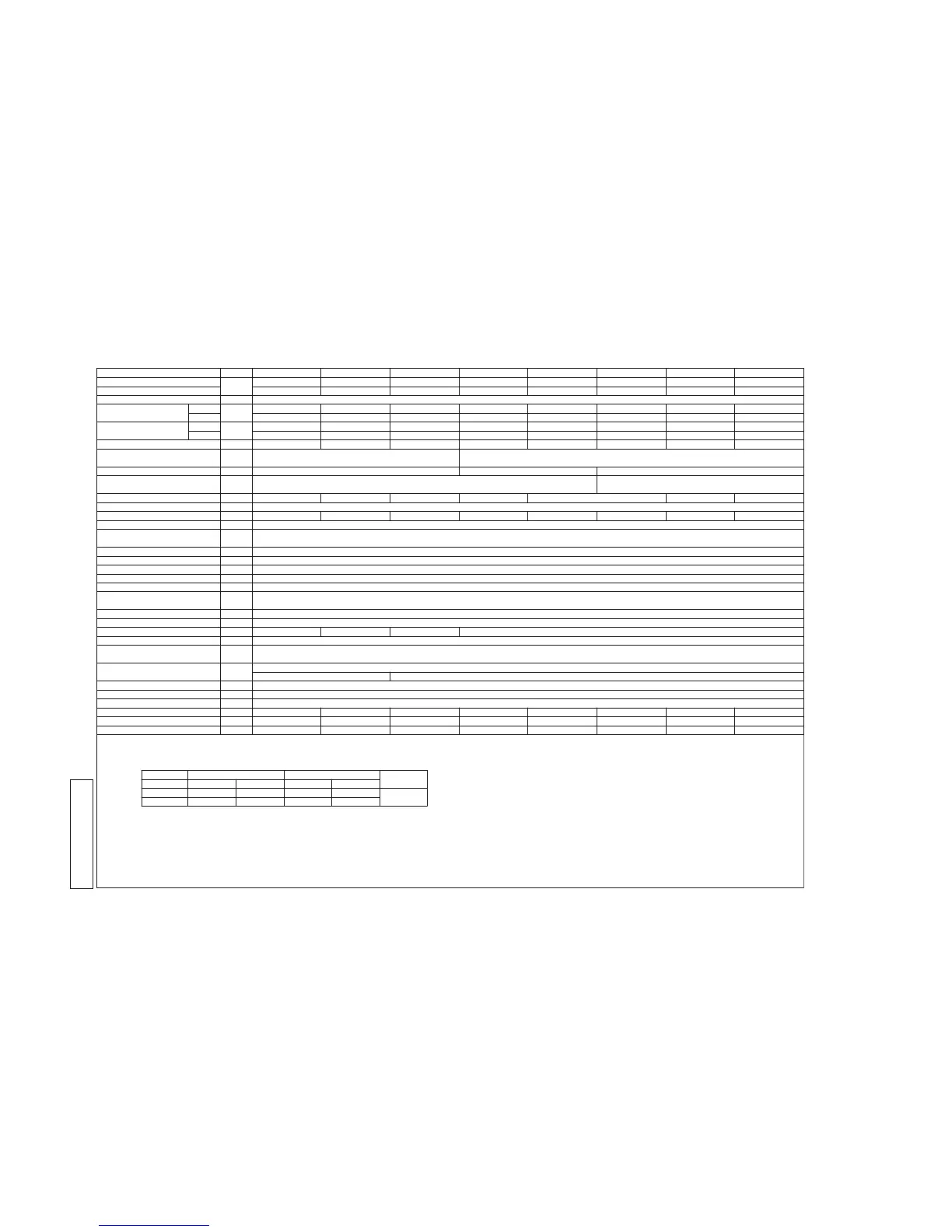

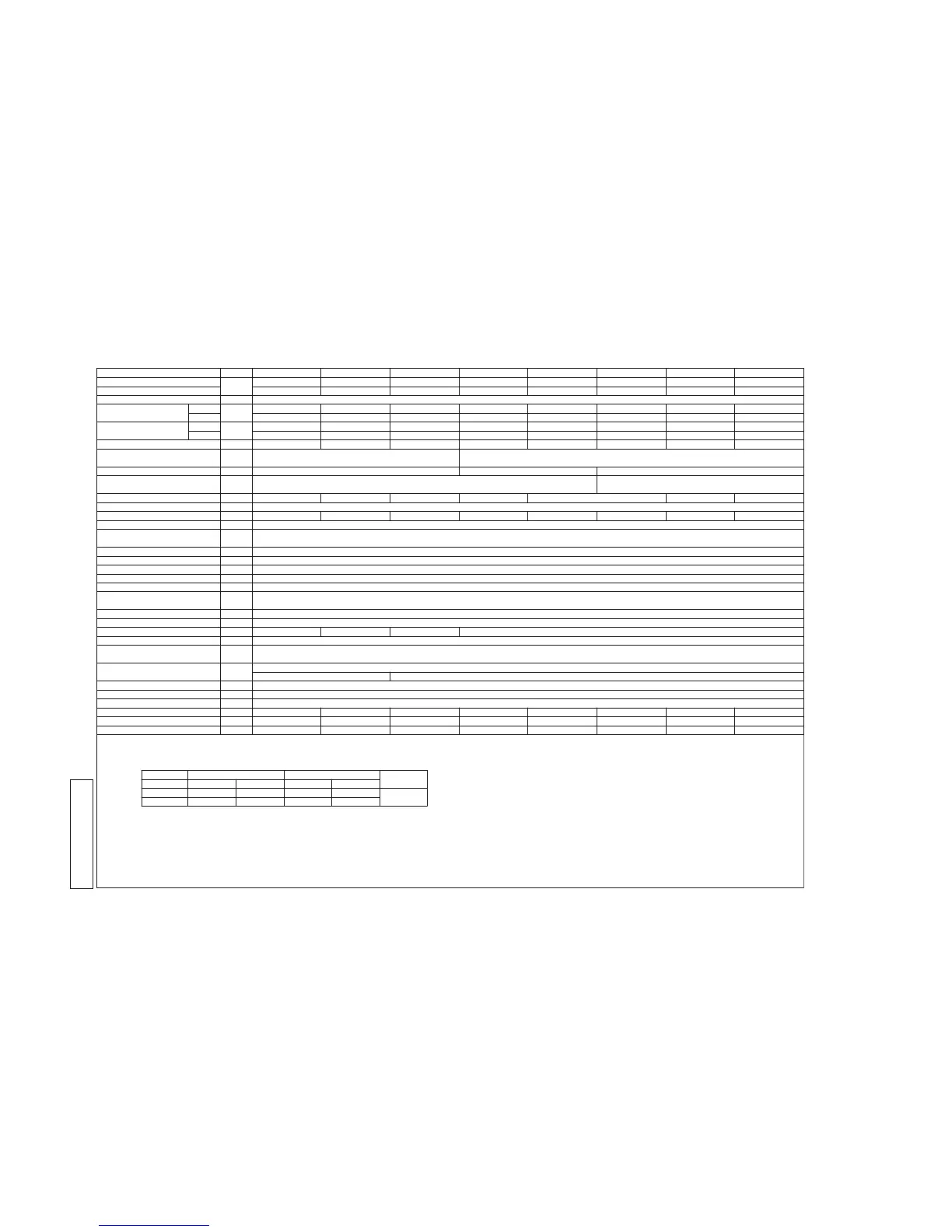

Notes (1) The data are measured at the following conditions.

Item

Indoor air temperature Outdoor air temperature

Standards

Adapted to RoHS directive

Operation DB WB DB WB

Cooling*1 19 ℃ 35 ℃ 24 ℃

ISO-T1

Heating*2 20 ℃ - 7 ℃ 6 ℃

ISO-T1 "UNITARY AIR-CONDITIONERS"

27 ℃

Models

Nominal cooling capacity*1

kW

Nominal heating capacity*2

Power source

Power consumption

Cool

kW

Heat

Running current

Cool

A

Heat

Sound Pressure Level dB(A)

Exterior dimensions

Height × Width × Depth

mm

Net weight kg

Refrigerant equipment

compressor type & Q'ty

Motor kW

Starting method

capacity control %

Crankcase heater W

Refrigerant equipment

Heat exchanger

Refrigerant control

Refrigerant

Quantity kg

Refrigerant oil l

Defrost control

Air handling equipment

fan type & Q'ty

Motor W

Starting method

Air flow(Standard) CMM

Shock & vibration absorber

safety equipment

Installation data

Refrigerant piping size

mm(in)

Connecting method

Drain

Insullation for piping

Accessories

Exterior dimensions

Electrical wiring

33.5 40.0 45.0 50.4 56.0 61.5 68.0

37.5 45.0 50.0 56.5 63.0 69.0 73.0

8.94 11.27 12.97 14.73 16.79 20.37 24.98

8.93 11.73 13.10 15.12 16.79 18.48 19.08

14.5/13.3

59/59 59.5/60 62.5/62.5 61.5/62 63/63.5 64.5/64 65/65

14.8/13.5 19.6/17.9 21.7/19.9 25.2/23.1 28.0/25.7 30.7/28.1 31.6/29.0

18.4/16.9 21.1/19.3 24.1/22.0 27.4/25.1 33.1/30.3 40.3/36.9

1690×1350×720 2048×1350×720

317 341 355

GTC5150NH48L×2 GTD5160NH48L×2

2.99×2 3.71×2 4.29×2 4.87×2 5.78×2 6.66×2 7.15×2

Direct line starting

19-130 15-114 13-112 11-100 10-113 11-110 10-108

33×2

Straight fin & inner grooved tubing

Electronic expansion valve

R410A

11.5

4.2(M-MA32R)

Microcomputer controlled De-Icer

Propeller fan × 2

386×2

Direct start

220/180 250/220 260/240 270/250

Compressor overheat protection / overcurrent protection / power transistor overheating

protection / abnormal high pressure protection

- - - - - - -

PCB003Z041 PCB003Z041 PCB003Z041 PCB003Z044 PCB003Z044 PCB003Z044 PCB003Z044

PCB003Z060 PCB003Z060 PCB003Z060 PCB003Z060 PCB003Z060 PCB003Z060 PCB003Z060

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard.

FDC335KXE6-K FDC400KXE6 FDC450KXE6 FDC504KXE6 FDC560KXE6 FDC560KXE6-K FDC615KXE6 FDC680KXE6

12-113

-

PCB003Z044

PCB003Z060

3 Phase 380-415V 50Hz/380V 60Hz

Rubber mount(for compressor)

Liquid line:φ12.7(1/2")

Gas line:φ28.58(11/8")

Gas line:Brazing / Liquid line:Flare

Hole for drain(φ20 × 6pcs , φ45 × 3pcs)

Necessary(both Liquid & Gas lines)

56.0

63.0

16.79

16.79

63/63.5

28.0/25.7

27.4/25.1

(3) Refrigerant piping size applicable to European installations are shown in parentheses.

Gas line:φ25.4(1")(φ28.58(11/8"))

Loading...

Loading...