30 Installing the System Piping

3.3.1 Make-up Water Connection

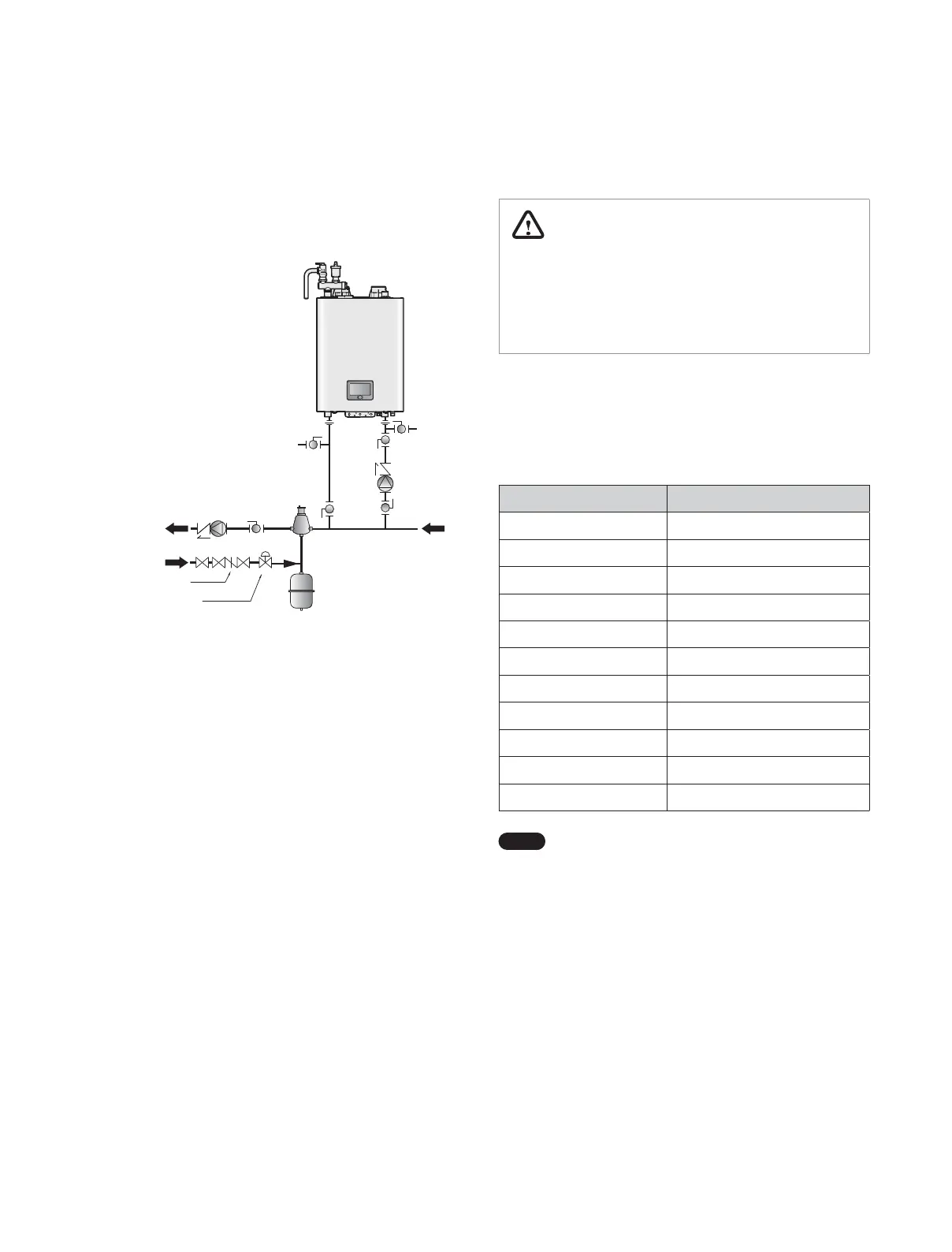

An external make-up water connection is required. The illustration

below shows an example of an external water supply connected to

the system piping.

Pressure Reducing Valve

Backflow Preventer

Air Separator

Pump

Expansion Tank

To System

Make-up Water

From

System

3.4 Testing the Water System

WARNING

Ensure that the boiler is full of water before firing the burner.

Operating the unit without completely filling it will damage

the boiler. Such damage is not covered by the warranty, and

may result in property damage, severe personal injury, or

death.

Perform a leak test after installing the boiler’s water system to

make sure that the system has been installed properly. Follow the

instructions below to perform a leak test on the water system.

1. Fill the system only after ensuring that the water chemistry

meets the requirements.

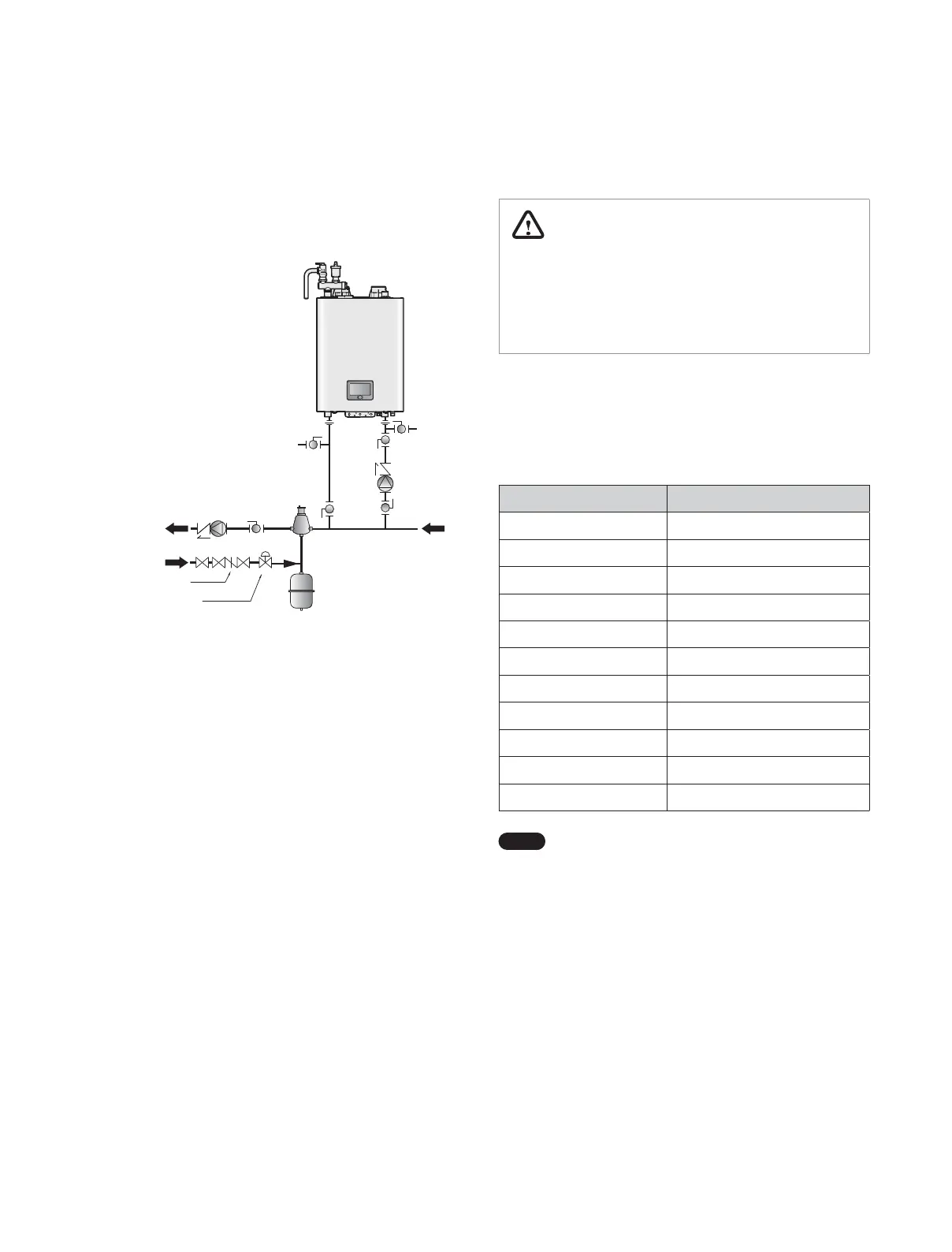

Contaminant Maximum Allowable Level

Total Hardness Up to 200 mg/l (12 grains/gallon)

Aluminum 0.05 to 0.2 mg/l

Chloride Up to 250 mg/l

Copper Up to 1.0 mg/l

Iron Up to 0.3 mg/l

Manganese Up to 0.05 mg/l

pH 6.5 to 8.5

Sulfate Up to 205 mg/l

Total Dissolved Solids (TDS) Up to 500 mg/l

Zinc Up to 5 mg/l

Chlorine Up to 4 mg/l

Note

Proper maintenance of the boiler is required when

water quality does not meet standards. Damage caused

by poor water quality is not covered under warranty.

The table above shows the maximum contaminant

levels allowed. If you suspect that your water is

contaminated in any way, discontinue the use of water

heater and contact an authorized technician or licensed

professional.

Loading...

Loading...