7

Serial Communications Connection Procedure

7. Serial Communications Connection Procedure

This section describes the procedures for connecting PLC to Driver using serial

communications.

The explanations of procedures for setting up PLC and Driver given in this document are

based on the factory default settings.

For the initialization, refer to Section 8. Initialization Method.

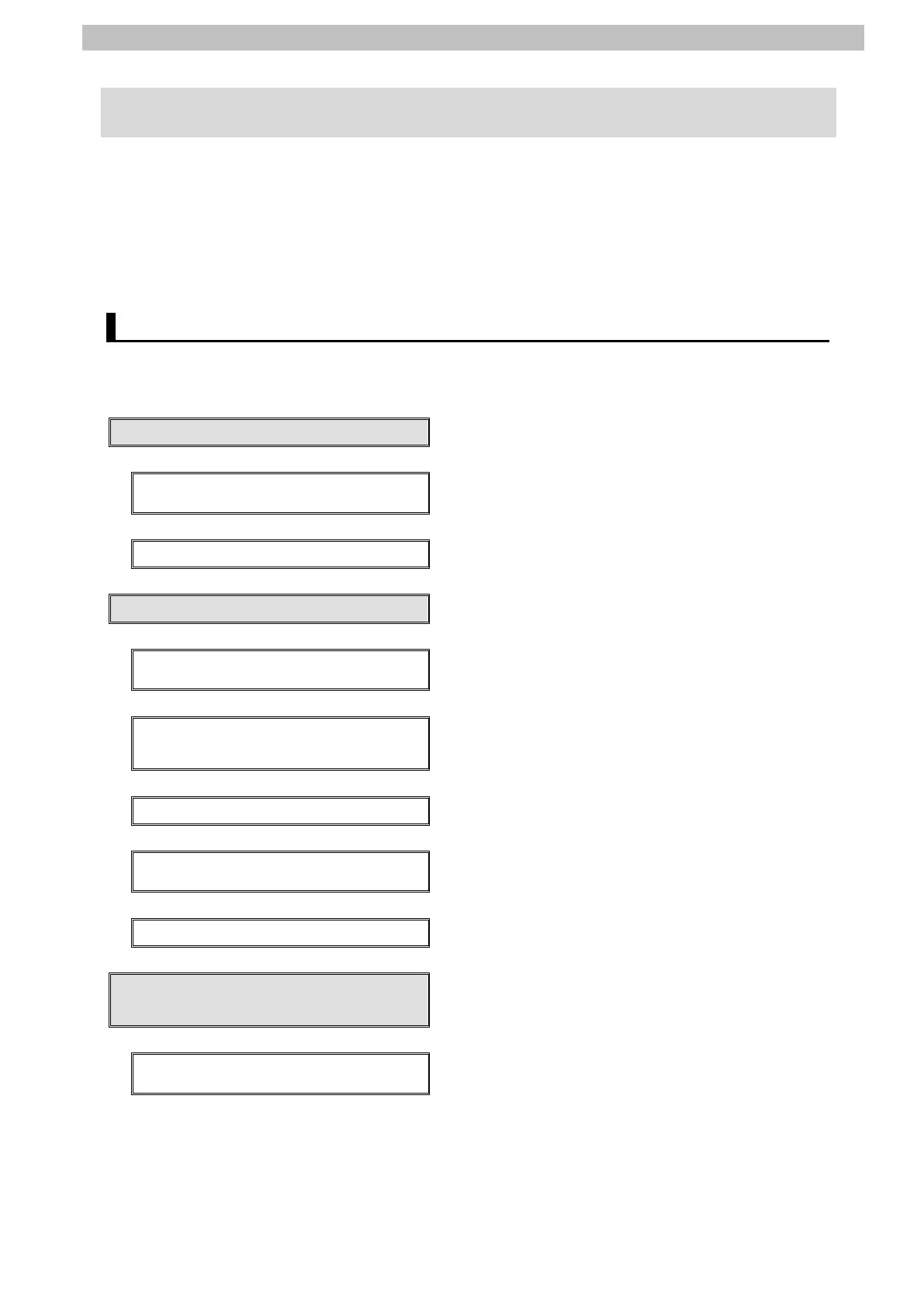

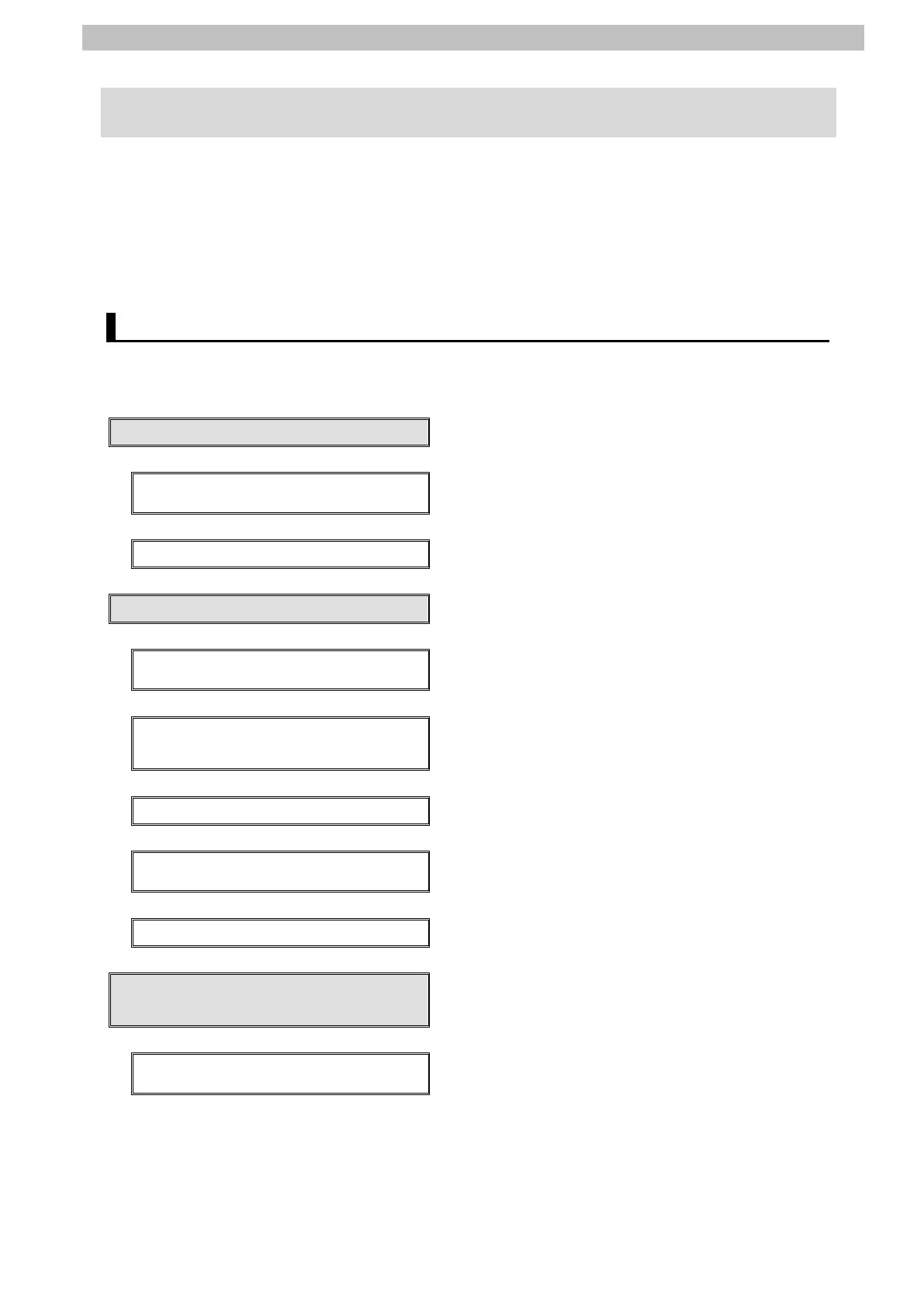

7.1. Work Flow

Take the following steps to connect PLC to Driver using serial communications and to send /

receive messages.

7.2. Oriental Motor Driver Setup

Set up Oriental Motor Driver.

↓

7.2.1. Hardware Settings

Set the hardware switches on Driver and connect

the cables.

↓

7.2.2. Parameter Settings

Set the parameters for Driver.

↓

↓

7.3.1. Hardware Settings

Set the hardware switches on Serial

Communications Unit and connect the cables.

↓

7.3.2. Opening the Project File and

Connecting Online with PLC

Start CX-Programmer, open the project file, and

connect online with PLC.

↓

7.3.3. Creating the I/O Table

Create the I/O table for PLC.

↓

7.3.4. Parameter Settings

Set the parameters for Serial Communications

Unit.

↓

7.3.5. Transferring the Project Data

Transfer the project data to PLC.

↓

7.4. Serial Communication Status

Start the send/receive processing and confirm that

serial communications is performed normally.

↓

7.4.1. Checking the Receive Data

Check that the correct data is written to the I/O

memory of PLC using CX-Programmer.

Loading...

Loading...