IOMM AGR AGR 055A through 100A 11

CAUTION

Do not use an automotive grade antifreeze. Industrial grade glycols must be used.

Automotive antifreeze contains inhibitors which will cause plating on the copper tubes

within the chiller evaporator. The type and handling of glycol used must be consistent with

local codes.

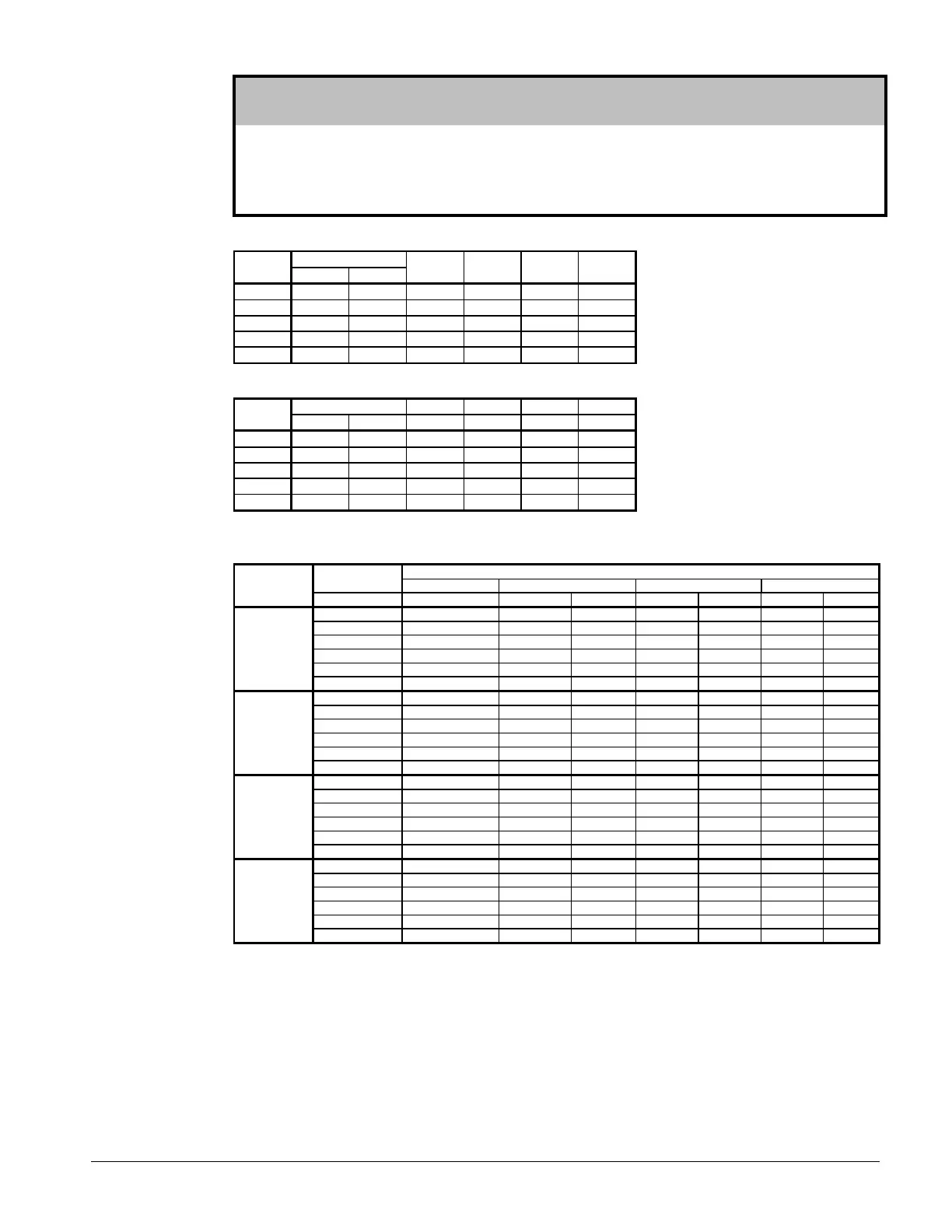

Table 4, Ethylene Glycol

% Freeze Point

E.G. °F °C Cap. kW GPM PD

10 26 -3 0.991 0.996 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Table 5, Propylene Glycol

% Freeze Point

P.G. °F °C Cap. kW GPM PD

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

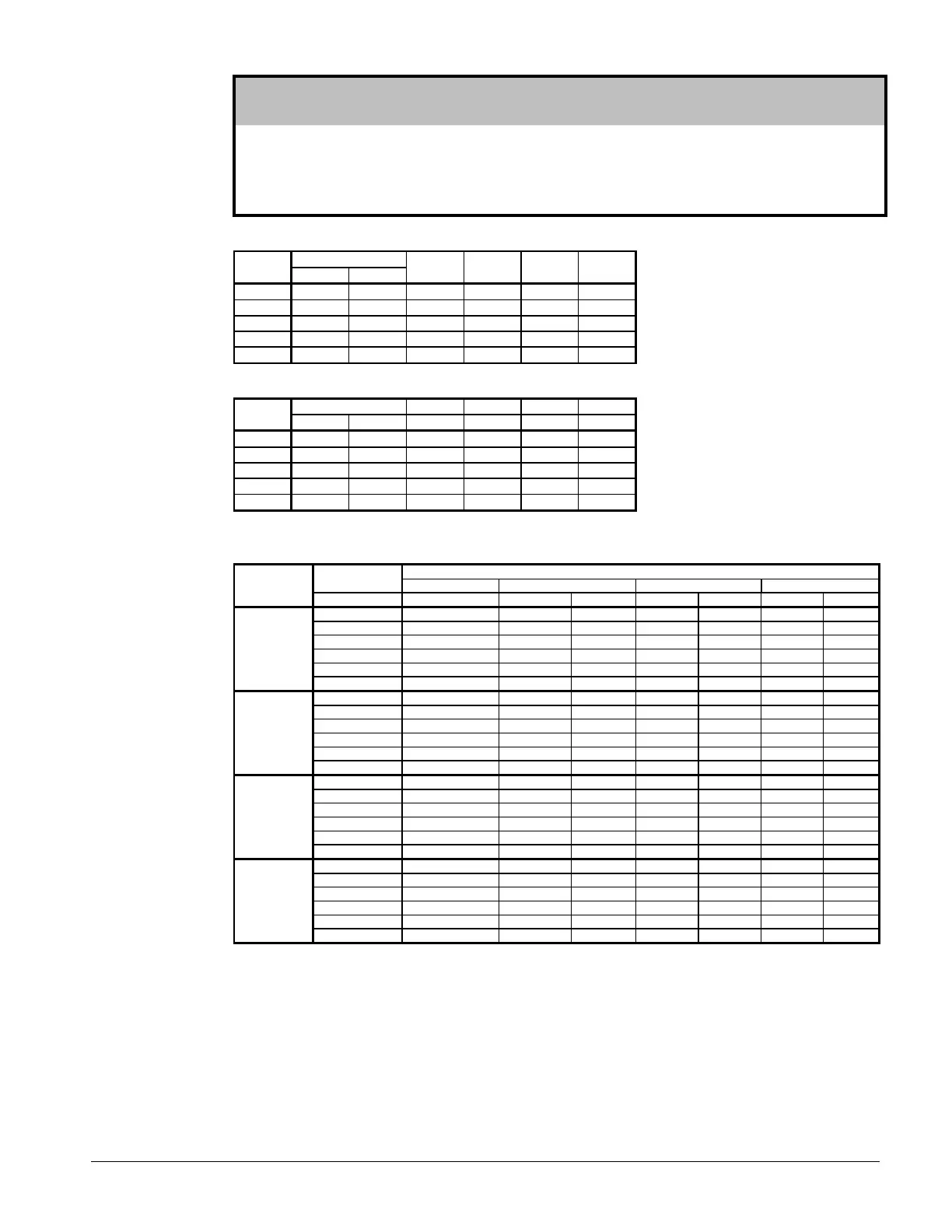

Table 6, Capacity and Power Derates

Chilled Water Fouling Factor

Delta-T 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

ALTITUDE °F °C Cap. kW Cap. kW Cap. kW

6 3.3 0.992 0.995 0.996 0.982 0.911 0.935

8 4.4 0.995 0.997 0.969 0.984 0.914 0.937

SEA 10 5.6 1.000 1.000 0.975 0.986 0.919 0.939

LEVEL 12 6.7 1.005 1.002 0.980 0.989 0.923 0.941

14 6.8 1.010 1.005 0.985 0.991 0.928 0.943

16 8.9 1.014 1.007 0.989 0.993 0.930 0.944

6 3.3 0.978 1.005 0.957 0.990 0.903 0.943

8 4.4 0.982 1.007 0.961 0.993 0.905 0.945

10 5.6 0.986 1.009 0.965 0.995 0.909 0.947

2000 feet 12 6.7 0.992 1.011 0.970 0.998 0.914 0.949

14 6.8 0.997 1.014 0.973 1.001 0.919 0.952

16 8.9 1.000 1.016 0.975 1.002 0.921 0.953

6 3.3 0.966 1.016 0.944 0.999 0.894 0.951

8 4.4 0.969 1.018 0.947 1.001 0.896 0.953

10 5.6 0.973 1.021 0.952 1.005 0.900 0.956

4000 feet 12 6.7 0.978 1.025 0.956 1.008 0.904 0.958

14 6.8 0.982 1.027 0.959 1.011 0.909 0.960

16 8.9 0.986 1.028 0.961 1.015 0.911 0.961

6 3.3 0.953 1.025 0.930 1.009 0.884 0.961

8 4.4 0.955 1.028 0.934 1.011 0.887 0.962

10 5.6 0.959 1.031 0.939 1.013 0.890 0.964

6000 feet 12 6.7 0.963 1.034 0.942 1.017 0.895 0.966

14 6.8 0.968 1.036 0.946 1.020 0.899 0.968

16 8.9 0.972 1.037 0.949 1.024 0.902 0.969

Loading...

Loading...