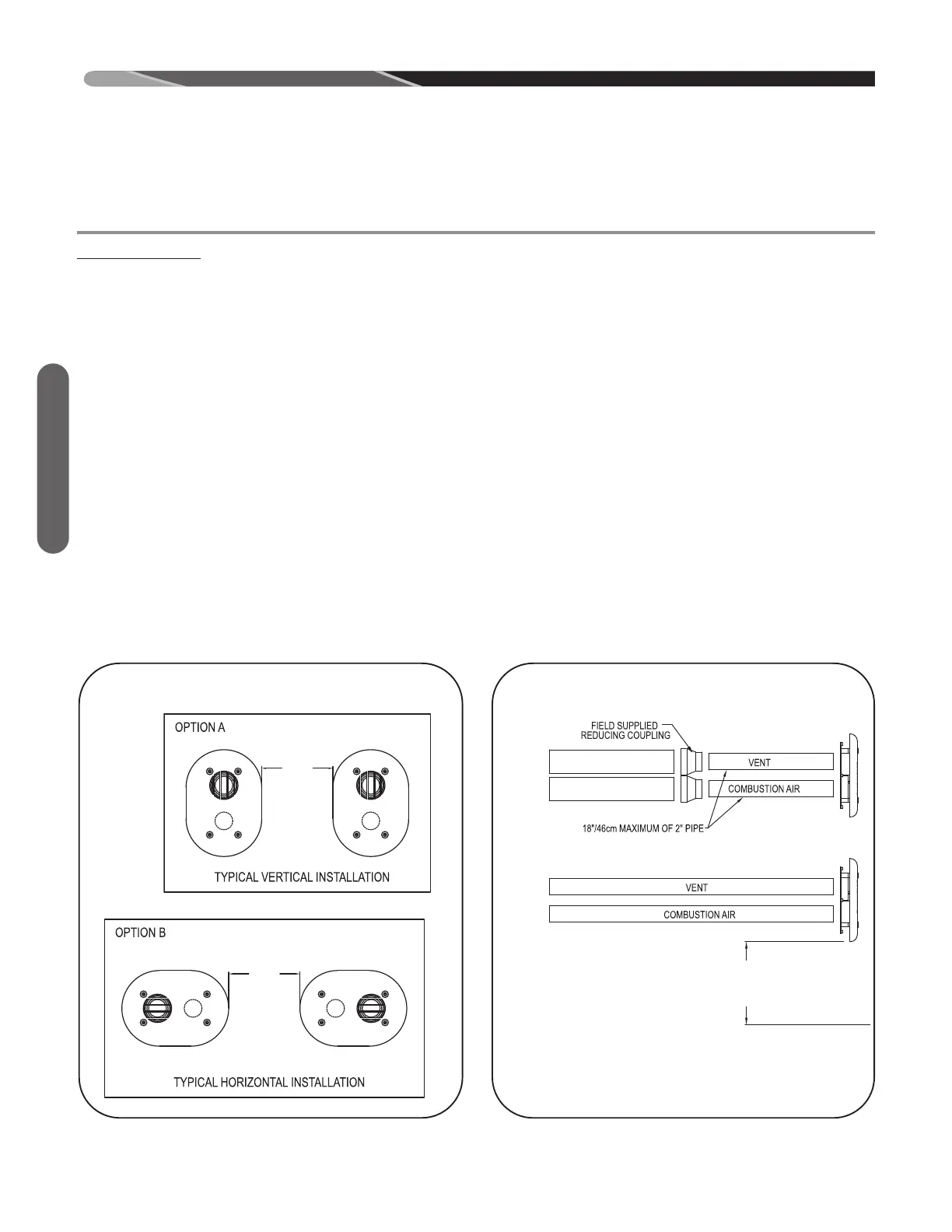

This termination is for horizontal venting only. This termi-

nation may be installed with either a non-direct-vent or a

direct-vent system. When installed as non-direct vent, only

one wall penetration is necessary for the exhaust vent.

IMPORTANT: Do not install on the prevailing winter wind

side of the structure.

IMPORTANT: Maintain a minimum of 12 inches (U.S.)

above grade or the highest anticipated average snow level

(whichever is greater) to the bottom of the vent cover or, in

Canada, terminations must conform with CSA B149.1-10,

Sect. 8.14, Canadian Natural Gas and Propane Installation

Code.

NOTE: Dimensions between the inlet and outlet pipes (di-

rect-vent only) are fixed by the sidewall termination. Other

drawings in this manual which specify minimum and/or

maximum distances (vertical and horizontal) between

pipes do not apply to the sidewall termination kit.

NOTE: Multiventing – NO COMMON VENTING IS PER-

MITTED WITH THIS KIT.

NOTE: With this option a trap on the inlet combustion

air pipe is NOT required.

NOTE: Install the vent and air intake piping into the vent

plate openings. Seal all gaps between the pipes and wall.

BE SURE TO USE SILICONE SEALANT to seal the vent

pipe to the vent cap to permit field disassembly for annual

inspection and cleaning. Also seal all pipe penetrations in

the wall. DO NOT INSTALL VENT KITS ONE ABOVE

THE OTHER to prevent the possibility of condensate

freeze-up or recirculation.

NOTE: Vent should protrude a maximum of 2-1/4 inches

beyond the vent plate. Air intake should protrude a maxi-

mum of 1 inch beyond the vent plate.

NOTE: The RXGY-G02 termination can be used with 3”

vent pipe. A maximum of 18” of 2” pipe can be used be-

fore penetrating the wall.

Complete installation instructions are included with these

kits.

ST-A1194-46

ST-A1194-46

Loading...

Loading...