2.6 Instrument air supply

CAUTION:

Do not exceed the permitted actuator supply air

pressure!

The supply air must be clean, dry and oil-free instrument air, e.g.

according to standard ISA S7.3-81. Supply pressure is 0.14-1.0 MPa

/ 1.4-10 bar (20-140 psi).

3 INPUT SIGNAL AND DIRECTIONS

OF OPERATION

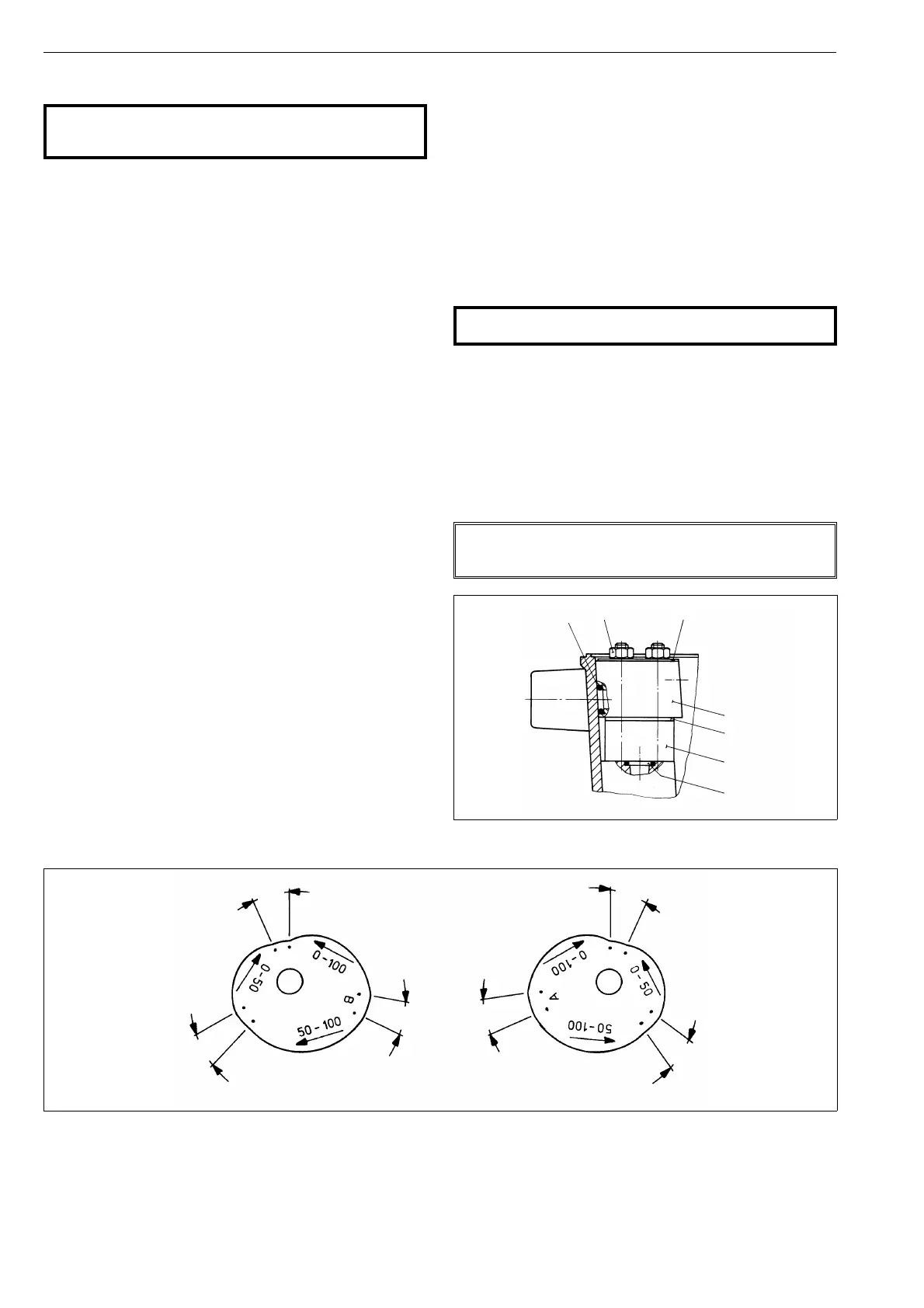

Figure 4 assists in choosing the right segment for the cam plate (29)

and position for the changeover piece (46).

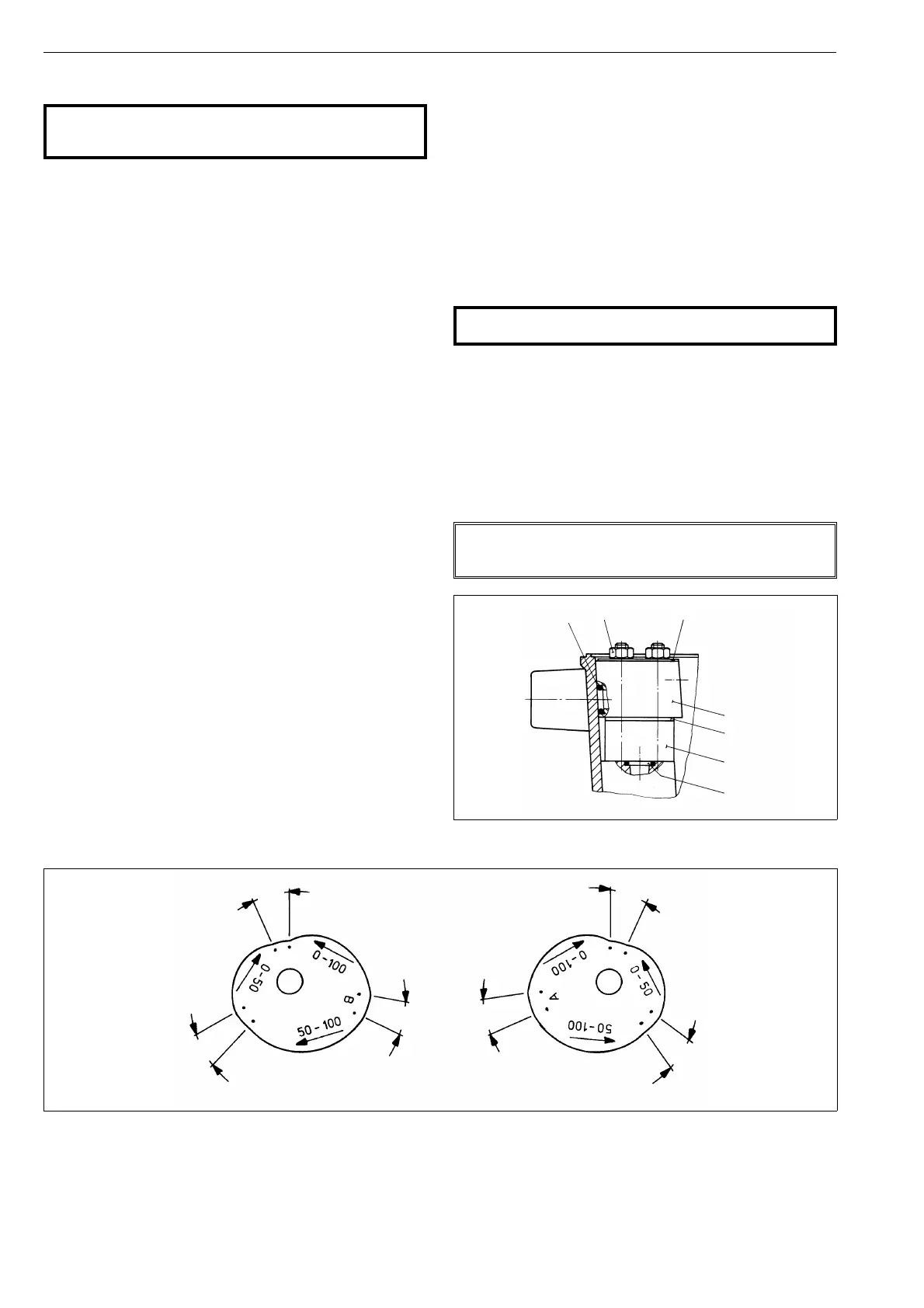

3.1 Changeover piece

The function of connection C1 and C2 can be altered by turning

the changeover piece (46). The diagram D (or R) shown on the

protective plate (48) functions when the symbol D (or R) is

visible in the lower lefthand corner of the changeover piece (46).

D = direct, R = reverse.

External changes in the tubes are not needed. Positioner NP727 is

an exception (DIA6HC pilot valve). Then the changeover piece

must always be in position R and the external tubes mounted in

accordance with Fig. 7.

3.2 Cam plate

The figures marked on the cam plate (29) are the signal ranges

expressed as percentages, for example 0-100 corresponds to 20-100

kPa (3-15 psi), or 50-100 to 60-100 kPa (9-15 psi), see Fig. 8.

The arrows on the cam show the direction it must turn when the

input signal is rising in the cam segment in question.

The non-rising segments between the rising segments are

roughly 15-20º.

4 PRELIMINARY ACTIONS FOR THE

ADJUSTMENT

Set the valve’s open and closed limits with the actuator limiter screws; see

the valve instruction manual. The changeover piece (46) and the cam (29)

must be in correct positions. Check the pilot valve size from Table 2.

The adjustment must always be carried out when the supply

pressure has been changed.

Please note that operating of the valve is required during the

adjustment.

4.1 Position of the changeover piece

CAUTION:

Do not dismantle a pressurized positioner!

Choose the position of the changeover piece, D or R, from Fig. 7

in accordance with the function desired.

Turn the changeover piece (46) when necessary.

Loosen the nuts (49) and remove the protective plate (48). Pull out

the changeover piece (46). Check the O-rings (47, 2 pcs.) and apply

silicone grease lightly if needed. Place the changeover piece (46) and

the protective plate (48) in the case. Tighten the nuts (49) evenly,

one after the other.

NOTE:

Check that the changeover piece is mounted correctly: Sym-

bol D or R is visible in the lower left hand corner.

60-100 kPa (9-15 psi)

rising signal opens

60-100 kPa (9-15 psi)

rising signal closes

20-100 kPa (3-15 psi)

rising signal closes

20-100 kPa (3-15 psi)

rising signal opens

20-60 kPa (3-9 psi)

rising signal closes

20-60 kPa (3-9 psi)

rising signal

opens

segment C

segment C

segment E

segment D

segment E

~ 15°

~ 15°

~ 15°

~ 15°

~ 15°

~ 15°

Fig. 8. Input signal ranges

48

47

49

43

44

45

46

Fig. 9. Mounting the changeover piece

8

Loading...

Loading...