SECTION 5 – MAINTENANCE SCHEDULE AND SERVICE PROCEDURES

Service Procedures (cont.)

ENGINE OIL AND FILTER (cont.)

10. Lubricate new oil filter gasket with clean en gin e oil.

CAUTION: To prevent engine damage, install the correct oil filter

for the engine application.

11. Ins tall new oil filter.

• Standard oil filter (long)

• Front drive/steering axle oil filter (sho rter)

CAUTION: To prevent engine damage, do not overtighten filter.

12. Hand tighten filter 2/3 to 1 full turn after gasket first contacts

oil filter header.

CAUTION: To prevent engine damage, do not overfill with oil.

13. Add engine oil with the correct oil viscosity and formulation.

API CJ-4 oil is recommended but CI-4 is allowable. Use of

CI-4 oils will reduce DPF cleaning interval, see Maintenance

Schedule (page 59). Add oil through the engine oil fill tube.

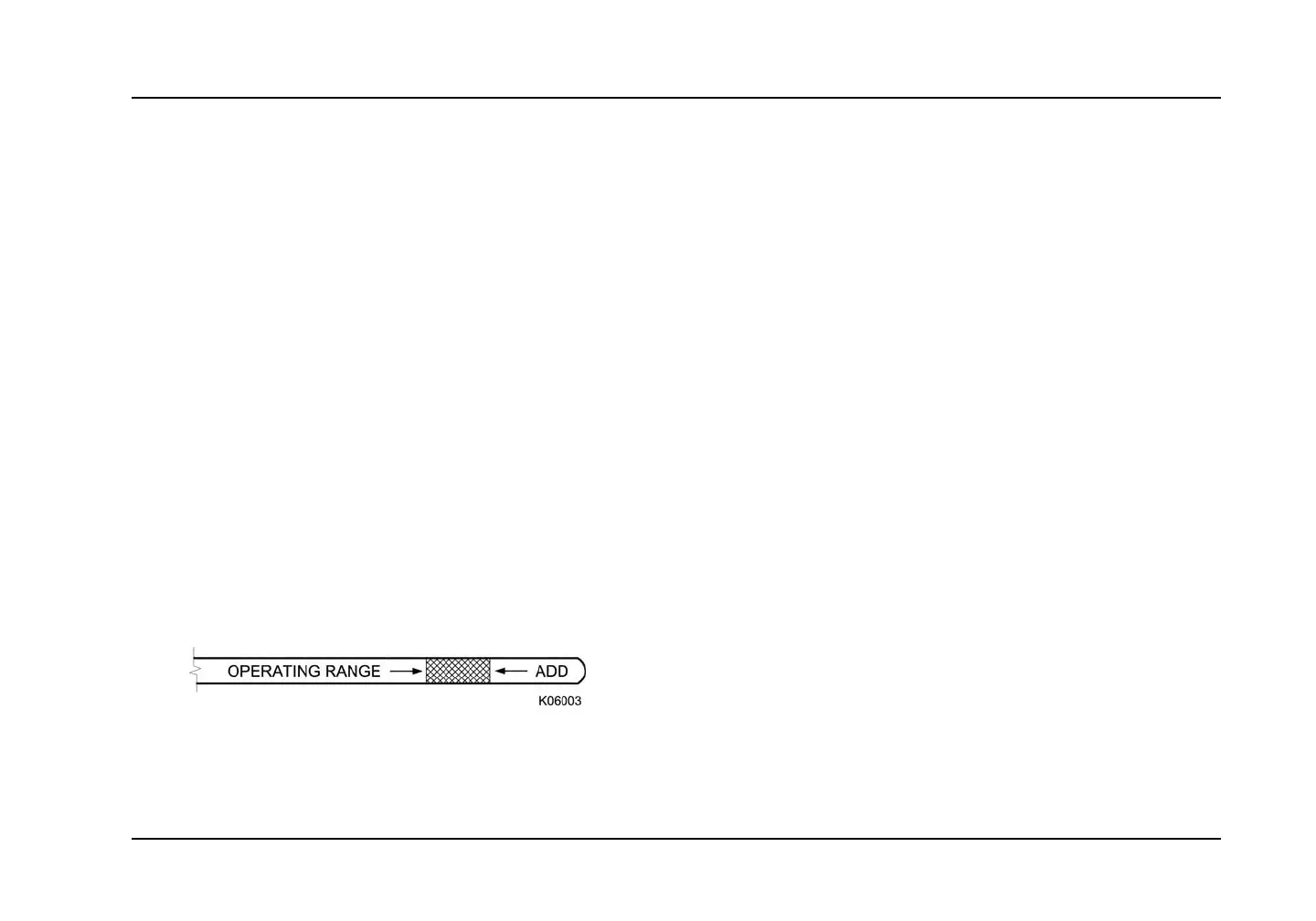

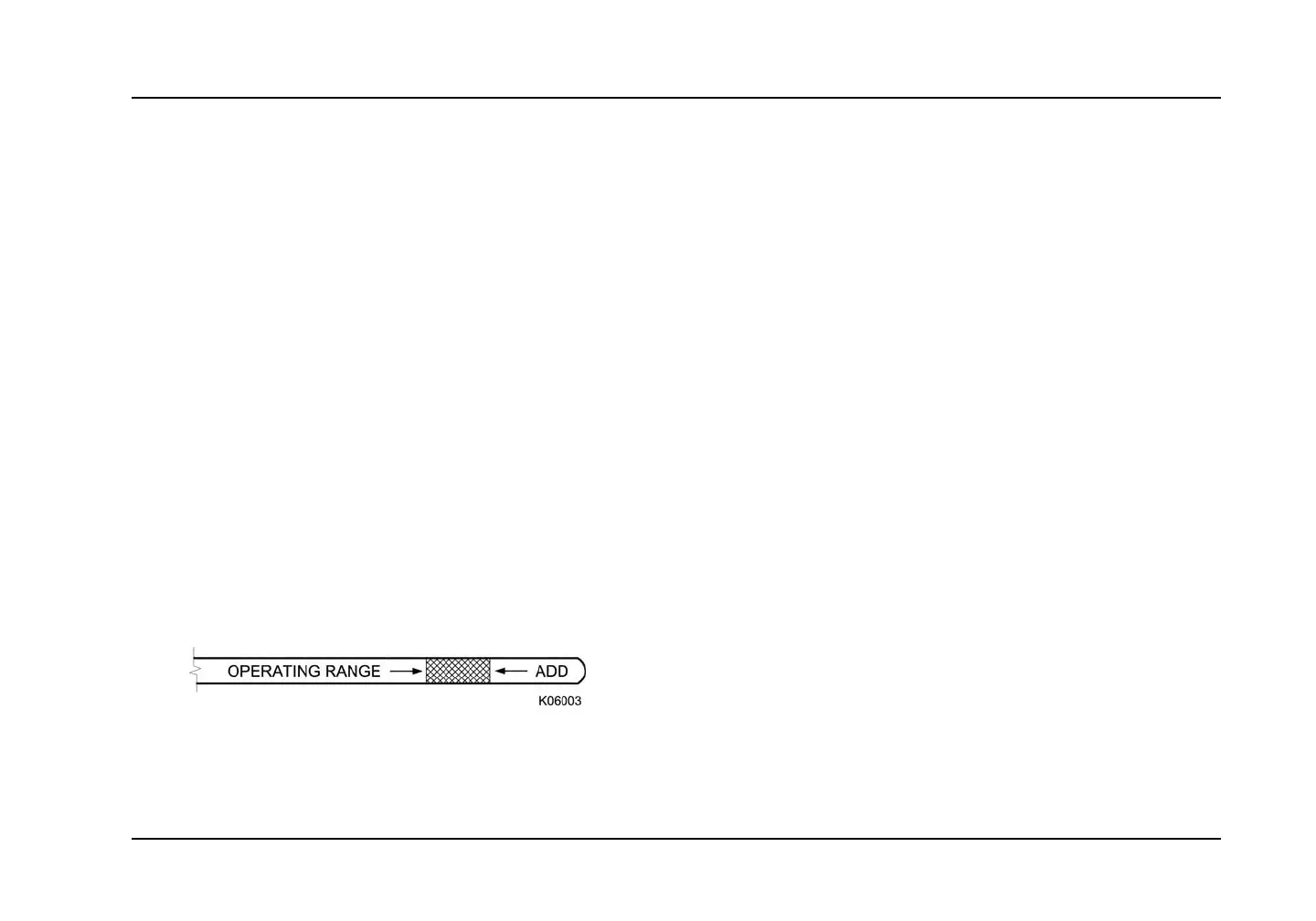

Figure 32 Oil level gauge (typical)

14. Check oil level gauge. Oil level must be within the

crosshatched operating range.

15. Start engine and run at low idle.

16. Check reading on oil pressure gauge.

• Minimum lube oil pressure is 214 kPa (31 psi) minimum

@ 700 rpm.

• If there is no gauge reading, shut engine down

immediately. Check for oil filter leaks.

• Let engine run until operating temperature is reached.

Check for leaks.

17. Shut down engine for 15 minutes.

CAUTION: To prevent engine damage, do not overfill with oil.

18. Recheck oil level and add oil to bring oil level within the upper

half of the crosshatched operating range on oil level gauge.

CENTRIFUGE FILTER (IF EQUIPPED)

Service Interval (based upon fuel consumption and specific

engine application):

Form No. 1172040R1

Printed in the United States of America Page 73

Loading...

Loading...