2205Q2JE-HO-S6-N_2020.01.

Chapter 5 Maintenance and Inspection

SCV-series Screw Compressor 5.4 Disassembly and Inspection

5-29

c) The whole thrust bearing will be removed helped by the surface tension of the oil on the side face.

If you have failed to remove the whole bearing at once, put the components in the order of the

removal.

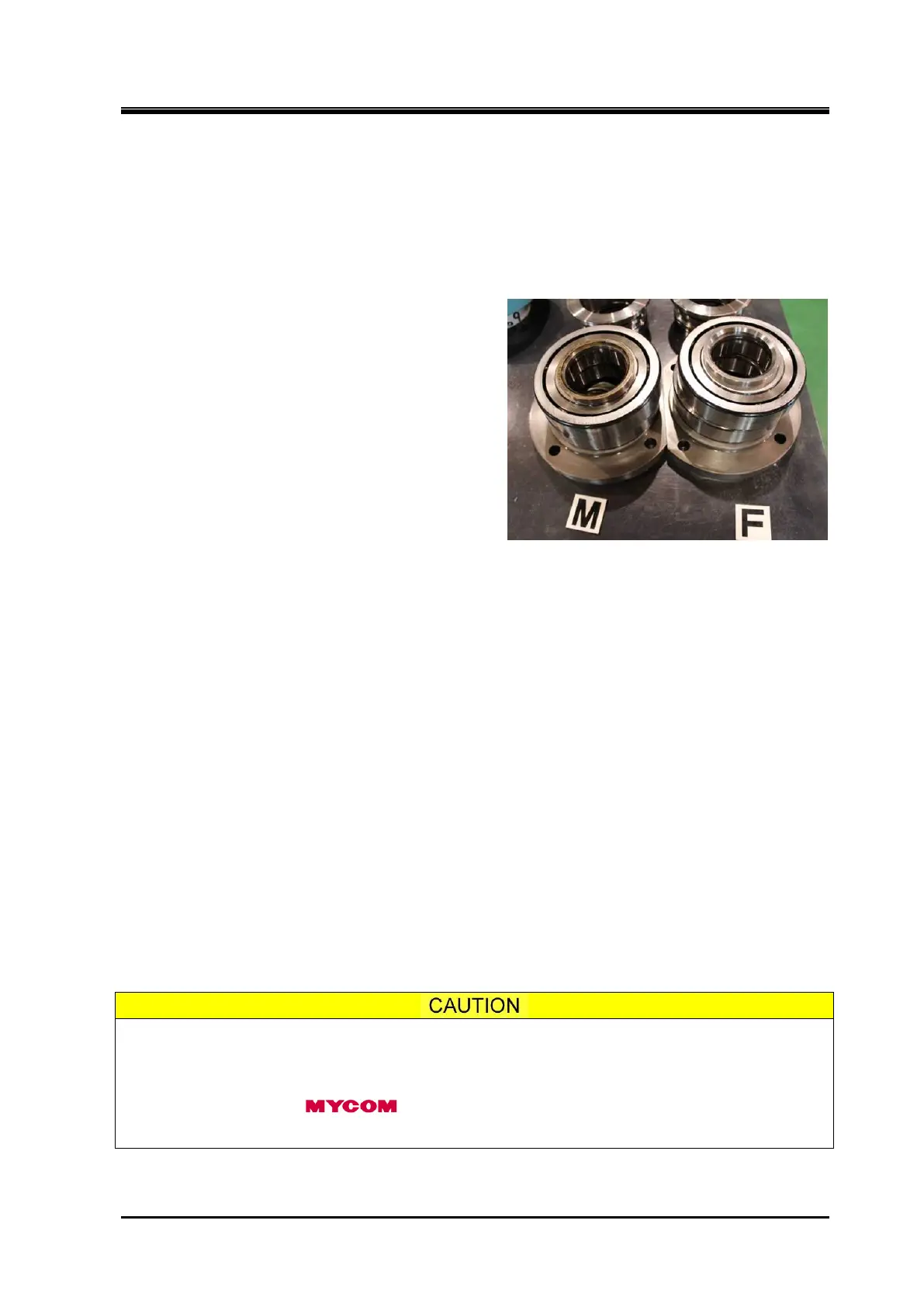

d) Inside the thrust bearing is an alignment spacer [42] for the inner race on the rotor shaft side.

Also, 160V** models and 200V** models are used the thrust bearing outer race spacer [41] on the

bearing head side. Each spacer has a marking to identify where to set, i.e., the M rotor side has a

stamped marking of "M", and the F rotor side has a stamped marking of "F".

Neatly arrange the parts removed, i.e., the

thrust bearing gland, thr

bearing, thrust bearing alignment spacer,

thrust bearing outer race spacer

the M rotor and F rotor as shown in right picture.

You must be very careful because if an

assembly error is made to result in a wrong

combination of parts after failing to neatly

arranging and separating the parts, it can lead

to performance degradation and/or dragging

accident due to overheating caused by excess

tightness, for example.

5.4.8.2 Inspection

a) The thrust bearing is normal if the bearing balls are found fully glossy after the thrust bearing has

been fully washed and cleaned. It is abnormal if the ball surface is tarnished or has some streaky

pattern.

b) Support the inner race with your hand and rotate the outer race. If you feel abnormal vibration on the

hand, the rolling contact surface of the inner or outer race or some balls may be in an abnormal

condition. So, carefully check the conditions. You could feel some irregular click even with a small

amount of foreign matter that has entered during the removal process. In such a case, it should

return to the normal condition when high pressure air is used to blow out the foreign matters after

washing and cleaning the unit. If the bearing is determined to be defective, it must be replaced with

new ones.

c) If the inner race and outer race can be easily separated, the wear is considered excessive. If so, you

cannot reuse the bearing.

d) After washing the bearing, you should be able to hear a clattering sound when the bearing is rotated

y hand. Such a sound is due to the motion of the ball within the backlash or play, or the gap between

the retainer and the ball. Such a sound will not be heard if the bearing is held horizontal and turned.

If some lubricating oil is applied after washing the bearing, the sound should not be heard when the

bearing is turned. If you can still hear the sound, you should check further details.

e) If the compressor has been operated for more than 20,000 hours without replacing the thrust bearing,

it is recommended to replace the bearing with a new one for safely continuing the operation until the

next overhaul, even if no abnormality is found in the above described inspection.

As the bearing used for the compressor is a specially designed combined-type bearing,

the accuracy and material are different from normal ones of the same part number that

may be found in the catalogue of a bearing manufacturer.

Be sure to use only

genuine parts for replacement. Otherwise, it will not

be covered by the warranty.

Loading...

Loading...