MEASUREMENTS

Measurements referring to the vertical plane:

Considering the vertical plane "C1" : The vertical action

towards the top of shaft "A" on the micrometer is dominant.

In the plane "C1" the axis "A" is higher than axis "B”

( 0.9 – 0.1 ) / 2 = - 0.05 mm

In the vertical plane "C2", the vertical action towards the

top of shaft "B" on the micrometer is greater.

In the plane "C2" the axis "B" is higher than axis "A"

( 0.134 – 0.102 ) / 2 = 0.16 mm

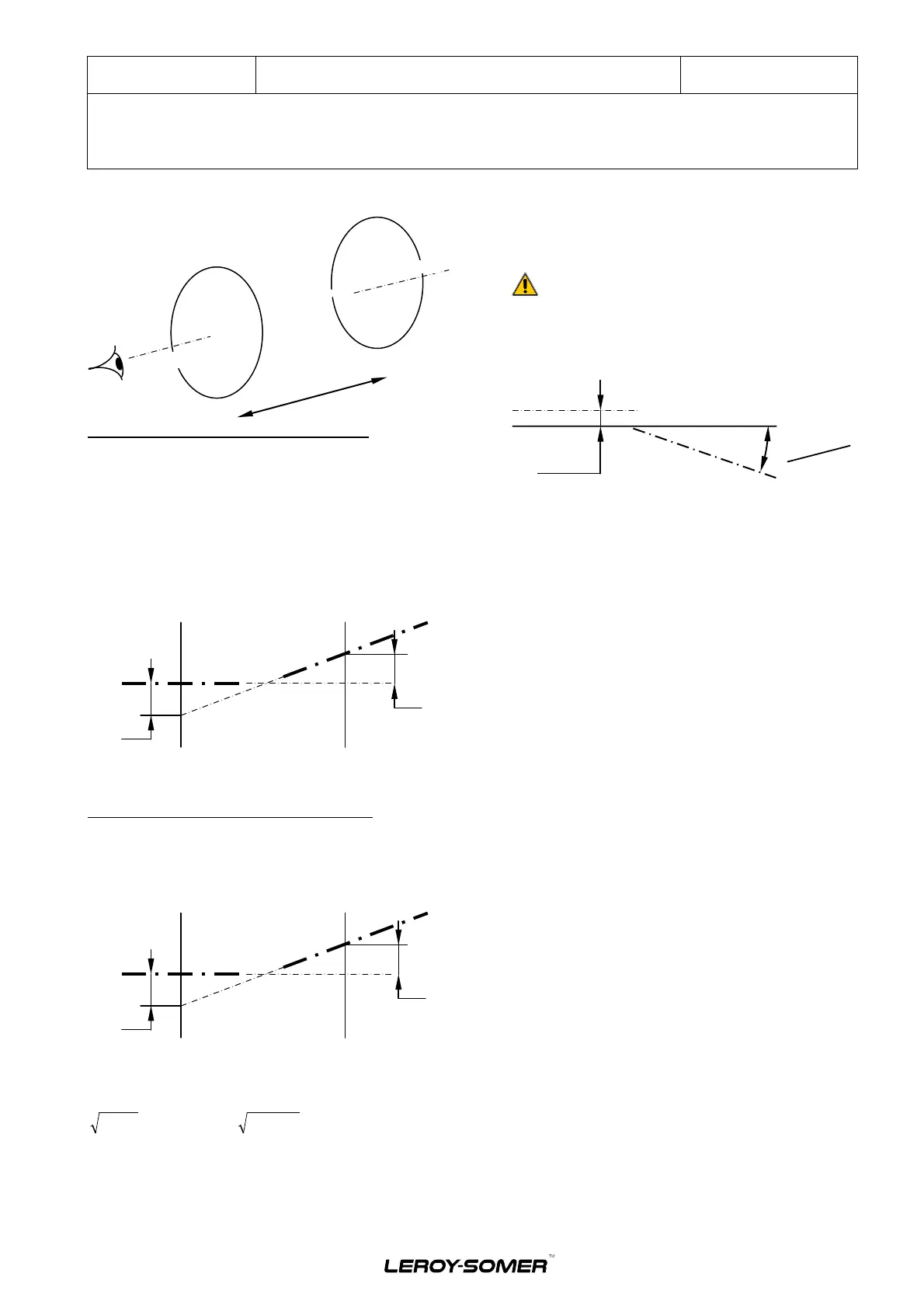

The respective position of the axes is as follows:

Regarding the vertical plane the angular alignment error is:

( 0.16 + 0.05 ) *100 / 400 = 0.0525 mm/100mm (not

acceptable)

Measurements referring to the horizontal axis:

In the plane "C1" the axis "B" is further to the right than "A”

( 0.104 – 0.86 ) / 2 = 0.09 mm

In the plane "C2" the axis "B" is further to the left than "A”

( 0.70 - 1.64 ) / 2 = - 0.47 mm

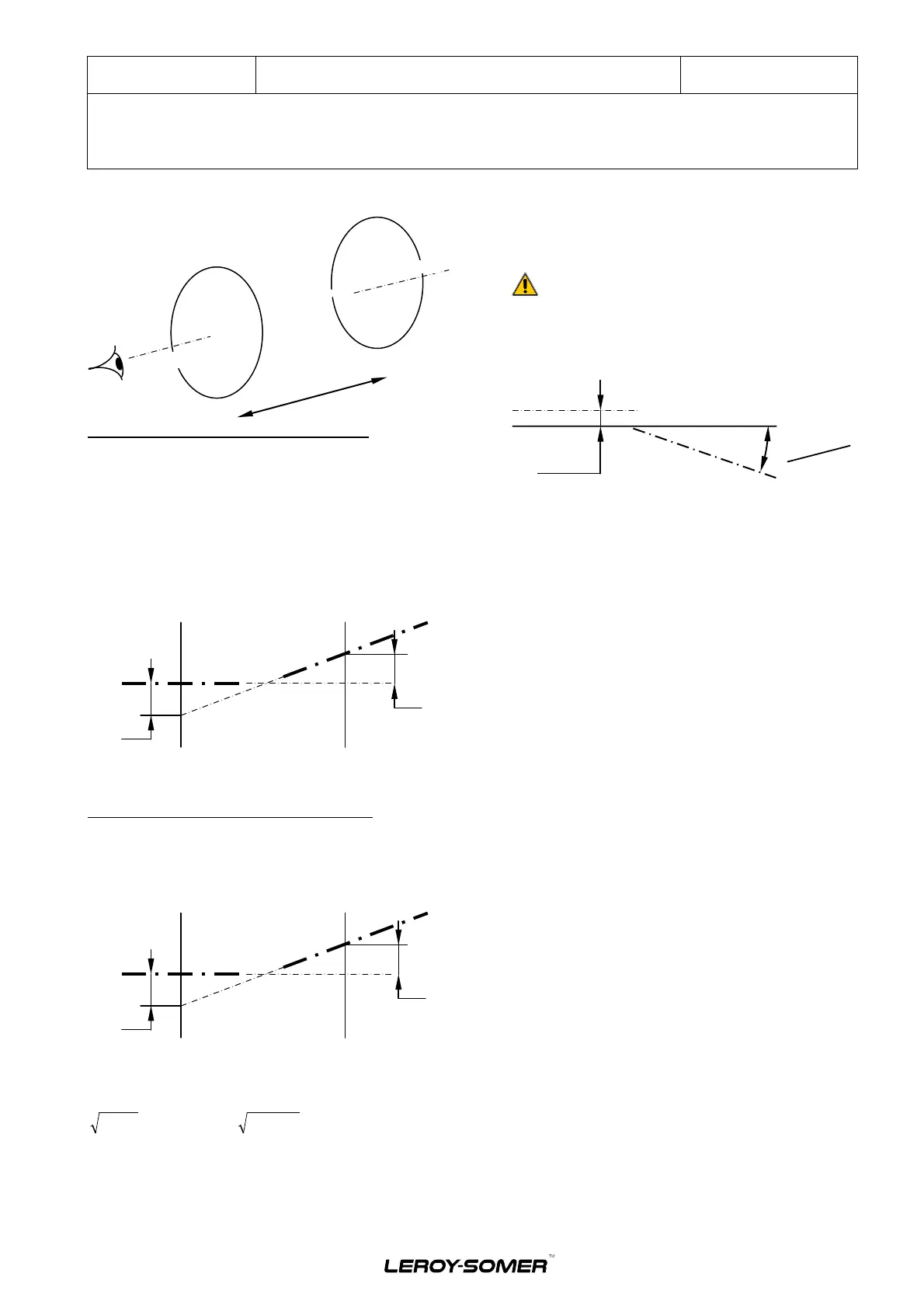

The representation of the shafts is as follows:

Regarding the horizontal plane the angular error is:

( 0.47 + 0.09 ) *100/ 400 = 0.14 mm/100mm (not

acceptable)

In the both planes the parallelism error is:

or

(not

acceptable)

3.3.2 Two bearings machine alignment (flanged)

3.3.2.1 Machines without axial end play (standard)

The alignment must take the tolerances of the coupling into

account.

CAUTION:

A MISALIGNMENT EVEN IF ACCEPTABLE BY THE

COUPLING MUST NOT CREATE STRESSES LEVEL

NOT ACCEPTABLE BY THE BEARING

Shafts alignment limits to follow:

0.08 mm

parallelism error

To check the alignment, there are different methods: the

"double concentricity" method is described in the

"alignment procedure" chapter 3.3.1.6.

Electric Power Generation

Installation and maintenance

5654 en - 2017.10 / a

LSA 52.2 MHV

Industrial Range Alternators - 4 pole

13

Loading...

Loading...