General Information

INTRODUCTION

This manual deals with specific mechanical and elec-

trical information needed by engine mechanics for

troubleshooting, servicing, repairing, or overhauling

the engine.

Use the table of contents for a quick reference to the

separate engine system sections.

Use the separate Parts Catalogs available at the

dealer level, for parts identification and for establish-

ing their proper location on assemblies.

The

TROUBLESHOOTlNG

GUlDE

provides

a

quick

reference for locating and correcting engine trouble.

The illustrations and procedures presented in each

section apply to the engines listed on the cover. The

flywheel end of the engine is the front end,

so

right

and left sides are determined by viewing the engine

from the front.

The disassembly section contains major overhaul

procedures for step by step removal, disassembly,

inspection, repair and assembly of the engine

components.

If a major repair or an overhaul is necessary, a compe-

tent mechanic should either do the job or supervise

and check the work of the mechanic assigned to do

the job to ensure that all dimensions, clearances and

torque values are within the specified tolerances.

The wiring diagram shows how the electrical compo-

nents are interconnected.

A parts catalog (available at the dealer level) contains

detailed exploded views of each assembly and the

individual piece part nurnbersand their proper names

for ordering replacement parts.

Use only Genuine Onan replacement parts to ensure

quality and the best possible repair and overhaul

results. When ordering parts, always use

the

com-

plete Model and Spec number

in

addition to the Serial

number shown on the nameplate.

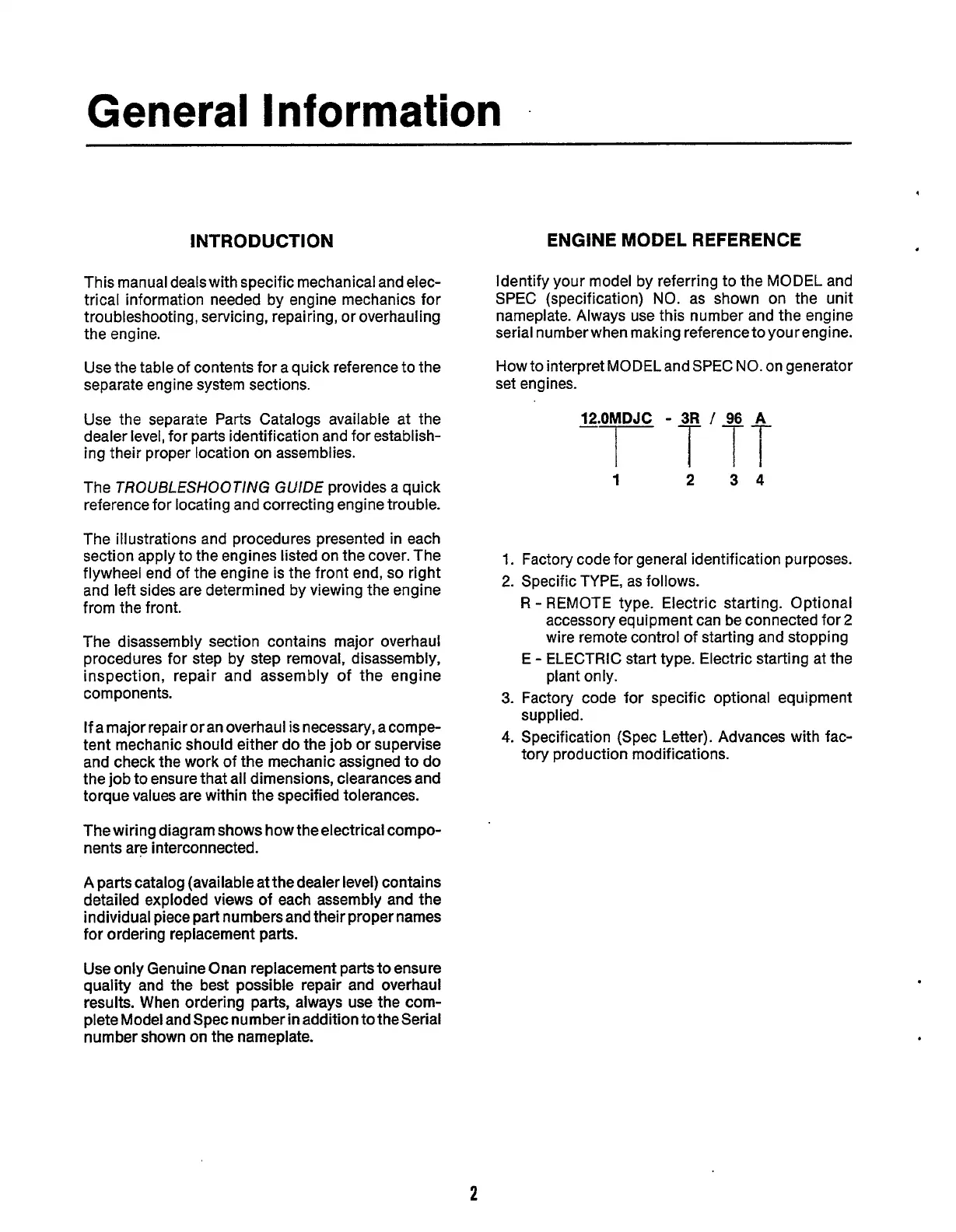

ENGINE MODEL REFERENCE

Identify your model by referring to the MODEL and

SPEC (specification)

NO.

as shown on the unit

nameplate. Always use this number and the engine

serial numberwhen making reference toyour engine.

How to interpret MODEL and SPEC

NO.

on generator

set engines.

1.

2.

3.

4.

12.OiDJC

-

f

/

7

f

1

2

34

Factory code for general identification purposes.

Specific TYPE, as follows.

R

-

REMOTE type. Electric starting. Optional

accessory equipment can be connected for

2

wire remote control

of

starting and stopping

E

-

ELECTRIC start type. Electric starting at

the

plant only.

Factory code for specific optional equipment

supplied.

Specification (Spec Letter). Advances with fac-

tory production modifications.

2

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...