IOMM AGR AGR 055A through 100A 43

Software Description (Global UNT Interface Kit required to read or

change variables)

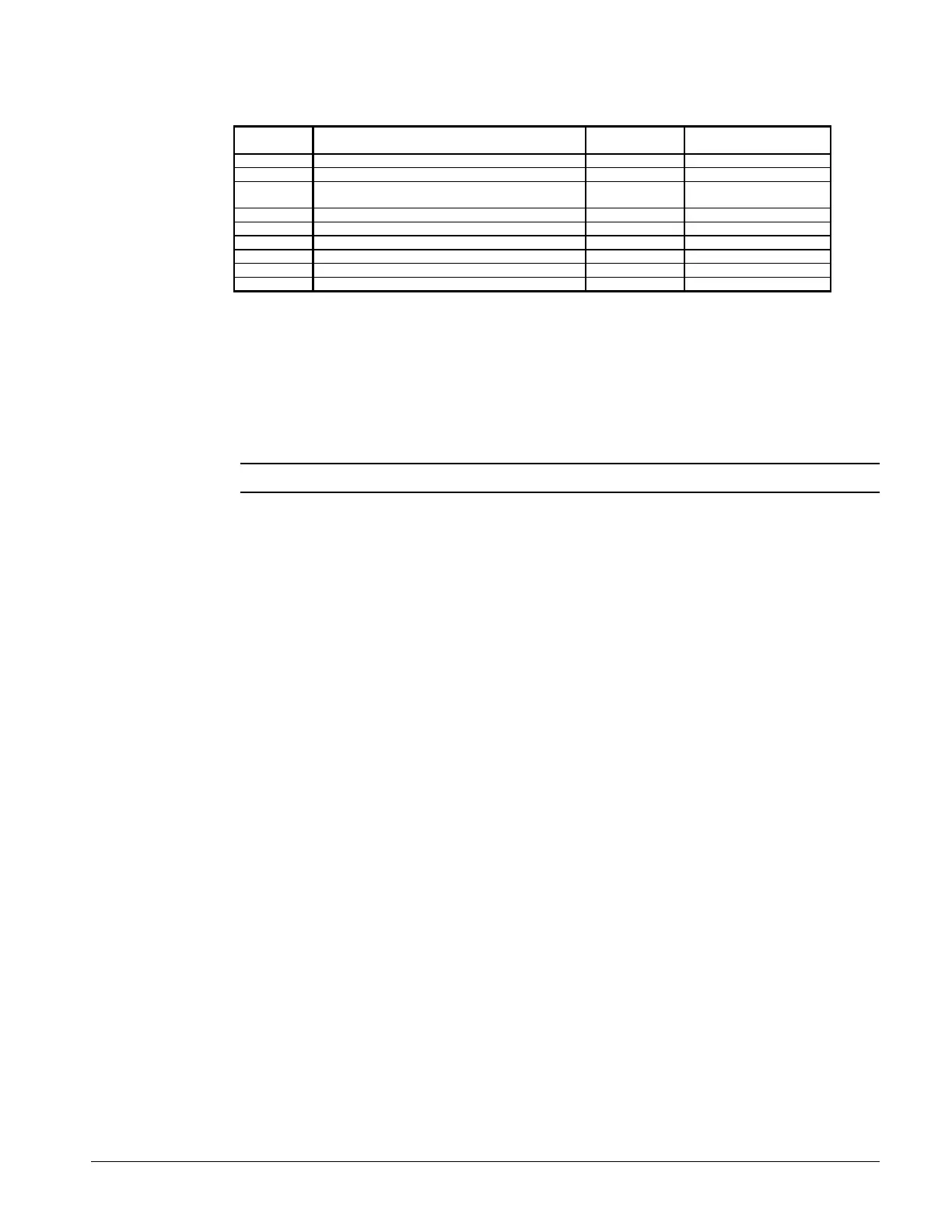

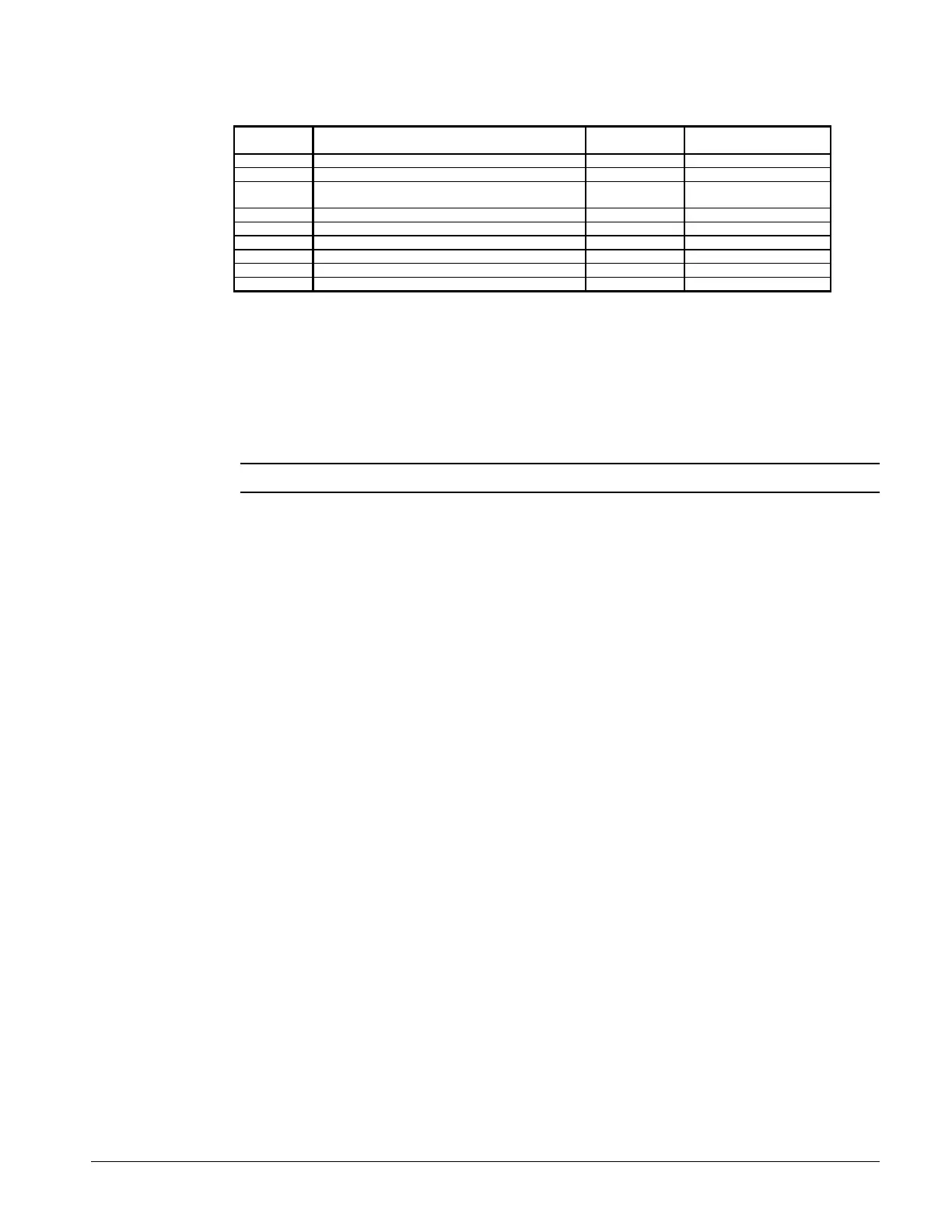

Variable

Name

Description Default Value Range

LPSS Low Pressure Starting Setpoint 10 psi 5 to 15 psi

SLPT Starting Low Pressure Time 260 sec 90 to 300 seconds

MLPS Minimum Low Pressure Setpoint 5 psi Calculated (LPSS-LPSD)

5 psi

LPSD Low Pressure Starting Differential 5 psi 3 to 10 psi

LPFS Low Pressure Freezestat setpoint 54 psi 30 to 55 psi

LPHL Low Pressure High Limit 57 psi 40 to 60 psi

LPLL Low Pressure Low Limit 55 psi 40 to 55 psi

FSTP Freezestat Time Period 60 sec 60 seconds fixed

PDTD Pumpdown Delay Time Period 60 sec 60 seconds fixed

Hot Gas Bypass (Optional)

This option allows the system to operate at low loads without the ON-OFF cycling of the

compressor. When the hot gas bypass option is used it is required to be on both refrigerant circuits

because of the lead / lag feature of the Global UNT controller.

This option allows passage of discharge gas into the evaporator inlet (between the TX valve and the

evaporator) which generates a false load to supplement the actual chilled water load.

Note: The hot gas bypass valve cannot generate a 100% false load.

The valve that is supplied can provide a load of approximately 10 tons. The system load added to

the ten tons of the hot gas bypass valve has to exceed the compressor capacity for stage 1 compressor

operating unloaded for stable system operation. This requires some system load. When using hot

gas bypass, the optional six stage capacity staging unit is recommended.

A solenoid valve in the hot gas bypass lines is wired in parallel with both circuit’s liquid line

solenoid valves SV1 and SV2. The hot gas bypass is available whenever a refrigerant circuit is

operating. The hot gas valve is regulating by the evaporator pressure and the remote adjustable

bulb. The pressure regulating valve is factory set to begin opening at 58 psig (32°F for R-22). This

setting can be changed by adjusting the remote adjustable bulb. Remove the cap on the remote bulb

and raise the pressure by turning the adjustment screw clockwise. Lower the pressure by turning the

adjusting screw counterclockwise. This changes the pressure that the hot gas bypass valve will start

to open. Do not force the adjusting screw as this can damage the adjusting assembly.

NOTE: The hot gas line may become hot enough to cause injury. Be careful during valve

checkout.

NOTE: The remote adjusting bulb must be installed on the outside of the suction line

insulation. The bulb has to have a stable ambient air temperature for proper operation.

Placing the bulb in contact with the evaporator refrigerant line will limit the operation of the

hot gas bypass valve.

Filter Driers

Each refrigerant circuit is furnished with a full flow filter drier or an optional replaceable core type

filter-drier. The core assembly of the replaceable core drier consists of a filter core held tightly in

the shell in a manner that allows full flow without bypass.

Pressure drop across the filter drier at full load conditions must not exceed 10 psig. If pressure

drop is more than 10 psig, then replace the filter drier.

NOTE: Pump out refrigerant before removing end flange for replacement of core(s).

A condenser liquid line service valve is provided for isolating the charge in the condenser, but also

serves as the point from which the liquid line can be pumped out. With the line free of liquid, the

filter-drier core(s) can be easily replaced.

Loading...

Loading...