To de-energize the solenoid and to restore the nonconducting condition, the supply

voltage has to be interrupted.

B. Mechanical end-of-tape switch.

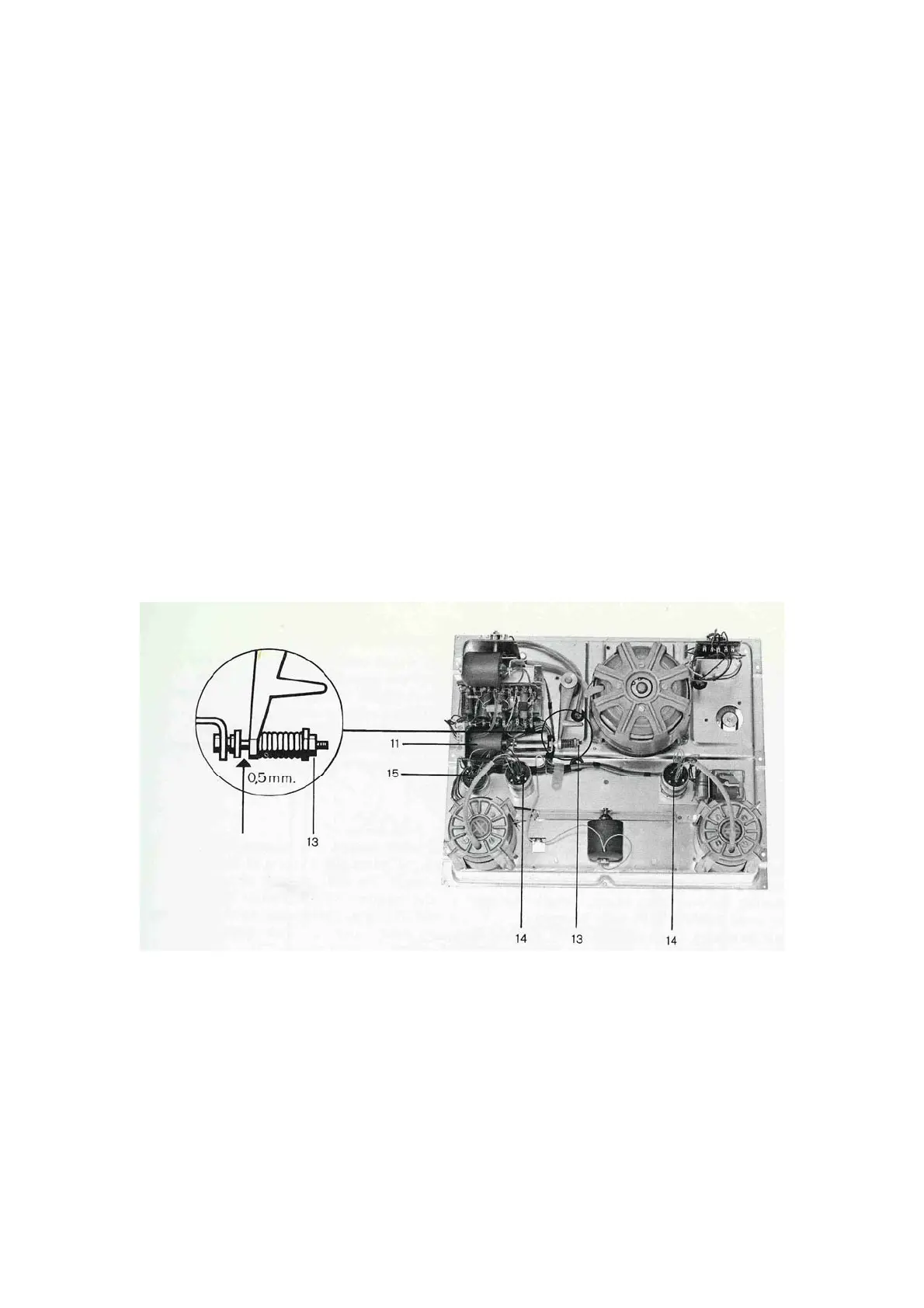

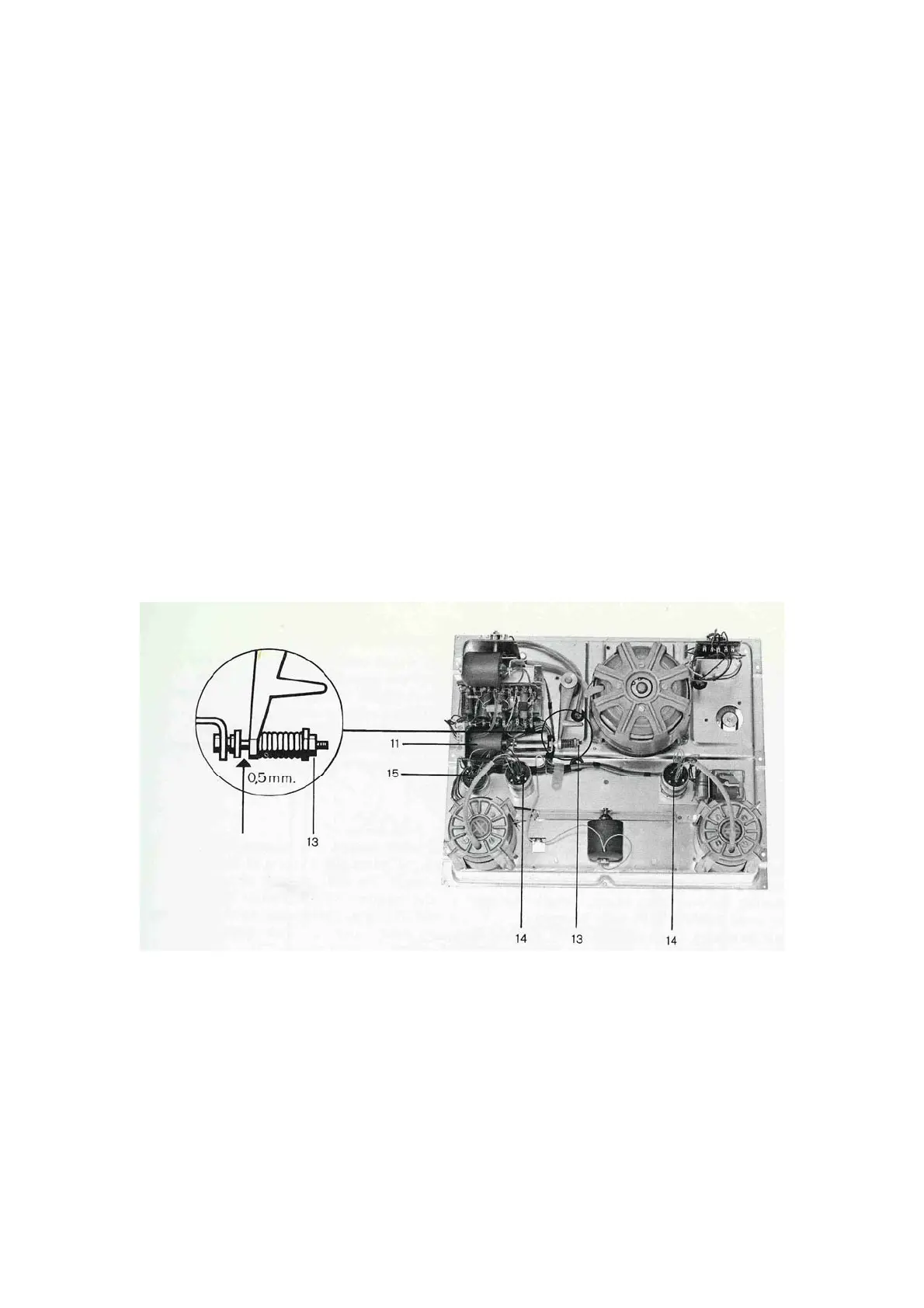

This switch and its associate operating levers must be thoroughly clean to function

correctly. On G-36 recorders up to serial number 36 500, the tape sensing lever

operates a snap-action switch (SE schematic A) which is closed with tape tension

applied. The right position of the switch assembly is essential for correct operation to

be obtained. This adjustment is carried out by slackening the fixing screws and

moving the switch bodily until the snap-action switch closes when the sensing lever

still protrudes by 0.5 to 1 mm from the outer diameter of the tape guide.

On recorders with serial number 36 500 and up, the sensing lever operates a gold-

plated wire contact. This switch opens when tape tension is applied (see BE in

schematic Band 7.736.001-002). Adjustment should be carried out analogue to the

above specifications for the snap-action switch by bending the long wire loop. In the

resting position sufficient contact pressure should be available to make the short wire

loop move beyond the point of contact by approx. 0.5 mm. This is achieved by

bending the contact wires while operating the tape sensing lever by hand.

The end-of-tape switch and its operating lever are then properly adjusted when the

switch remains open (or closed on older models) for any movement of the sensing

lever inside the tape-guide post. Accidental tripping due to sticky splices etc. will

thus be avoided.

2.1.6 Wow and flutter

Loading...

Loading...