ADJUSTMENT

AND

OPERATION

OF

CONTROL

UNIT

(FOR

Z-type

LIMI-STOP

motor)

rn

"1-2

POSITION"

select

switch

Needle

stop

position

can be

selected

between

"1

-POSITION"

and

"2—POSITION".

^mark

"2-POSITION"

_»

l_mark

"1-POSITION"

When the switch set at "1 POSITION", thread is trimmed in one turn of the sewing machine when the

pedal

is

kicked

back

by

heel.

I 2 I

Pedal

operation

The pedal operation and resultant motion (stitching, thread trimming and needle motion) are as

follows;

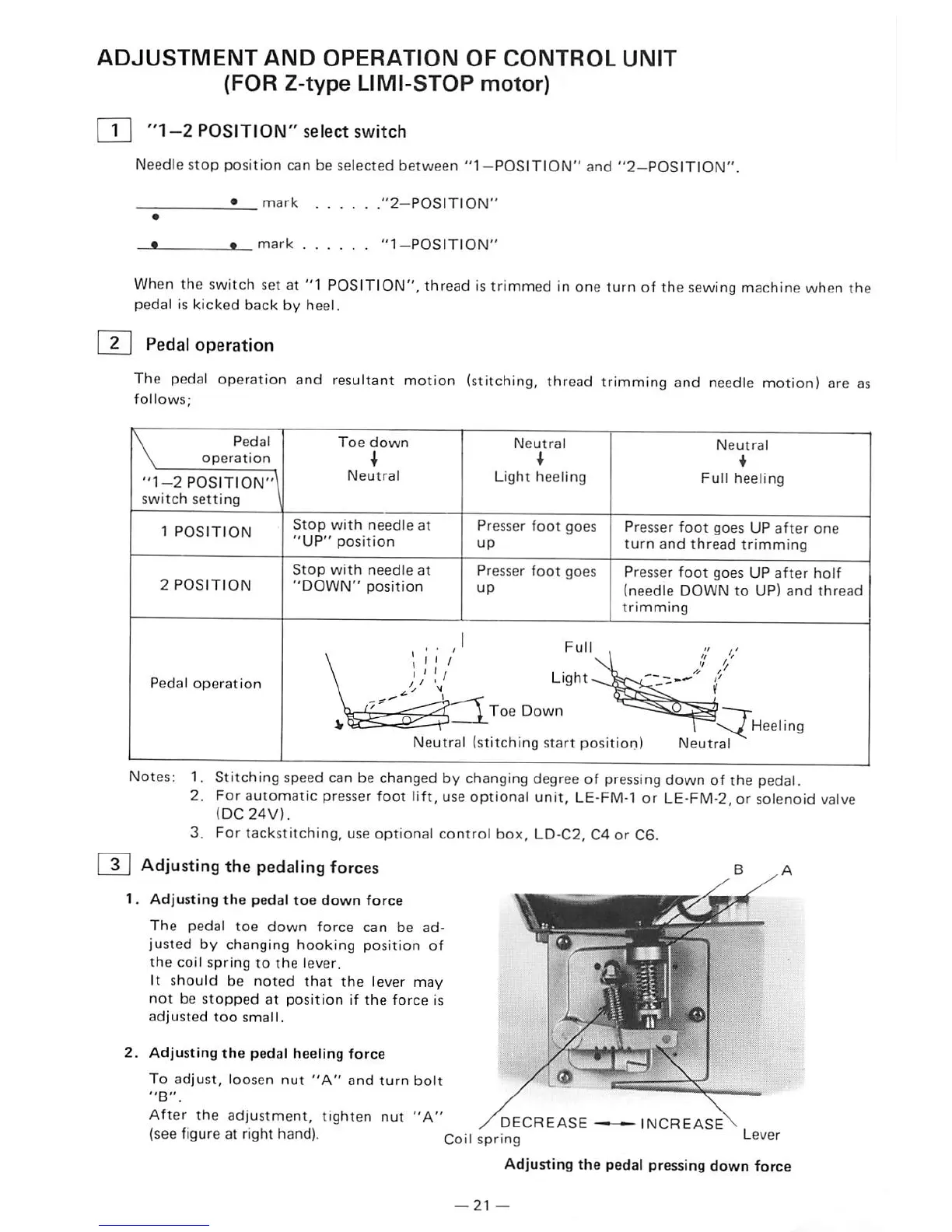

\

Pedal

\

operation

"1-2

POSITION"

switch

setting

1

POSITION

2

POSITION

Pedal

operation

Toe

down

I

Neutral

Stop

with

needle

at

"UP"

position

Stop

with

needle

at

"DOWN"

position

Neutral

4

Light

heeling

Neutral

Full

heeling

Presser foot goes Presser

foot

goes UP

after

one

up

turn

and

thread

trimming

Presser foot goes Presser foot goes UP

after

holf

up

(needle

DOWN

to

UP)

and

thread

trimming

1

Toe

Down

—T

'[

'Heeling

Neutral (stitching

start

position)

Neutral

Notes; 1. Stitching speed can be changed by changingdegree of pressingdown of the pedal.

2. For automatic presser foot lift, use optional unit,

LE-FM-1

or LE-FM-2,or solenoid valve

(DC

24V).

3.

For

tackstitching,

use

optional

control

box,

LD-C2,

04

or

06.

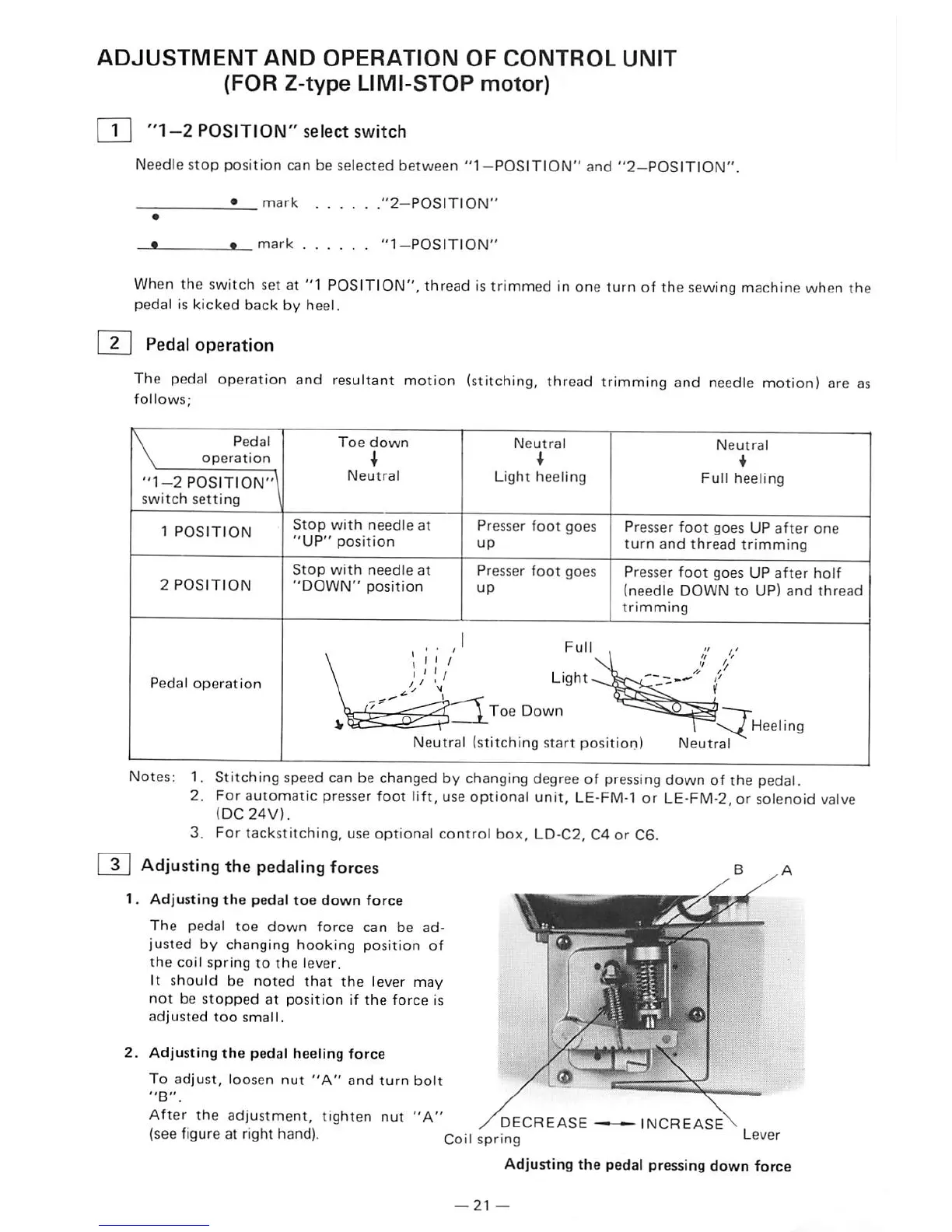

I 3 I

Adjusting

the

pedaling

forces B A

1.

Adjusting

the

pedal

toe

down

force

The

pedal

toe

down

force

can

be

ad-

justed

by

changing

hooking

position

of

the

coil

spring

to

the

lever,

It

should

be

noted

that

the

lever may

not

be

stopped

at

position

if

the

force

is

2.

Adjusting

the

pedal

heeling

force

To

adjust,

loosen

nut

"A"

and

turn

bolt

® ^

After

the

adjustment,

tighten

nut

"A"

/^^OREASE

-r

irMCnOAC^-

(see figure at right hand). Coil sorina Lever

/DECREASE

—^

INOREASE\ ,

Coilspring

Lever

Adjusting

the

pedal

pressing

down

force

—

21

-

Loading...

Loading...