7 NP 72 en 5

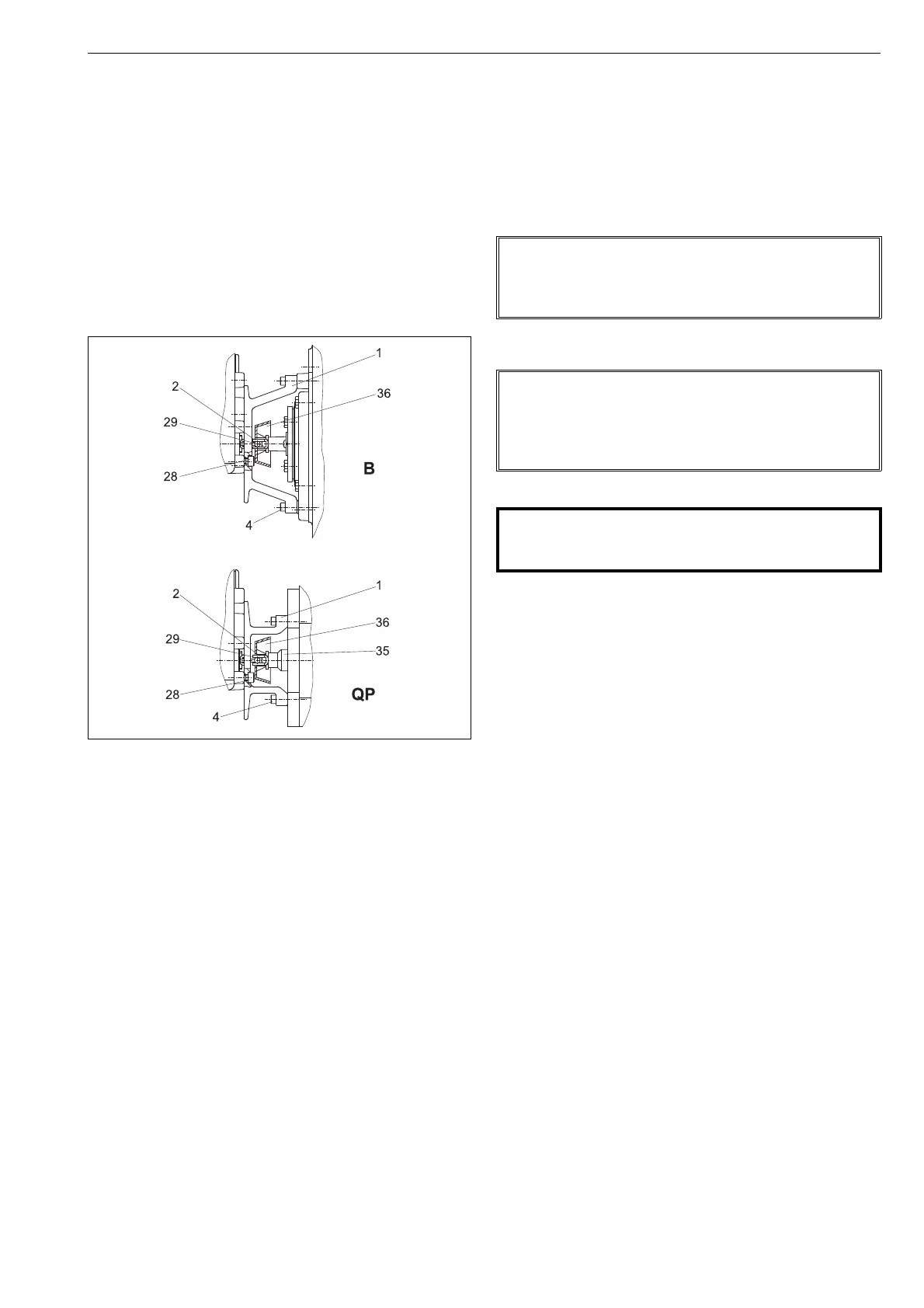

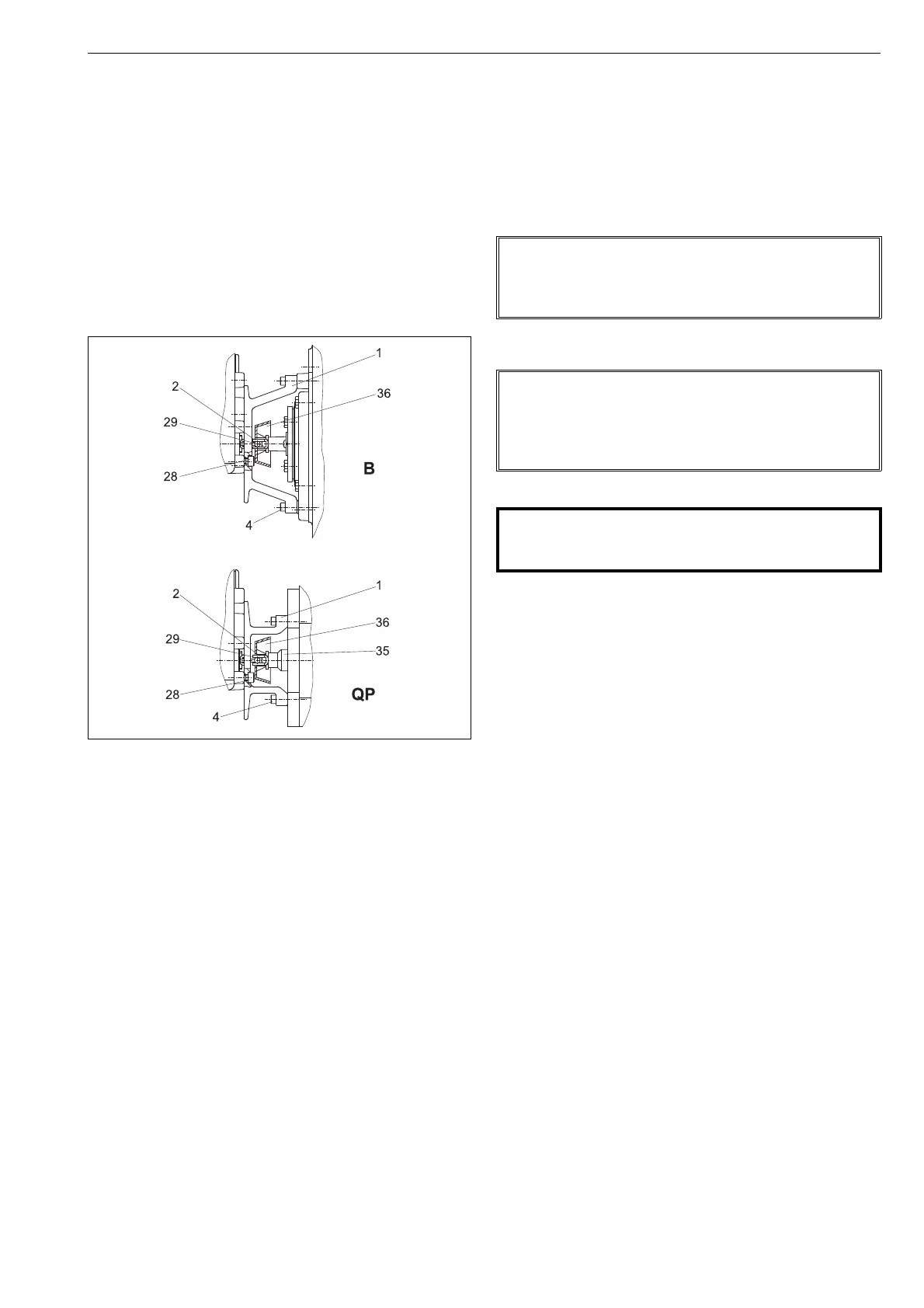

2.2 Installing positioner NP700/S1 on

Metso actuators with VDI/VDE 3845

mounting face

1. The actuator piston must be in the up position (in spring-

return actuators as determined by the spring).

2. Install the pointer (only B_U) parallel with the valve clo-

sure member and fasten the draught piece (2) with a

screw (29) to the pointer cover (B_U) or to the coupling

(QP), as shown in Fig. 4. Secure the draught piece fasten-

ing screw with a sealant (e.g. Loctite) and tighten it

properly.

3. Fasten the mounting bracket (1) to the positioner.

4. Fasten the mounting bracket (1) to the actuator.

2.3 NP_700/700 positioner/limit switch

combination (Obsolete since 2013)

The bottom of the limit switch acts also as the cover for the

positioner. Remove the limit switch before the adjustment

of the positioner.

1. Loosen the cover screws. Note the position of the shaft

relative to the positioner when removing the limit switch.

2. When the adjustment of the positioner is done, operate

the actuator until the valve is in the closed or open posi-

tion.

3. Note the position of the actuator and valve when

mounting the limit switch on the actuator. Make sure

that the position of the shaft is unchanged relative to

the positioner.

4. Place the limit switch on the positioner so that the

shafts are correctly engaged.

5. Fasten the cover screws.

6. Check the adjustment of the limit switch. See the

instruction manual of the limit switch for details.

2.4 Piping of supply air

Table 2 provides the recommended pilot valve and tube

sizes in accordance with the actuator sizes. Tube sizes are

minimum values allowed.

Connect air supply to S (1/4 NPT).

Connect C1 and C2 (1/4 NPT) to the actuator according to

Fig. 5. See also Chapter 3.

Connect signal air to IN (1/4 NPT).

For pipe threads are liquid sealants, e.g. Loctite, recom-

mended.

2.5 Instrument air supply

The supply air must be clean, dry and oil-free instrument air,

e.g. according to standard ISA S7.3-81. Supply pressure is

1.4–10 bar (20–140 psi).

Fig. 4 Installing on a Metso actuator (S1)

NOTE:

A single action connection alone is permitted for position-

ers mounted on the spring actuator!

Place a plug in connection C1 or C2. See Figure 5.

NOTE:

Exessive sealant may cause faulty operation of the posi-

tioner.

Sealing tape is not recommended.

Ensure the cleaness of the air piping.

CAUTION:

Do not exceed the permitted actuator supply air pres-

sure!

Loading...

Loading...