ENGLISH

Polaris

®

Prestige Above Ground Sand Filter

|

Owner’s Manual

Page 8

• CLOSED: Closes all passages through the

Multiport Valve.

• WINTER: This valve position leaves the multiport

valve handle disengaged and all passages through

the valve open for draining. Once the lter is

drained, it is recommended that the valve handle

be kept in the Winter position. See winterization

instructions in section 5.6

• BACKWASH: Water passes through lter sand in

reverse and is sent to the waste port. With pump

running, periodically check water clarity in sight

glass. Once water is visibly clear, the backwash

cycle is complete.

• RINSE: Water passes through lter sand to waste.

Use after backwash cycle to clean debris from the

Multiport Valve. Rinse should run for 1-2 minutes.

5.2 Initial Start up

1. Make sure that all connections are secure and that

any glued piping connections or joints have had

sucient time to cure.

2. Backwash lter sand.

• Set multiport valve to backwash.

3. Turn on lter pump.

• Water will discharge from waste port.

• While pump is running, periodically check the

water clarity through the sight glass or at the

waste port.

• Once water is visibly clear the backwash cycle is

complete.

4. Turn o lter pump.

5. Set valve to rinse.

6. Stand clear of lter and turn on the lter pump.

• Water will discharge from waste port.

7. Allow lter to run for 1-2 minutes.

8. Turn o lter pump.

9. Set multiport valve to lter.

10. Stand clear of lter.

11. Turn on lter pump and allow it to run normally.

• Water will discharge to pool from return port.

• Take the pressure reading from the pressure

gauge while the lter pump is running at its

typical ltration RPM.

• Record the PSI on the pressure gauge, this is

the initial startup pressure and and the lter is

clean. A backwash is required when the pressure

consistently reads 10 PSI greater than the initial

startup pressure.

5.3 Operating Pressure

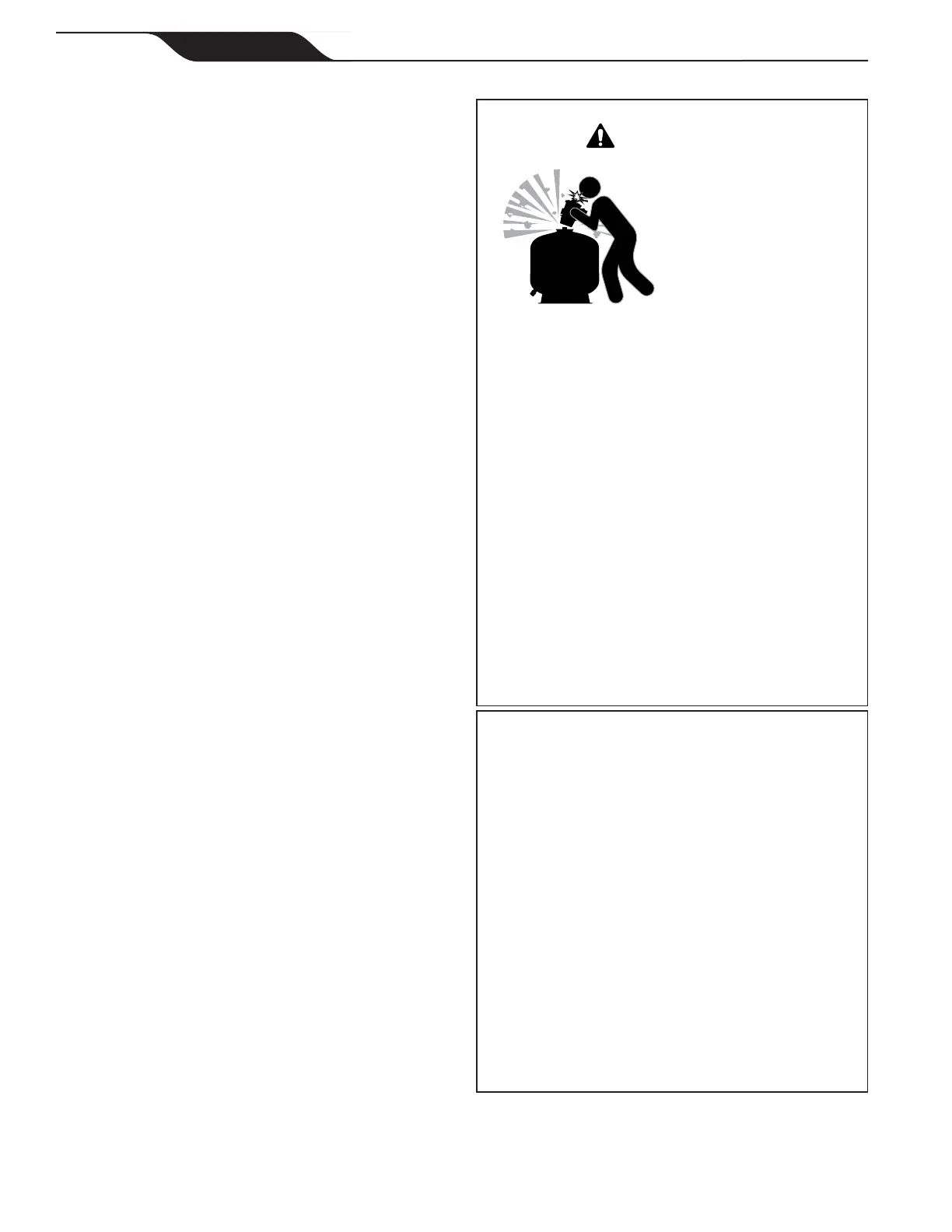

WARNING

X

MAXIMUM OPERATING

PRESSURE OF THE

FILTER IS 35 PSI.

NEVER SUBJECT THE

FILTER TO ANY OPER-

ATING PRESSURE

EXCEEDING 35 PSI

• Do not connect the system to an unregulated

city water system or other external source of

pressurized water producing pressures greater

than 35 PSI.

• This lter operates under high pressure. When

any part of the circulating system, i.e., lter,

pump, valve(s), etc. is serviced, air can enter

the system and become pressurized when the

system is restarted.

• Pressurized air in a system can cause product

failure or also cause the dial valve to be blown

o which can result in death, serious personal

injury or property damage.

• To minimize risk of severe injury or death, the

lter and/or pump should not be subjected to

the piping pressurization test. Local codes may

require the pool piping system to be subjected

to a pressure test. These requirements are

generally not intended to apply to the pool

equipment such as lters or pumps. Polaris pool

equipment is pressure tested at the factory.

If however, this WARNING cannot be followed and

pressure testing of the piping system must include

the lter and/or pump BE SURE TO COMPLY

WITH THE FOLLOWING SAFETY INSTRUC-

TIONS.

• Check all clamps, bolts, lids, lock rings and

system accessories to ensure they are properly

installed and secured before testing.

• RELEASE ALL AIR in the system before testing.

• Water pressure for test must NOT EXCEED

35 PSI

• Water temperature for test must NOT EXCEED

100°F (38°C).

• Limit test to 24 hours. After test, visually check

system to be sure it is ready for operation.

NOTE: These parameters apply only to Polaris

equipment. For non-Polaris equipment, consult the

equipment manufacturer.

The lter is designed to operate eectively based on the

performance curve listed below. At no time is the lter to

be subjected to internal pressures greater than 35 psi.