R410A 60Hz 16 SEER Universal Outdoor Series Technical Manual

4. Insulation Work

4.1 Insulation material and thickness

4.1.1. Insulation material

Insulation material should adopt the material which is able to endure the pipe’s temperature: no less than 70℃

in the high-pressure side, no less than 120℃ in the low-pressure side(For the cooling type machine, no

requirements at the low-pressure side.)

◆ Example: Heat pump type----Heat-resistant Polyethylene foam (withstand above 120℃)

Cooling only type----Polyethylene foam (withstand above 100℃)

4.1.2. Thickness choice for insulation material

Insulation material thickness is as follows:

Adiabatic material thickness

4.2 Refrigerant pipe insulation

4.2.1. Work Procedure

① Before laying the pipes, the non-jointing parts and non-connection parts should be heat insulated.

② When the gas proof test is eligible, the jointing area, expanding area and the flange area should be heat

insulated.

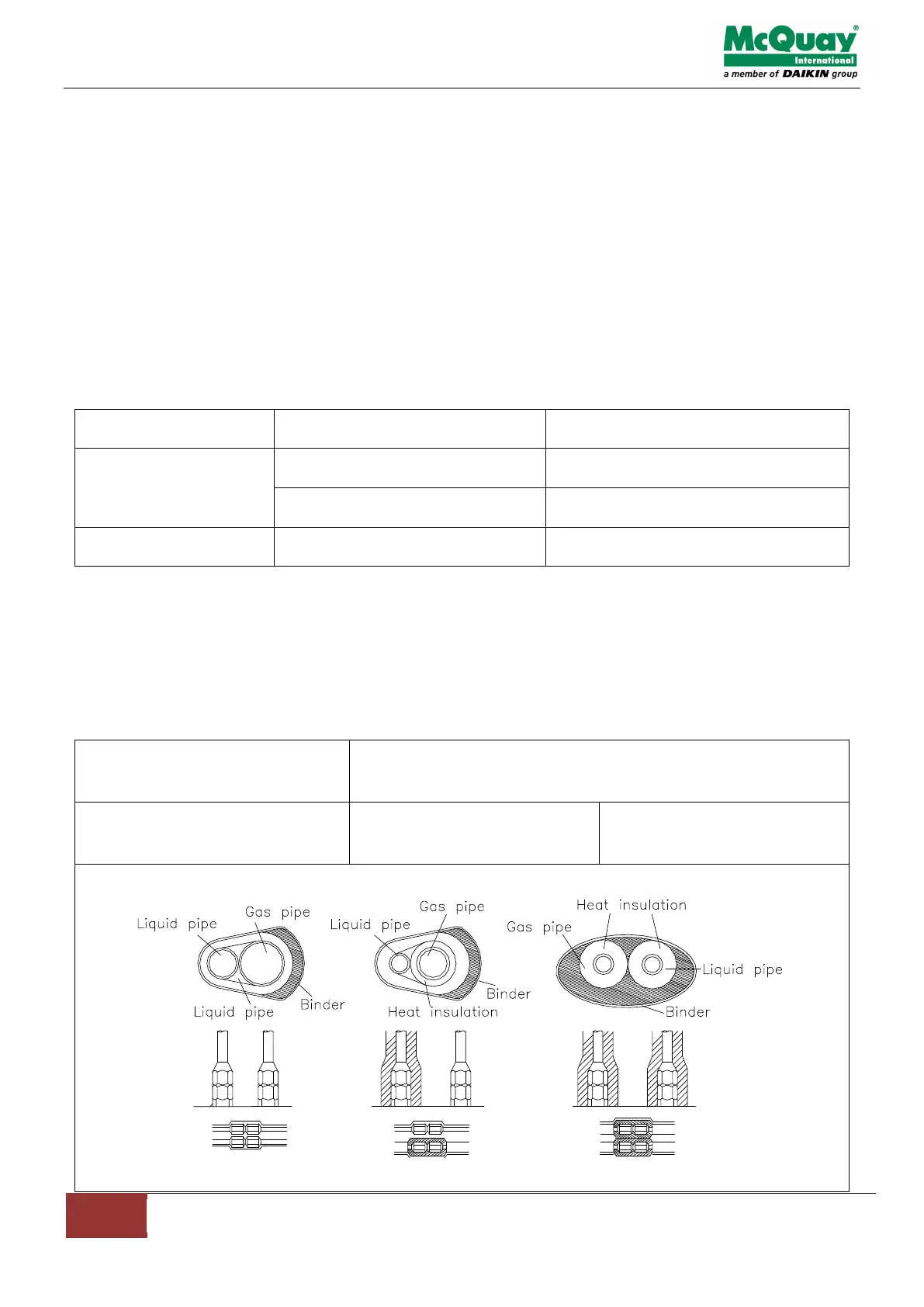

4.2.2. Insulation for non-jointing parts and non-connection parts

Gas pipe and liquid pipe should

not be put together to insulate

Insulate the gas pipe

(cooling only)

Insulate the gas pipe and

liquid pipe

Loading...

Loading...