16

PM 25MV v9 2021-12 Copyright © 2021 Quality Machine Tools, LLC

Section 4 MAINTENANCE

Unplug the 120V power cord before

any maintenance operation!

RECOMMENDED LUBRICANTS

Ball oilers (X and Y leadscrews): Way Oil, such as

Precision Matthews Premium Way Oil

X, Y and Z axis ways: Way Oil, such as Precision Mat-

thews Premium Way Oil

Visible gears such as quill rack and pinion, Z-axis

bevel gears: light general purpose grease, NLGI No. 2,

or equivalent

X Y, and Z leadscrews: Way Oil, such as Precision

Matthews Premium Way Oil

Quill Outer Sliding Surface: Way Oil, such as Preci-

sion Matthews Premium Way Oil

Spindle Bearings: High Speed Spindle Bearing

Grease, such as Kluber Isoex NBU 15

GENERAL OILING

Assuming a clean environment – no abrasive particles

or machining debris – lack of proper lubrication is the

main cause of premature wear. Rotating parts are easy

to lubricate, sliding parts are not. Gibs are tightened for

Remove all machining debris and foreign

objects before lubricating ANYTHING! If need

be, any oil is better than no oil – but use the

recommended lubricants when you can.

Ball oilers

Use a pump-type oil can with tip large enough to more

than span the oiler’s spring-loaded steel ball. Oil pres-

sure will displace the ball, allowing oil to ow, provided

the oil can tip is rmly pressed onto the brass seating.

Before oiling check that the ball is not stuck – press it

lightly with a probe.

the best compromise between rigidity and slideability,

which means practically zero gap between the ways.

Take time to understand exactly which are the bearing

surfaces on the various dovetail surfaces; this is not ob-

vious – some of the interfaces look like bearing surfac-

es, but are simply narrow gaps.

Every few hours of operation: 1. Apply the recommend-

ed way-oil with a dedicated short-bristle brush such as

the type used for applying ux; 2. Use a similar brush to

apply oil or grease to the leadscrews; 3. Apply oil to the

ball oilers, see below.

Quill rack and pinion

Lower and lock the quill. Using a sti ux brush, clean

the visible portions of the rack and pinion. Raise and

lower the quill to expose the remainder of the working

surfaces, locking and cleaning at each setting.

Sindle bearings

See Servicing Quill and Spindle, two pages on.

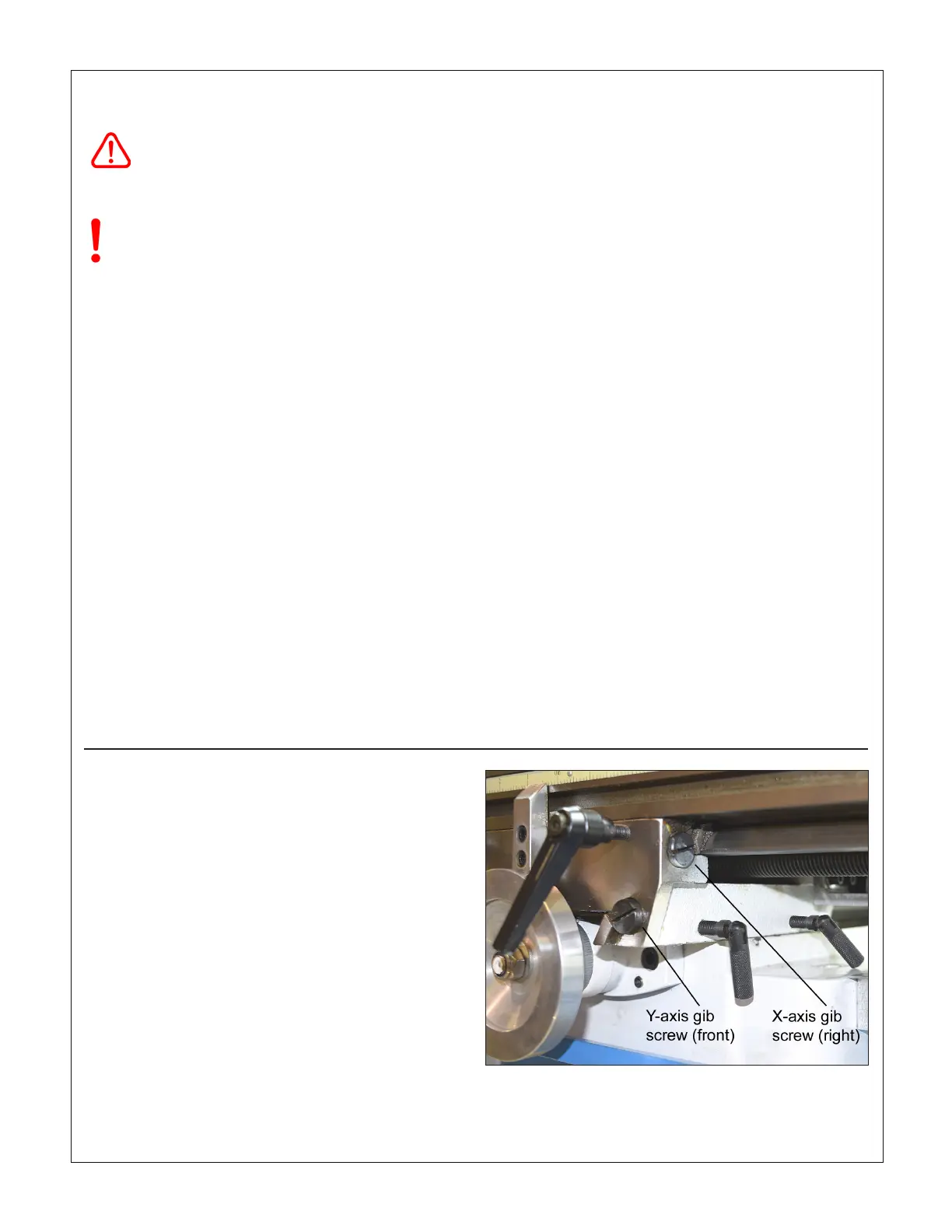

GIB ADJUSTMENT

Gibs on the X, Y and Z axes control the t of the mating

dovetailed surfaces. They are gently-tapered lengths of

ground cast iron located by opposing screws at each

end. Adjusting them is a trial and error process that

takes time and patience. Aim for the best compromise

of rigidity and reasonably free table movement. Too tight

means accelerated wear on the ways and leadscrews.

Too free means workpiece instability, inaccuracies and

chatter.

Both screw heads must be tight against the gib ends.

If you loosen one, tighten the other. Remove the way

covers for access to the back of the Y gib and bottom of

the Z gib.

Figure 4-1 Gib adjustment, X and Y axes

The back adjustment screw for the Y axis gib is under the solid rubber

way cover behind the table. The left adjustment screw for the X axis is

in a similar location on the left side of the saddle casting.

Loading...

Loading...