10 McQuay IM 660-3

Diagnostic Service

Unit Identification (Wink) Command

The unit identification function allows verification of an

individual unit network address without opening the unit

access panels. The compressor shuts off during this period and

the minimum off timer must expire before the compressor is

allowed to run again.

Upon receiving a “wink” command from a network

management node, the heat pump exhibits the following

identification sequence (status LED and fan sequences occur

simultaneously):

• Status LED: Flashes (on 0.5 sec, off 0.5 sec) for 15 seconds.

• Fan: The heat pump fan turns off for 5 seconds, turns on for

5 seconds, then off again for 5 seconds.

Alarm Monitoring and Control

The water source heat pump controller is programmed to

monitor the water source heat pump for specific alarm

conditions that may occur on the various model types. If an

alarm condition exists and is detected by the controller, a

“fault” occurs. The water source heat pump controller

indicates that a fault has occurred at the status LED (on-board

or remote) and executes appropriate control actions for the

alarm conditions.

During a fault condition, the status LED flashes constantly (on

0.1 second, off 0.1 second) until the fault is cleared. Refer to

“Test Procedures” on page 12 of the “Service Information”

section for information on troubleshooting digital input faults.

Clearing Faults

Before any fault can be cleared, the alarm conditions that

caused it must have returned to normal. When the alarm

conditions are gone, a fault may be cleared either

automatically or manually, as follows.

• An auto reset fault immediately clears whenever the alarm

conditions that caused it disappear.

• To clear a manual reset fault, cycle power to the controller.

Note – Investigate and eliminate the cause of a manual reset

fault before placing the unit back into service.

Alarm Fault Descriptions

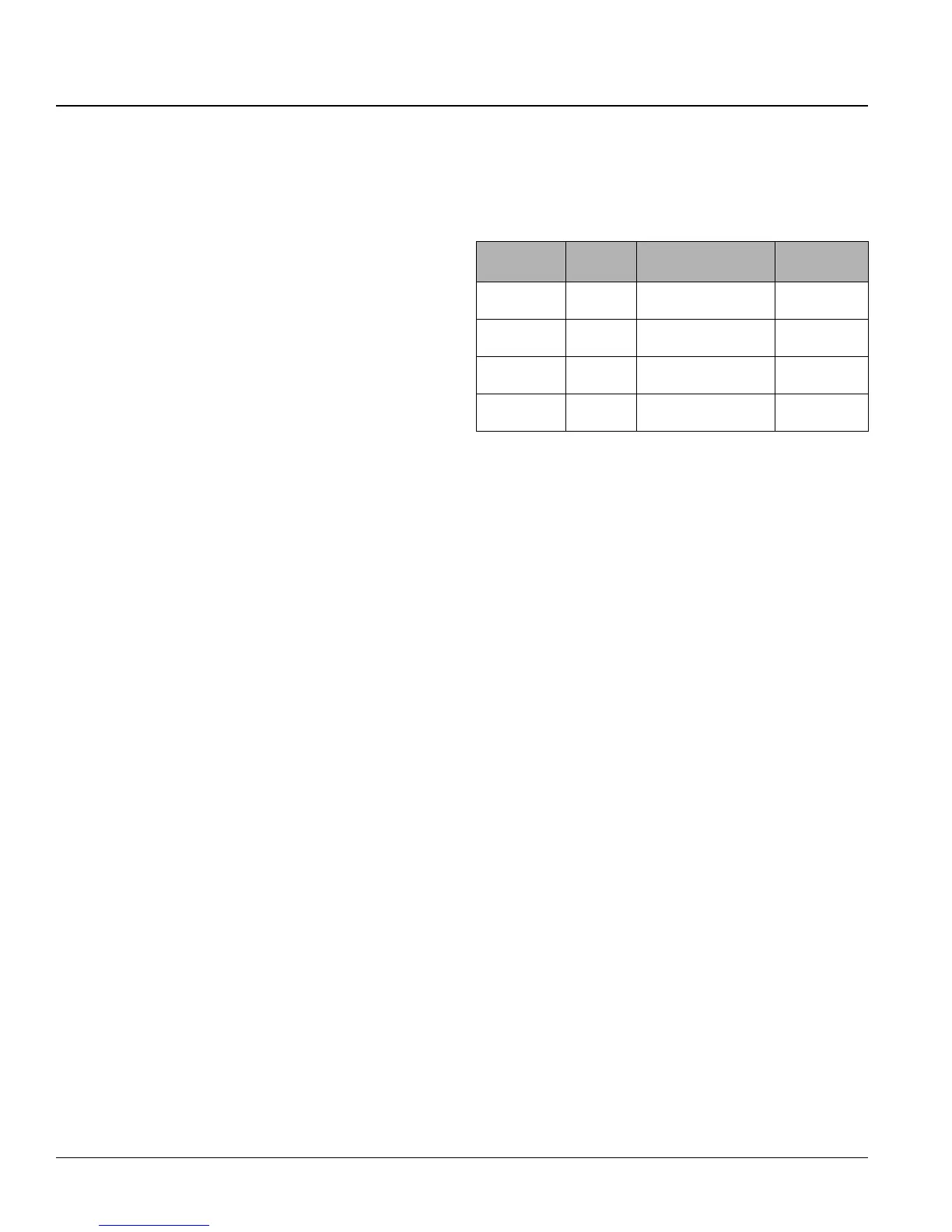

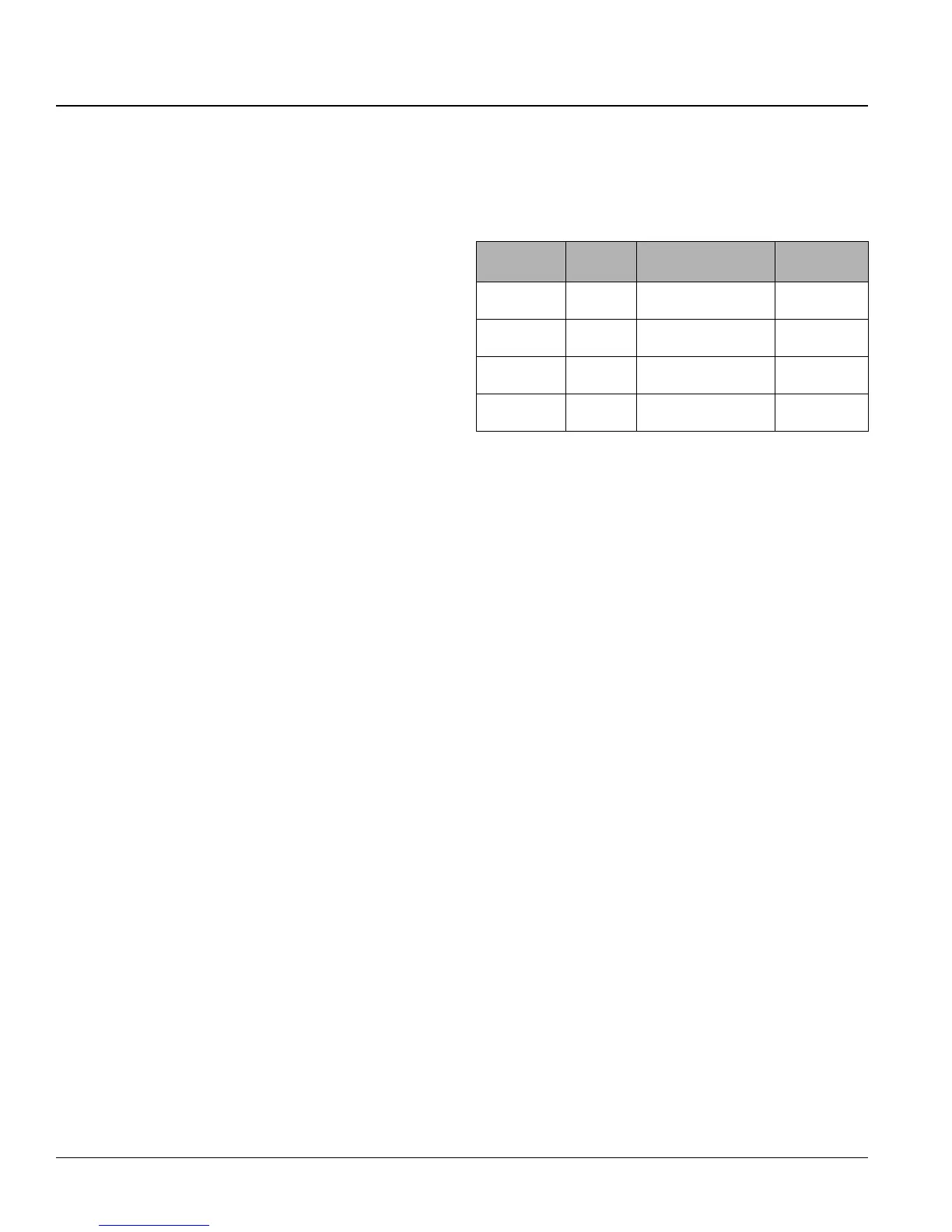

Table 6 below describes the alarm faults, how they are

triggered, the factory settings that trigger them and how they

are reset. A detailed discussion of each follows.

High Pressure Fault

The “High Pressure” fault indicates that the high pressure

switch input (J4-9) sensed an open circuit while the controller

was calling for the compressor to run.

The high pressure switch (HP) is wired in series with the

compressor relay output (J4-5) and the compressor relay coil.

Therefore, if a high pressure condition occurs, the switch

immediately shuts down the compressor; then unit operation is

disabled by the WSHP controller software. For information on

troubleshooting digital input faults, see “Test Procedures” on

page 12.

Effects (as applicable):

• The compressor immediately de-energizes.

• The software disables normal unit operation until the fault

condition is manually corrected.

Low Temperature Fault

The “Low Temperature” fault indicates that the low

temperature switch input (J4-12) sensed an open circuit while

the controller was calling for the compressor to run.

The low temperature switch opens when the temperature falls

below its set point (model and size dependent). For

information on troubleshooting digital input faults, see “Test

Procedures” on page 12.

Effects:

• Unit changes to cooling for 60 seconds for coil defrost.

• After 60 seconds in cooling, the software immediately

de-energizes the compressor and fan.

• The software disables normal unit operation until the fault

condition is manually corrected.

Table 6: Alarm and fault code summary

Fault Trigger Factory setting

Fault reset

(Clear)

High pressure Hardware

Opens at 395 ± 10 psig

Closes at 250 ± 25 psig

Manual

Low pressure Hardware

Opens at 7 ± 3 psig

Closes at 22 ± 7 psig

Manual

Condensate

overflow

Hardware

Conductivity trip point:

2.5 micro ohms

Manual

Brownout Software

Line voltage ± 82%of

nameplate voltage

Auto

Loading...

Loading...