12

* AUTOJET 60/50, AUTOJET 70/50, AUTOMAX 80/48, AUTOMAX 120/60

If the problem persists despite the recommended corrective actions, contact the Customer Assistance Service.

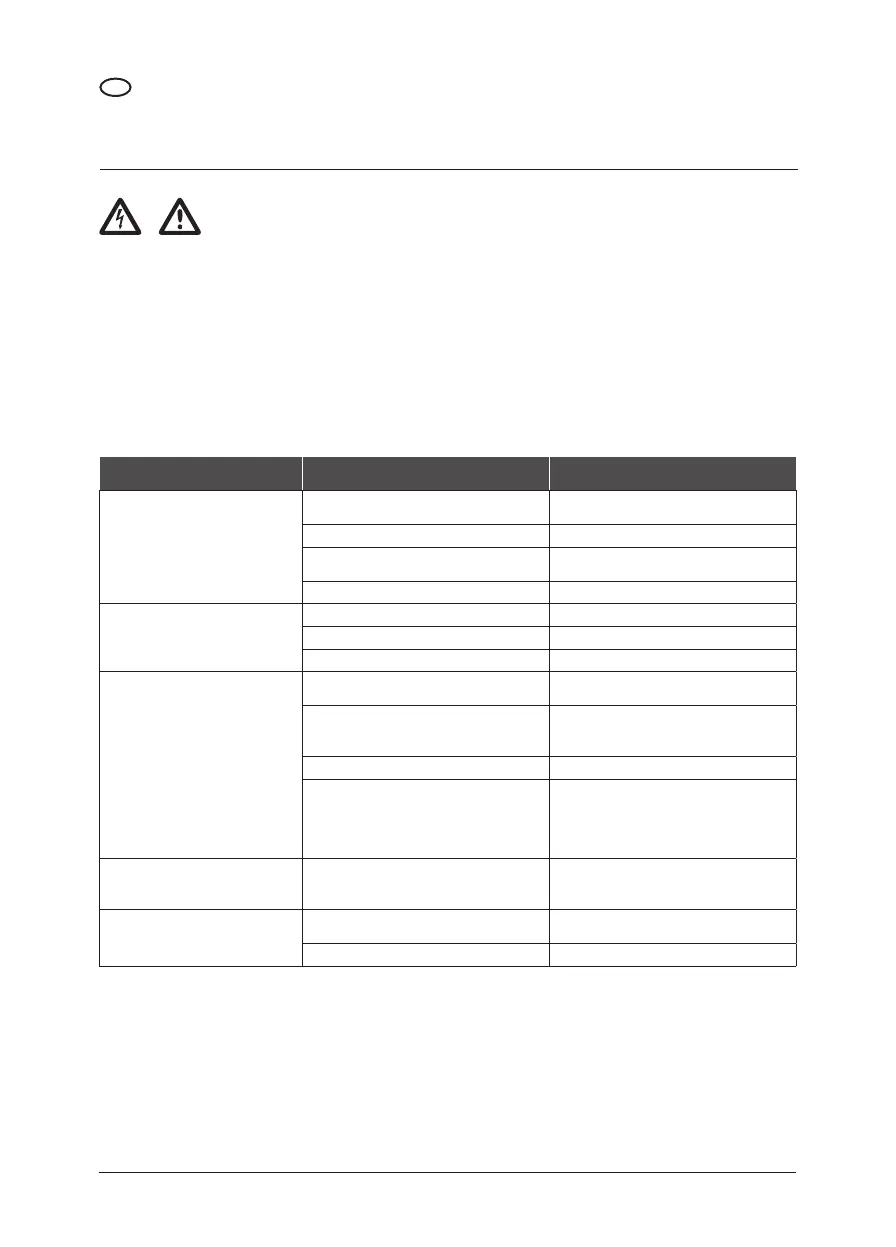

PROBLEM POSSIBLE CAUSE REMEDY

THE PUMP IS NOT RUNNING

1) No water. Red LED light on (FAILURE)*. Identify the cause, and then restart by

pressing the RESTART button.

2) Pump stalled. Identify the cause and unblock the pump.

3) No current. Check that power is present and that the plug has been inserted

properly. The Green LED light (power On) is off*.

4) FLUSSCONTROLL* is faulty. Contact the Customer Assistance Service.

THE PUMP DOES NOT STOP

1) Reset button blocked. Inspect the pump and clean it if necessary.

2) The pump sucks air. See point 4.

3) FLUSSCONTROLL* faulty. Contact the Customer Assistance Service.

THE ELECTROPUMP DOES NOT PUMP WATER,

THE MOTOR DOES NOT RUN

1) No power. Check that power is present and that the plug has been inserted

properly. The Green LED light (power On) is off*.

2) Motor protection tripped. Identify the cause, and then restart by pressing the RESTART* button.

Wait until the system has cooled down if the thermoregulator has

intervened.

3) Defective condenser. Contact the Customer Assistance Service.

4) Shaft blocked. Identify what caused the block:

a) Make sure that the power supply cable has been unplugged

b) Remove the fan cover

c) Try to unblock the shaft by turning the cooling fan.

Contact customer services if the problem persits

THE MOTOR RUNS BUT THE ELECTROPUMP

DOES NOT PUMP LIQUID

1) The pump is sucking air. Check to ensure that joints are leak proof.

Check that liquid levels have not decreased beneath the foot valve.

Check to ensure that the foot valve is unblocked and leak proof.

THE ELECTROPUMP STOPS AFTER RUNNING FOR

A SHORT PERIOD OF TIME BECAUSE ONE

OF THE THERMAL MOTOR CIRCUIT BREAKER TRIPS

1) The power supply does not comply with

the data on the nameplate.

Check the voltage on the power supply cable leads.

2) A solid object is blocking the impellers. Contact customer services.

MAINTENANCE AND TROUBLESHOOTING

CHAPTER 7

• In ordinary conditions, NOCCHI series

electropumps do not require any

maintenance

• To prevent possible problems, it

is advisable to periodically check

the pressure supplied and current

absorption

• A reduction of the pressure may

indicate that the electropump is worn

• Sand and other corrosive materials

present in the delivery fluid cause

a rapid wear and a reduction of

performance

• In this case, it is advisable to use

a filter

• An increase in current absorption

indicates the presence of abnormal

mechanical friction in the pump and/

or the motor

• If the electropump is not going to be

used for a long period of time (i.e.

one year), it is advisable to empty it

completely (by opening the drain cap,

see Fig. 1 n. 10), rinse it with clean

water and store it in a dry location,

where it can be protected from frost

GB

Make sure the machine is disconnected from electric power supply, before performing maintenance

operation.

DANGER - ELECTRIC SHOCK RISK

Loading...

Loading...