I 20 I

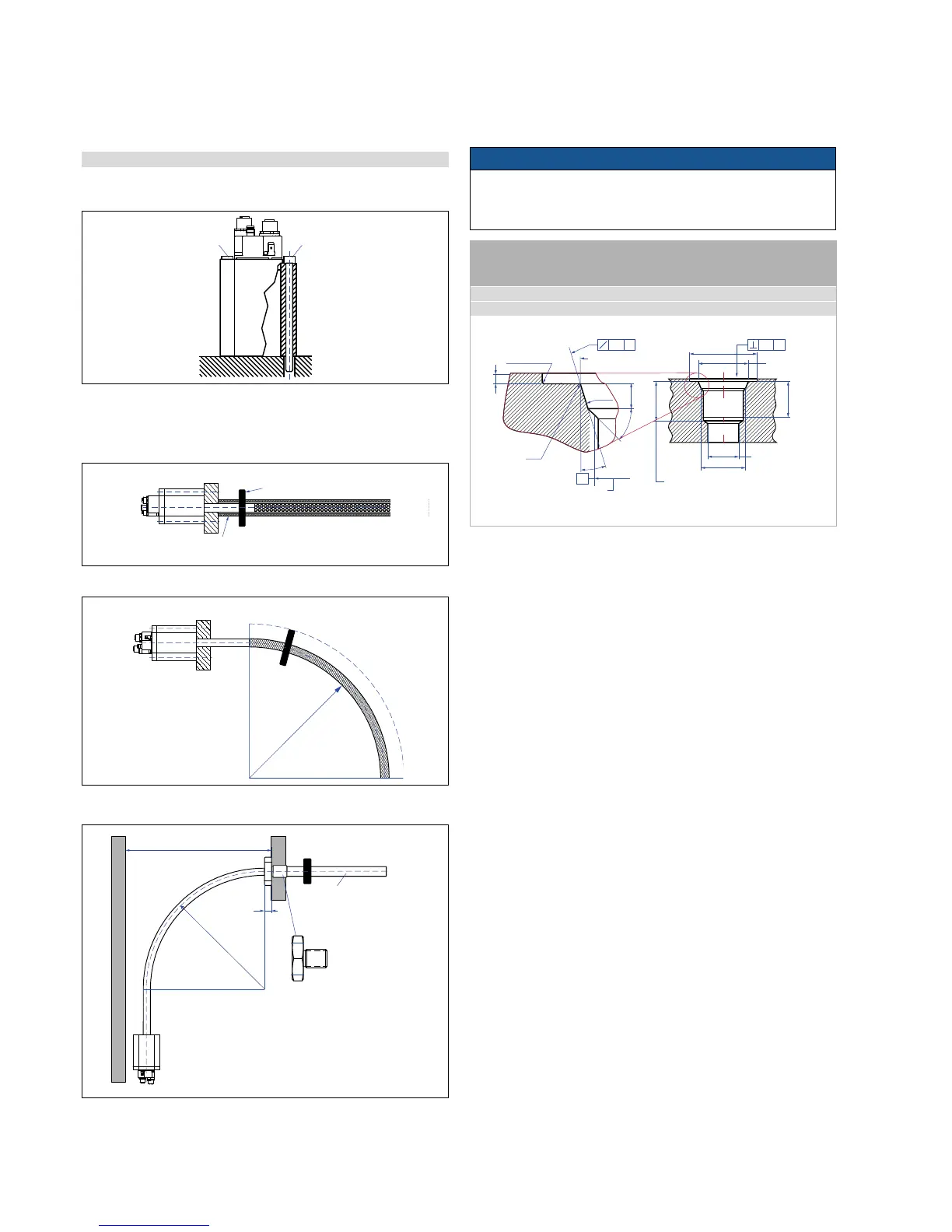

Fig. 43: Threaded flange M18×1.5 based on DIN ISO 6149-1

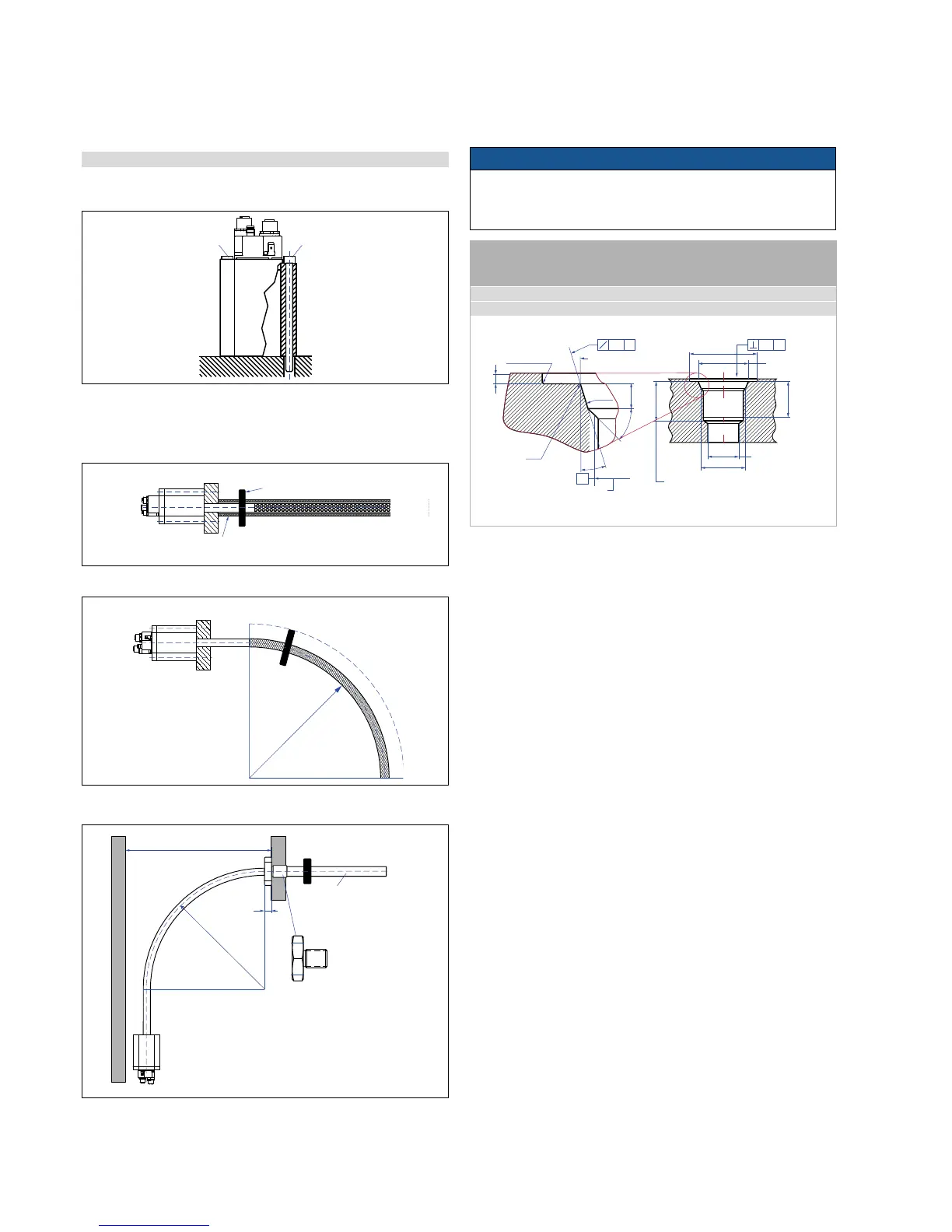

Fig. 39: Mounting screw M4×59

Fig. 40: Linear measurement

Fig. 41: Minimum bending radius

Fig. 42: Mounting example for distances

4.5.2 Installation of RF

Mounting of sensor electronics housing requires the use of

2 non-magnetizable screws M4×59.

NOTICE

A flexible sensor requires supports or anchoring to maintain proper

alignment between sensor rod and the magnet, otherwise the

sensor output signal can be interfered or lost.

Curvilinear measurements

Long sensors require a support tube (inner diameter of 9.4 mm

(0.37 in.)) of non-magnetizable material, straight or bent to the desired

For easy installation the sensor is supplied with a hex 46 flange (ac-

cessory) bored for above mounting screws.

Information about the mounting of the optinal accessories see:

• optional profile product brief 551 442

• optional rod with flange product brief 551 770

Thread

(d

1

×P)

d

2

d

3

d

4

d

5

L

1

L

2

L

3

L

4

Z°

M18×1.5 55 mm 13 mm 24.5 mm 19.8 mm 2.4 mm 28.5 mm 2 mm 26 mm 15°

3/4x16 See Appendix B

This dimension applies

when tap drill cannot

pass through entire boss

Thread (d

1

×P)

(Reference size)

Applies at Ød

4

A

R 0.4 max.

L

3

L

1

45° ±5°

Ra 3.2

Ød

5

Ra 3.2

Ød

2

Ra 0.2

Ra 0.1

Pitch diameter

Z°

L

2

L

4

A

0.2 A0.2 A

Ød

3

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

> 250

(> 9.84)

Internal hexagon

M4×59

Internal hexagon

M4×59

500 (19.69) recommended

≥ 300 (≥ 11.8) minimum

Magnet

10

(0.39)

AF46

Flange M18×1.5 or 3/4“-16

Stainless steel 1.4305 for

rod 12.7 (0.5) AD

Part no. 402 704 (M18)

Part no. 402 641 (3/4“-16)

Customized support tube

required, inside Ø 9.4 mm

non-magnetic

e.g. Ø 12.7 × 1.65 mm

> 250

(> 9.84)

Position magnet

Non-magnetizable support tube, inner-Ø 9.4 (0.37)

Loading...

Loading...