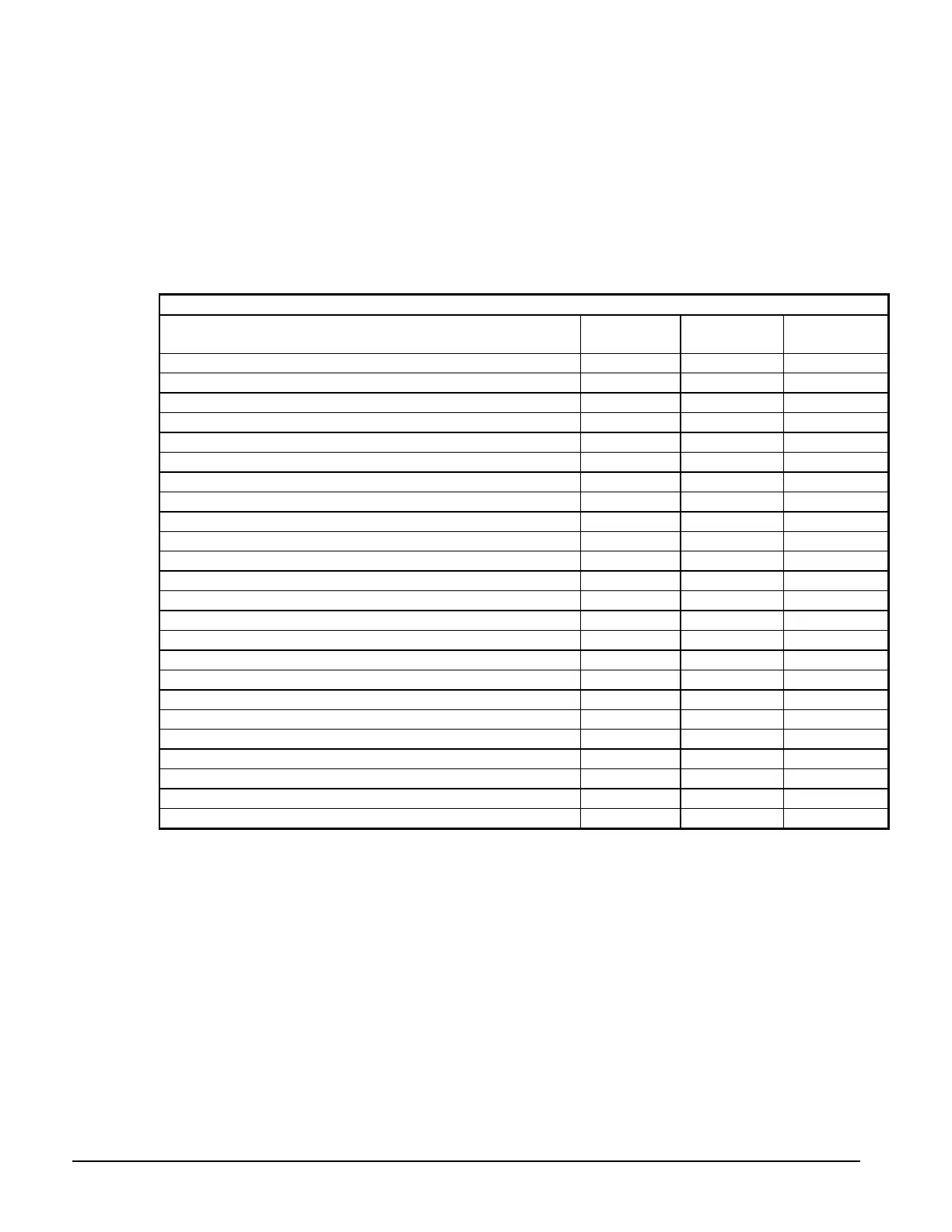

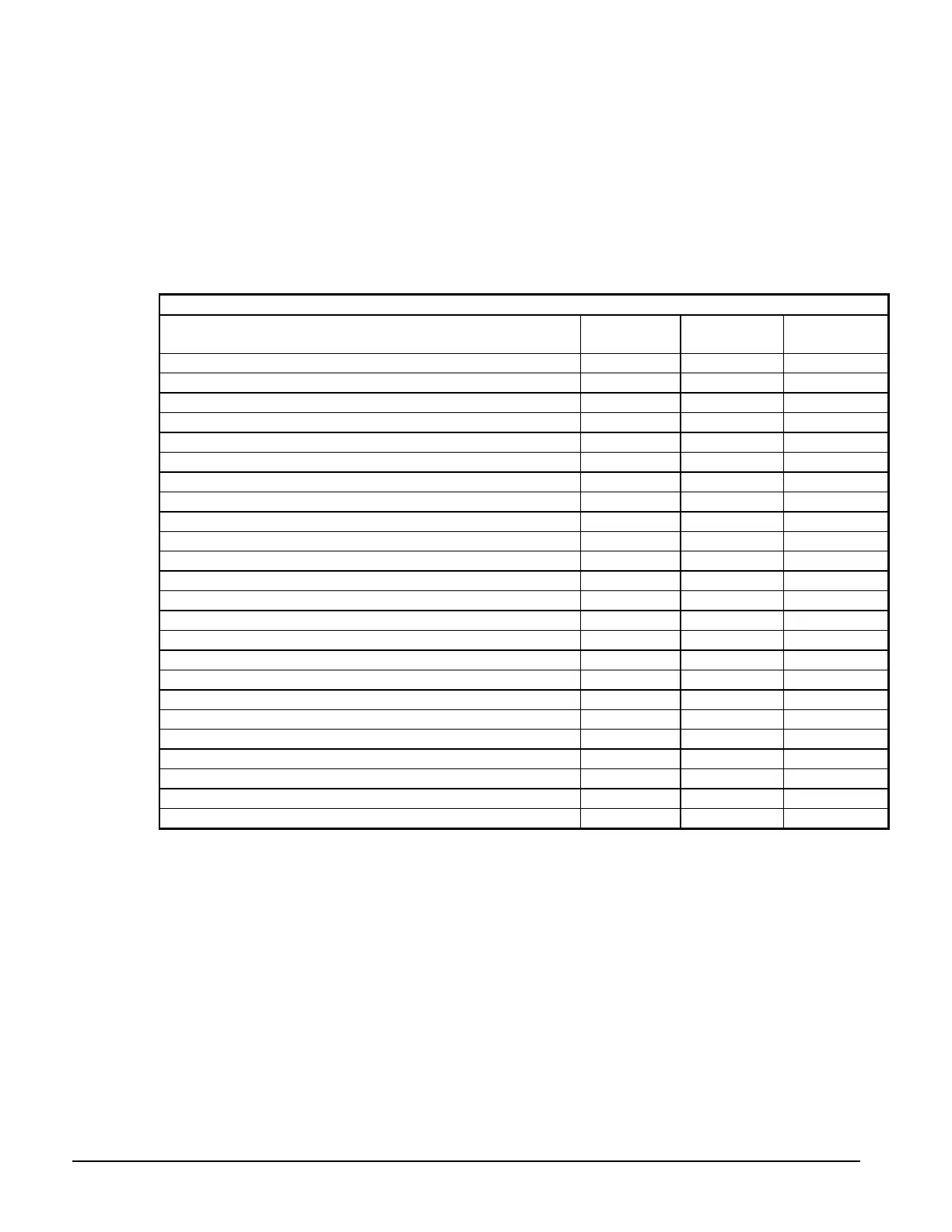

Preventative Maintenance Schedule

PREVENTATIVE MAINTENANCE SCHEDULE

OPERATION WEEKLY MONTHLY

(Note 1)

ANNUAL

(Note 2)

General

Complete unit log and review (Note 3) X

Visually inspect unit for loose or damaged components X

Inspect thermal insulation for integrity X

Clean and paint as required X

Electrical

Check terminals for tightness, tighten as necessary X

Clean control panel interior X

Visually inspect components for signs of overheating X

Verify compressor heater operation X

Megger compressor motor every five years (Note 6)

Test and calibrate all safety and operating controls X

Refrigeration

Leak test X

Check sight glasses for clear flow X

Check filter-drier pressure drop (see manual for spec) X

Condenser (air-cooled)

Clean condenser coils (Note 4) X

Check fan blades for tightness on shaft (Note 5) X

Check fans for loose rivets and cracks X

Check coil fins for damage X

Notes:

1. Monthly operations include all weekly operations.

2. Annual (or spring start-up) operations includes all weekly and monthly operations.

3. Log readings may be taken daily for a higher level of unit observation.

4. Coil cleaning may be required more frequently in areas with a high level of airborne particles.

5. Be sure fan motors are electrically locked out.

6. Caution: Do not Megger motor while in a vacuum.

Loading...

Loading...