7 NP 72 en 9

Loosen the screw (57), remove the indicator (32), loosen the

screw (31) and the locking wheel (30). Turn the cam plate

(46) to the desired side.

In case of α

0

adjustment proceed acc. to Sections 6.1 and

6.2.

Place the roller so that its contact point is 1 mm (0.04") from

the beginning of the rising segment. Then tighten the lock-

ing wheel (30) and the screw (31).

5 BASIC ADJUSTMENT

Basic adjustment is made to rotary and butterfly valves.

Please note the procedures in Chapter 4 before the adjust-

ment.

1. Switch on the supply pressure (S) and the input signal

(IN).

2. Set the input signal at the closed limit of the valve so

that it is 2 % i.e. 0.02 bar (0.2 psi) higher or lower than

the limit value, e.g. 0.2 + 0.02 = 0.22 bar (3 + 0.2 = 3.2 psi)

or 1.0 - 0.02 = 0.98 bar (15 - 0.2 = 14.8 psi). Loosen the

screw (56). Turn the zero adjustment screw (67) so that

the actuator comes slowly to the closed limit. Tighten

the screw (56) always after the zero adjustment. The

valve should open slightly with a 4 % change in signal,

that is 0.03 bar (0.5 psi), e.g. 0.2 + 0.03 = 0.23 bar (3 + 0.5

= 3.5 psi) or 1.0 - 0.03 = 0.97 bar (15 - 0.5 = 14.5 psi). See

Figures 8 and 9.

3. Set the input signal to the other limit value. The valve

should be entirely open at 100 %, i.e. 1.0 bar (15 psi) or

0.2 bar (3 psi). The valve should start to operate to

closed direction at 98 %, i.e. 0.98 bar (14.0 psi) or 0.22

bar (3.2 psi). The range, i.e. turning angle, changes when

the effective lenght of the spring (60) is increased or

decreased by turning the range adjustment nut (60.3).

See Fig. 9.

4. The zero and range adjustments affect each other, so

stages 2 and 3 must be repeated a few times.

5. Screw on the pointer (32) into place so that the yellow

line is in the direction of the valve closing member.

Tighten the screw (57).

6 α

0

ADJUSTMENT

α

0

adjustment is made to segment and ball valves. This

adjustment takes into account the "dead angle" α

0

of the

ball valve. The entire signal range is then used for effective

The same adjustment method can be applied to butterfly

valves in papermills for pulp flow control to avoid the dewa-

tering of the pulp near the closed position of the disc.

Table 3 shows the shift on the circumference of the cam

equal to the "dead angle" of the valve, Figure 11, in various

cam segments (C, E, D).

Please note the procedures in Chapter 4 before the adjust-

ment.

1. Mark the shift in question on the edge of the cam, Fig. 11

and Table 3. Dimensions do not have to be measured if

the dead angle can be reliably noticed from position of

the closing member.

2. Lock the cam so that the roller touches the edge of the

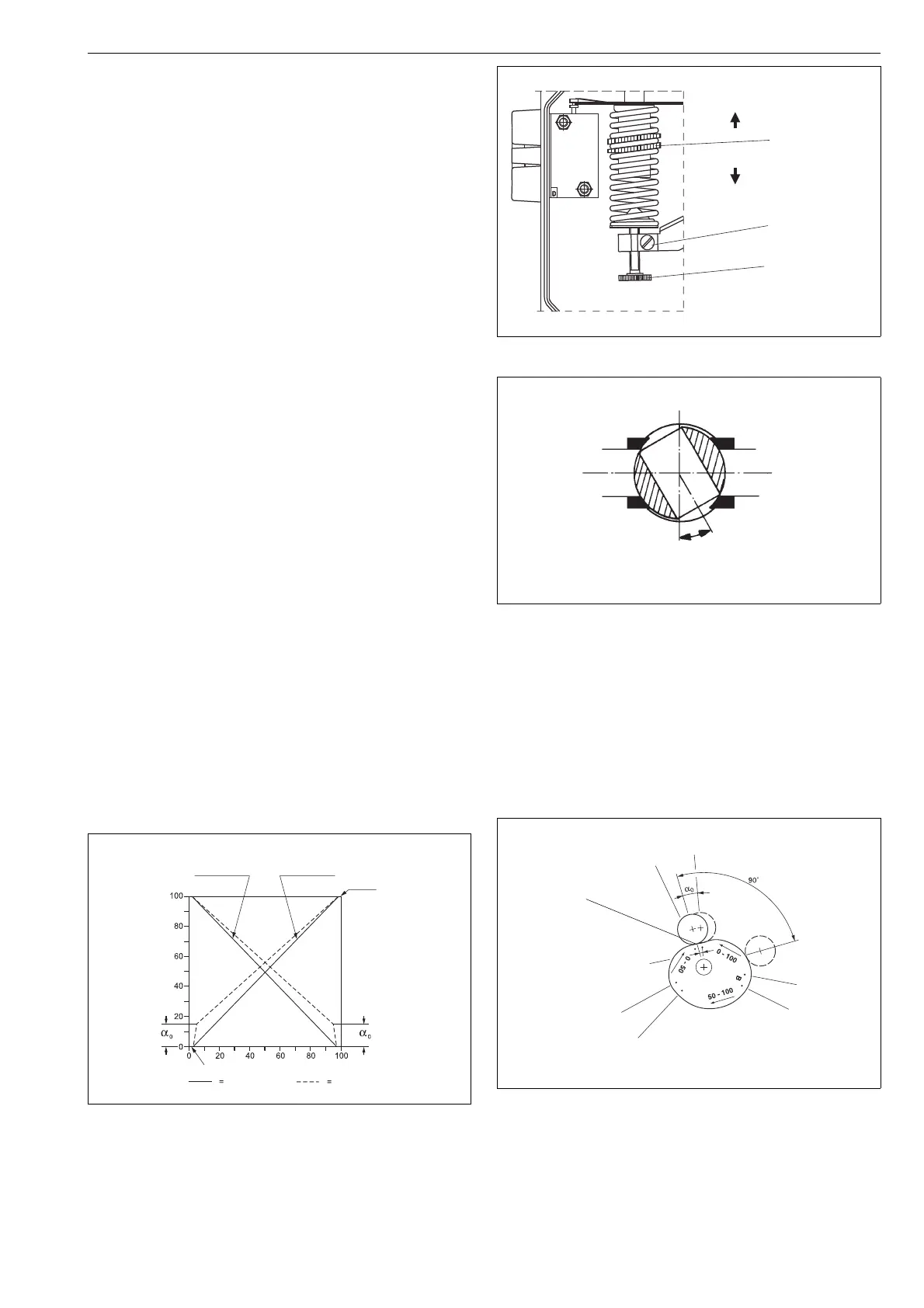

Fig. 8 Basic and

α

0

adjustments

POSITION %

Rising input signal closes valve

Rising input signal opens valve

max 2 %

INPUT SIGNAL %

safety range 2 %

Basic adjustment α

0

adjustment

Fig. 9 Zero and range adjustments

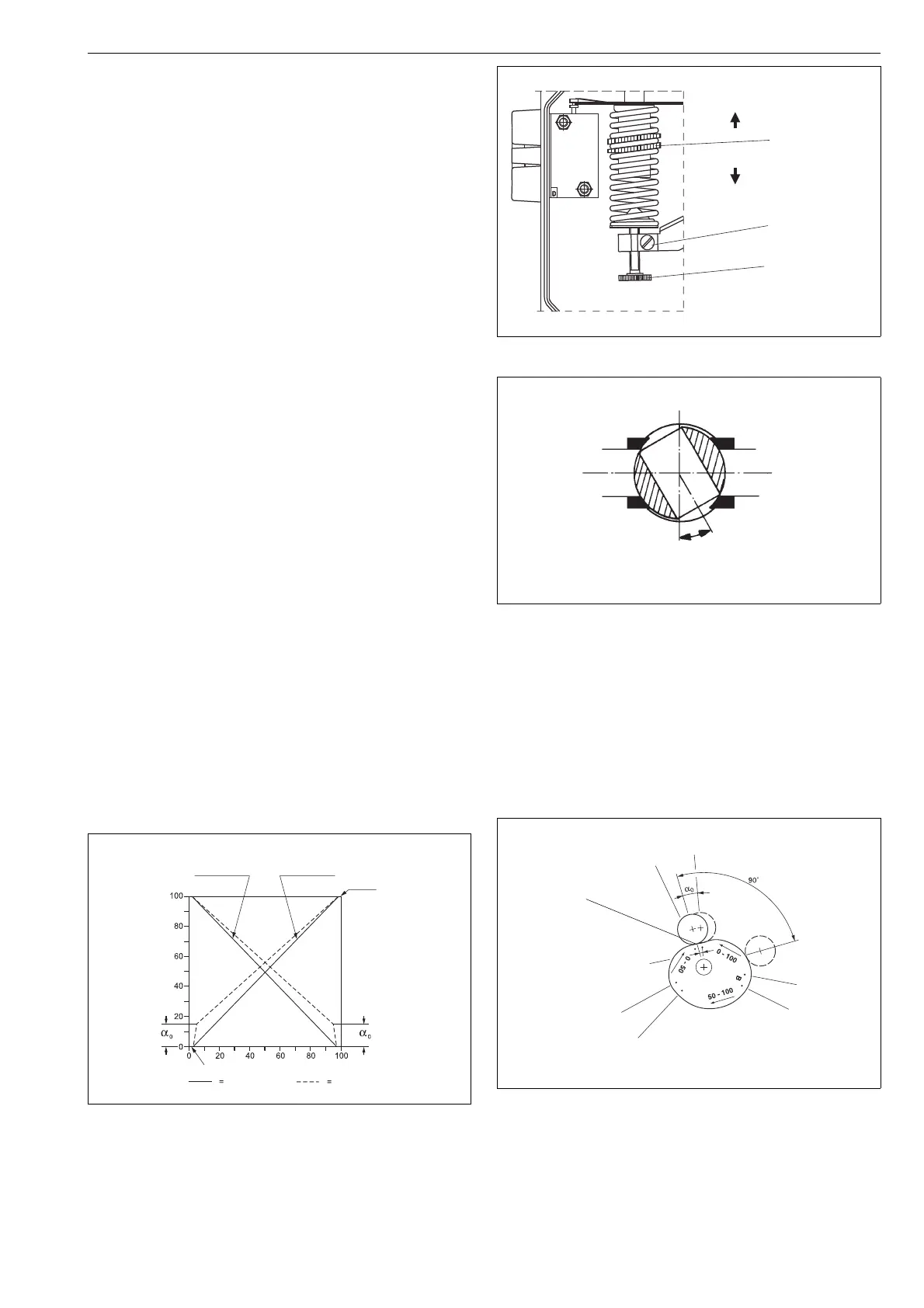

Fig. 10 Dead angle

Fig. 11 Shift on circumference of cam equal to dead angle

range increases

range

range decreases

screw (56)

zero adjustment (67)

adjustment (60.3)

segment D

segment C

segment E

shift

Roller contact point when

the ball is completely closed

Loading...

Loading...