14

Chapter4.–Installation

GeneralRequirements

• Under normal conditions, this appliance will not produce an exhaust ue temperature in excess of 149°F (65°C) and schedule 40

PVC pipe may be used as the vent material. If the water heater set temperature is 160°F (70°C) or higher and there is a return line

to the water heater from either a recirculation pump, schedule 40 CPVC must be used.

• Make sure the vent system is gas tight and will not leak.

• Support the vent pipe with hangers at regular intervals as specied by these instructions or the instructions of the vent manufacturer.

• Do not common vent or connect more than one appliance to this venting system.

• The total vent length including horizontal & vertical vent runs should be no less than 3' (0.9m).

• Do not store hazardous or ammable substances near the vent termination and check that the termination is not blocked in any way.

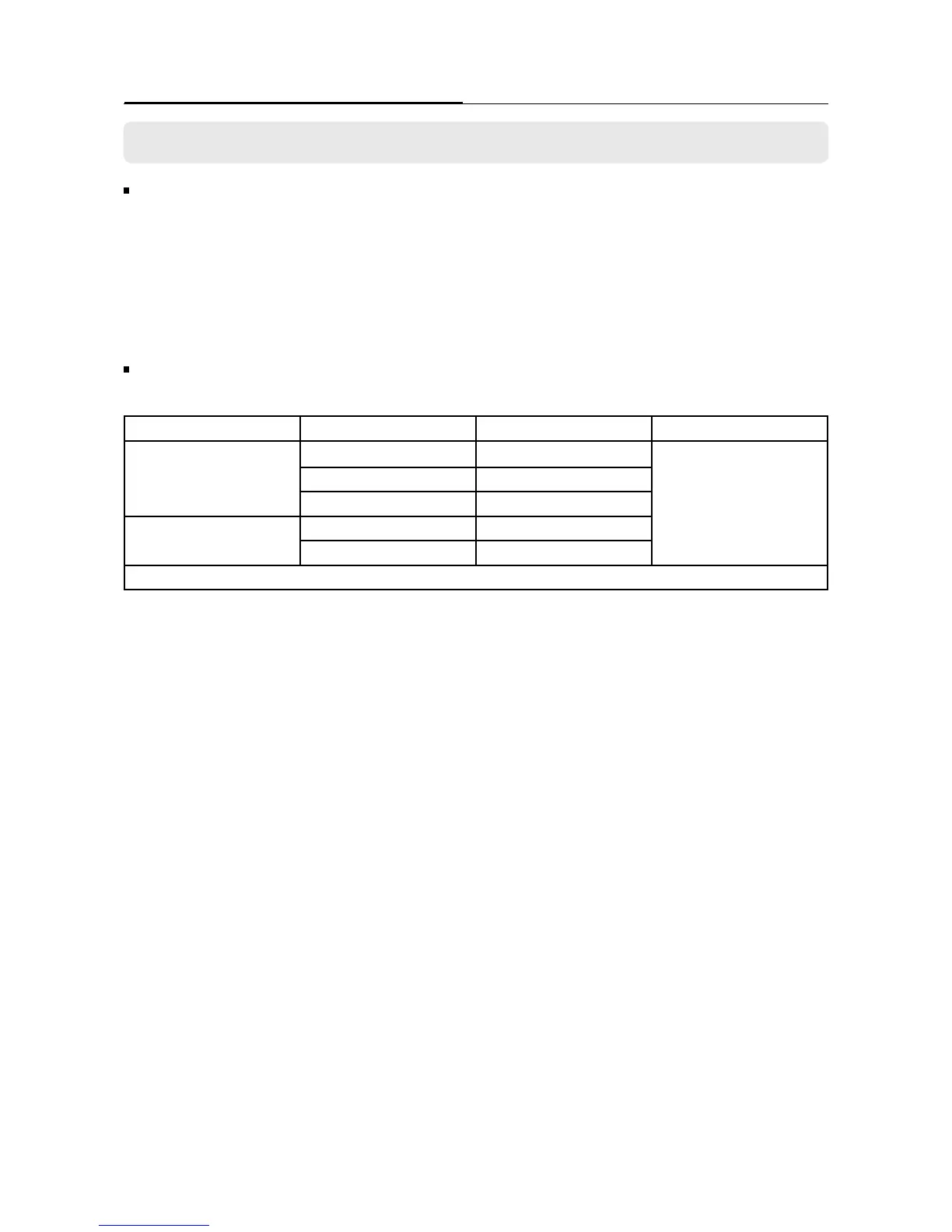

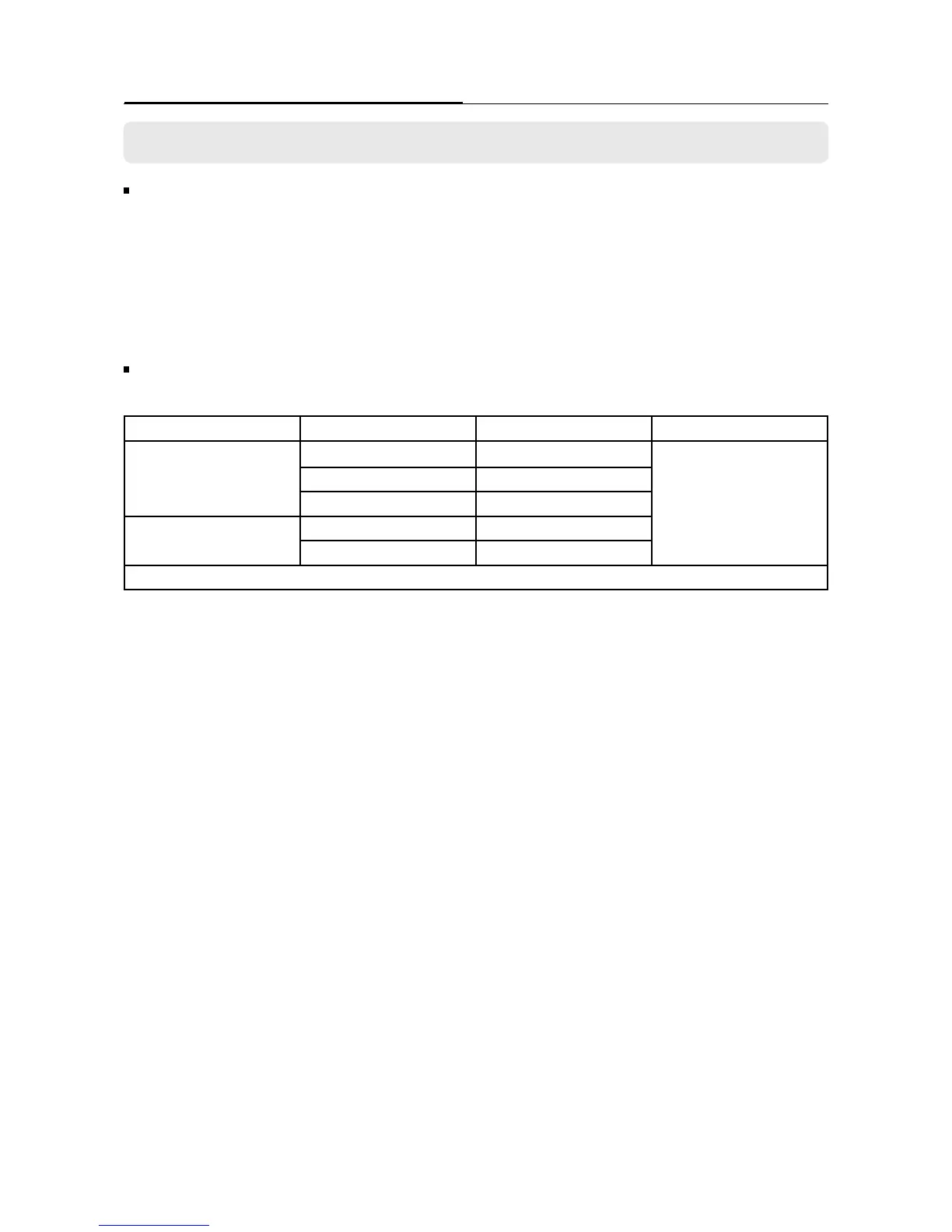

VentingWithPVCorCPVC

This appliance can be vented with non cellular core plastic pipe materials as specied in the below table.

Vent installations in Canada which utilize plastic vent systems must comply with ULC S636.

Item Material United States Canada

Exhaust Vent /Air Intake

Schedule 40 PVC ANSI/ASTM D1785

ULC S636 Certied

Materials Only

PVC-DWV ANSI/ASTM D2665

Schedule 40 CPVC ANSI/ASTM F441

Pipe Cement/Primer

PVC ANSI/ASTM D2564

CPVC ANSI/ASTM F493

Note: Do Not Use Cellular Foam Core Pipe

• Use only solid PVC or CPVC schedule 40 pipe. Cellular foam core piping is not allowed.

• In Canada, plastic vent systems must be certied to ULC S636. The components of the certied vent system must not be interchanged

with other vent systems or unlisted pipe/ttings.

• In Canada, specied primers and glues of the ULC S636 certied vent system must be from a single system manufacturer and not

intermixed with other system manufacturer’s vent system parts.

• PVC or CPVC pipe has been approved for use on this appliance with zero clearance to combustibles.

• Follow all general venting guidelines as outlined on this page.

• The pipe shall be installed so that the rst 3' (0.9m) of pipe from the appliance ue outlet is readily accessible for visual inspection.

• When preparing and assembling the pipe, follow instructions as provided by the pipe manufacturer. In general, the following

practices must be observed:

* Squarely cut all pieces of pipe.

* Remove all burrs and debris from joints and ttings.

* All joints must be properly cleaned, primed, and cemented. Use only cement and primer approved for use with the pipe

material as outlined in the above table.

• All piping must be fully supported. Use pipe hangers at a minimum of 3' (0.9m) intervals. Do not use the water heater to support

the vent piping.

• A bird screen must be installed on the vent terminations to prevent debris or animals from entering the piping.

Vent Pipe Installation

4-2. Vent Pipe Installation (IndoorInstallationOnly)

Loading...

Loading...