series. It is to use the existing piping by adjusting the refrigerant

gas volume.

Please do correct piping installation referring to the above table.

Attention

- Please do not decrease the gas piping size. (It causes the

breakdown of the compressor).

- The equivalent piping length and the cooling and heating capacity

change rate are same as the standard piping specification.

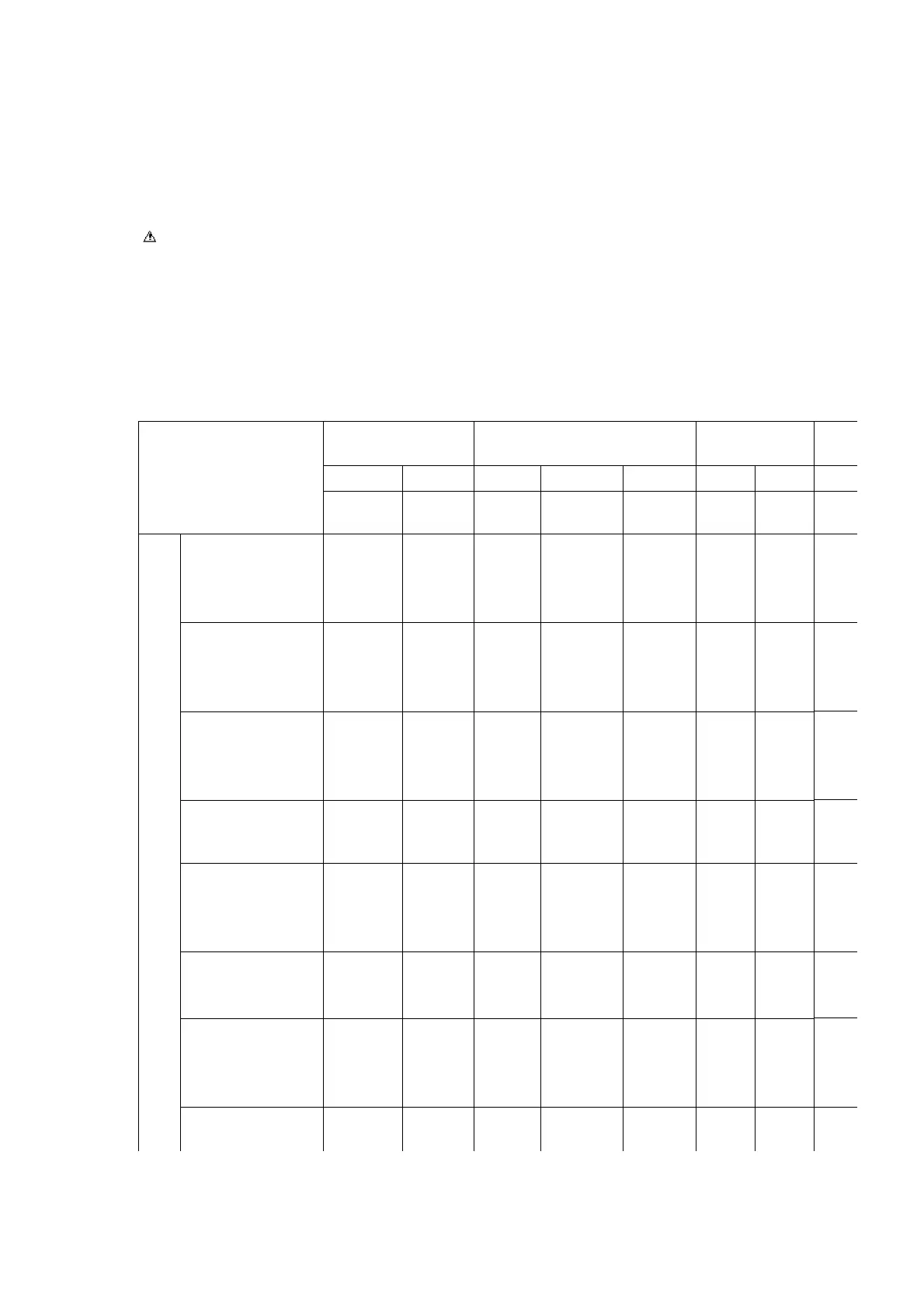

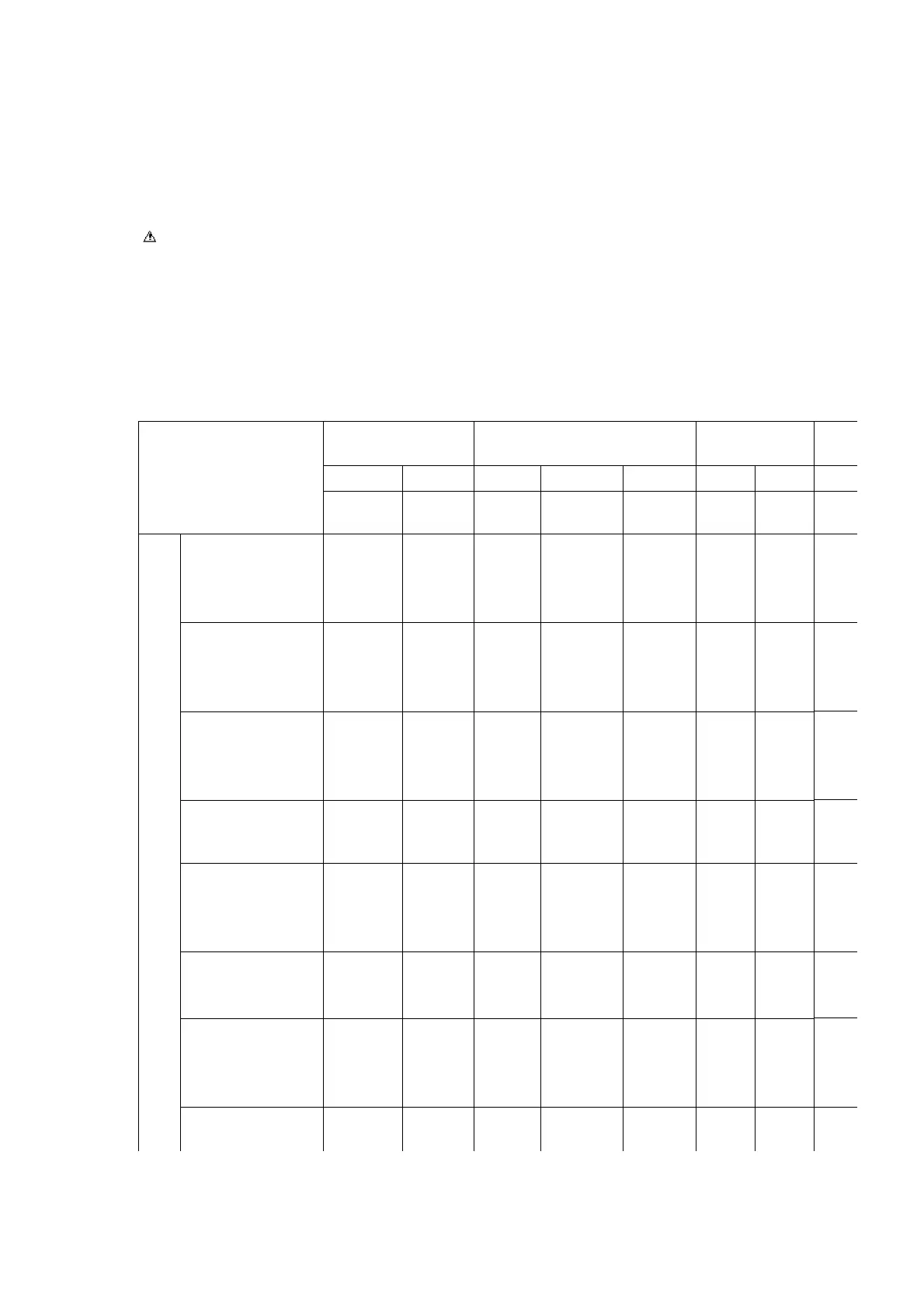

11. OPERATING CHARACTERISTIC

Model Main Power Source Compressor Motor

Indoor Unit

Fan Motor

Voltage

Frequency

S.C. R.C. (A) IPT (kW) R.C. IPT

(V) (Hz) (A) Cool/Heat Cool/

Heat

(A) (kW) (A)

CS-A24BB4P 220 50 49 10.6 2.31 0.40 0.08

CU-C24BBP5 230 50 51 10.2 2.31 0.40 0.08

240 50 52 9.8 2.31 0.40 0.08

CS-A28BB4P 220 50 50 11.35 2.49 0.45 0.09

C CU-C28BBP5 230 50 52 11.05 2.49 0.45 0.09

O

240 50 54 10.75 2.49 0.45 0.09

O CS-A28BB4P 380 50 28 4.08 2.49 0.45 0.09

L CU-C28BBP8 400 50 29 4.03 2.49 0.45 0.09

I

415 50 30 3.98 2.49 0.45 0.09

N CS-A28BB4P

G CU-C28BBP6 220 60 70 14.35 3.00 0.45 0.09

O CS-A34BB4P 220 50 94 15.3 3.23 0.70 0.15

N CU-C34BBP5 230 50 99 15.4 3.23 0.70 0.15

L

240 50 103 15.5 3.23 0.70 0.15

Y CS-A34BB4P 380 50 39 5.13 2.93 0.70 0.15

CU-C34BBP8 400 50 41 5.13 2.93 0.70 0.15

M 415 50 42 5.13 2.93 0.70 0.15

O CS-A34BB4P

D CU-C34BBP7 220 60 86 10.30 3.73 0.70 0.15

E

L CS-A43BB4P 380 50 58 6.63 3.82 0.90 0.20

CU-C43BBP8 400 50 58 6.63 3.82 0.90 0.20

70

Loading...

Loading...