'19 • PAC-SM-309

Error code

Remote control:

LED Green Red

1-time flashKeeps flashing

Stays OFFKeeps flashing

Content

Indoor unit

control PCB

Outdoor unit

control PCB

-

123

--

123

-

E49

1. Applicable model

5. Troubleshooting

All models

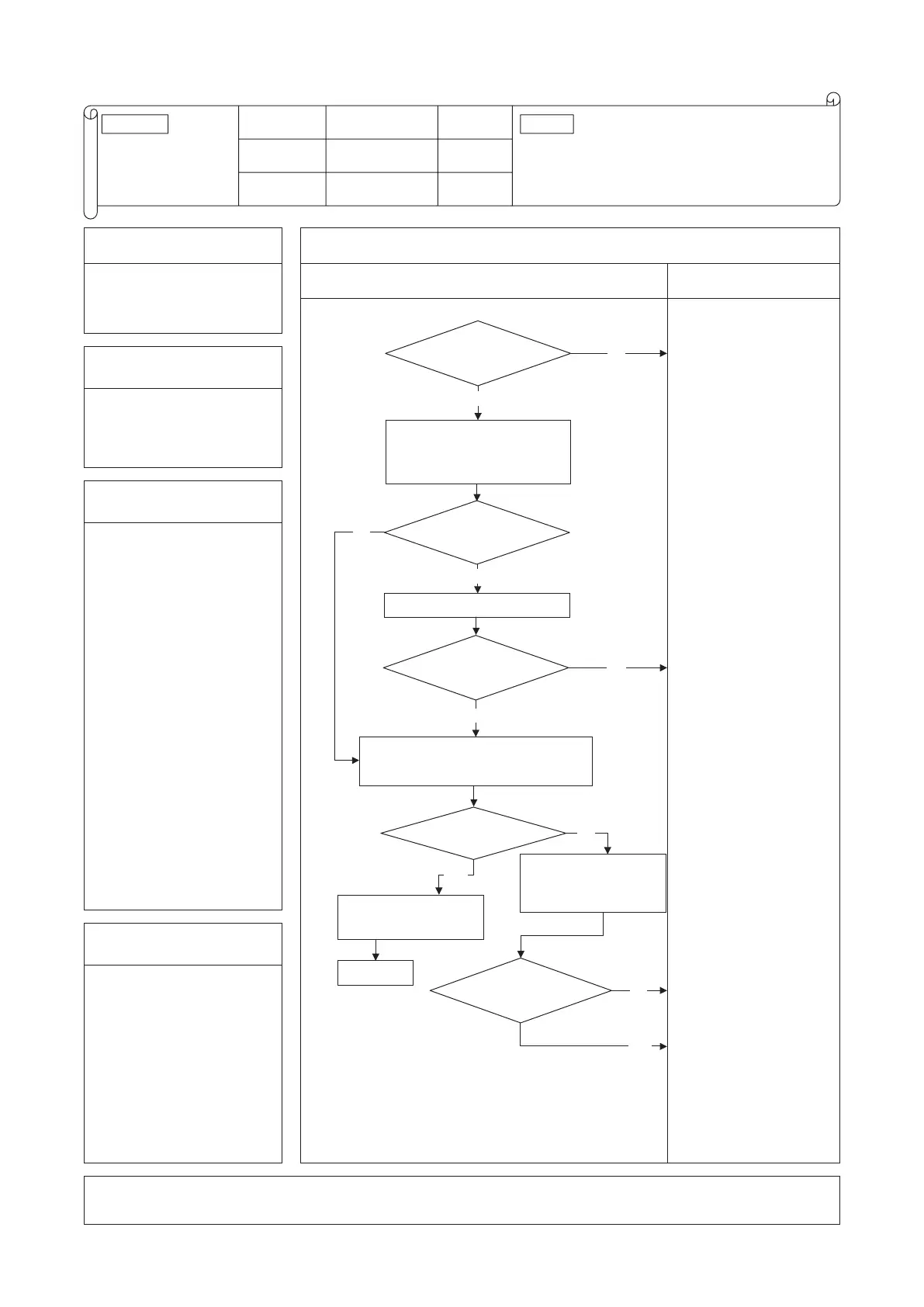

Diagnosis Countermeasure

NO

*

YES

Is the low

pressure sensor connection OK

(at PCB side)?

NO

Is the

insulation resistance more than 100MΩ

at DC500V?

Is the

pressure difference less than

0.2MPa?

Is the pressure

0MPa displayed on the remote

control?

NO

YES

Check the low pressure value during

following state from the remote control

➀ Compressor is stopping

➁ Compressor is operating

During

both ➀ and ➁ state low

pressure detected at around 0MPa

without any

fluctuation.

YES

Check the insulation resistance of pressure sensor.

YES

After connecting the gauge manifold on the low pressure

line, measure at the state ➀ above. Compare the result

with the value indicated on the remote control.

NO

NO

To checking of refrigerant

amount, refrigerant circuit,

etc.

YES

Connect the pressure sensor of

spare part to outdoor unit main

PCB in the condition open to

atmosphere.

To next page

Correct.

Replace low pressure

sensor.

Defective outdoor unit

main PCB

➞

Replace.

Replace low pressure

sensor.

2. Error detection method

Detected by low pressure drop

and suction superheat

3 .

Condition of error displayed

➀ When the low pressure sensor

detects 0.079MPa or lower

for 15 seconds continuously,

compressor stops and it

restarts automatically after

3-minute delay. And if this

anomaly occurs 5 times

within 60 minutes.

➁ 10 minutes after the

compressor starts, if the

low pressure sensor detects

0.15MPa or lower for 60

minutes continuously and

compressor suction superheat

is detected 30degC or higher

for 60 seconds continuously.

And if this anomaly occurs 5

times within 60 minutes.

➂ If low pressure sensor

detects 0.079MPa or lower

for 5 minutes continuously

(including the compressor

stop status).

4. Presumable cause

• Defective outdoor unit main

PCB

• Defective low pressure sensor

connector

• Defective low pressure sensor

• Defective suction pipe

temperature sensor connector

• Defective suction pipe

temperature sensor

Note: * Connect the gauge manifold to the service valve check joint during cooling, or connect it to the check joint at internal

piping of outdoor unit during heating.

Low pressure error (1/2)