IMPORTANT: Do not run a flexible gas connector inside the

furnace. The gas pipe gasket in the cabinet does not seal

around a flexible gas line.

If local codes allow the use of a flexible gas appliance con-

nector, always use a new listed connector. Do not use a con-

nector which has previously serviced another gas appliance.

Massachusetts law requires that all flexible connectors be

less than 36”.

It is important to have all openings in the cabinet burner

compartment sealed for proper furnace operation.

IMPORTANT: ENSURE that the furnace gas valve is not to

be subjected to high gas line supply pressures.

DISCONNECT the furnace and its individual manual gas

stop from the gas supply piping during any pressure test-

ing that exceeds 1/2 PSIG. (3.48 kPa).

Natural gas supply pressure must be 5" to 10.5" w.c.

LP gas supply pressure must be 11" to 13" w.c.

This

pressure must be maintained with all other gas-fired

appliances in operation.

The minimum gas supply pressure to the gas valve for

proper furnace input adjustments is 5" w.c. for natural gas,

however 6" to 7" is recommended. The minimum gas sup-

ply pressure is 11" w.c. for LP gas.

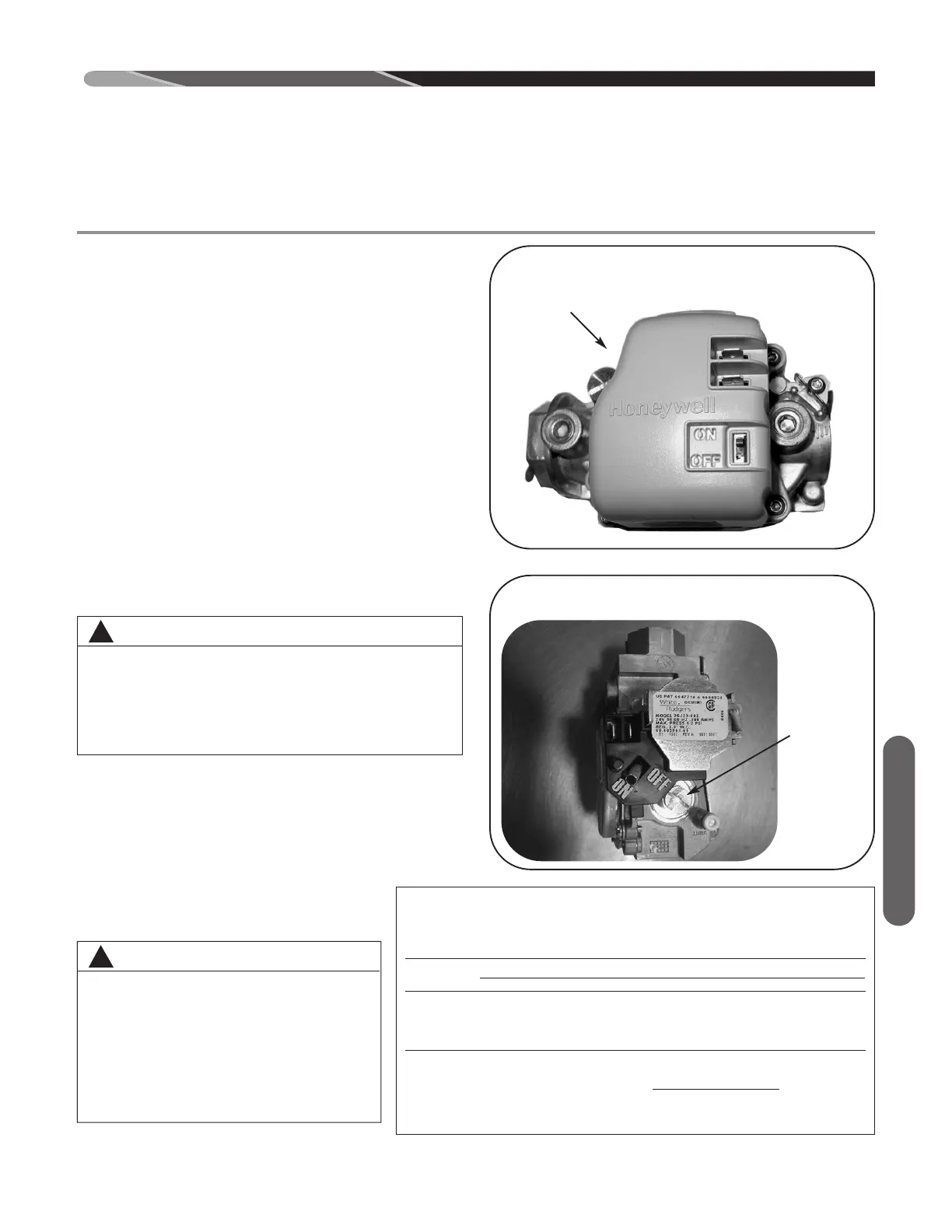

GAS VALVE

This furnace has a 24-volt gas valve. It has ports for measur-

ing supply and manifold gas pressure. The valve body con-

tains a pressure regulator to maintain proper manifold gas

pressure.

A control switch is on the valve body. It can be set to only the

“ON” or “OFF” positions. The gas valve is a

slow-opening valve. See Figures 37A and 37B.

When energized, it takes 2 to 3 seconds to fully

open.

GAS SUPPLY

GAS PRESSURE

FIGURE 37A

HONEYWELL GAS VALVE

TABLE 12

NATURAL GAS PIPE CAPACITY TABLE (CU. FT./HR.)

Capacity of gas pipe of different diameters and lengths in cu. ft. per hr. with pressure drop of 0.3 in. and specific

gravity of 0.60 (natural gas).

Nominal Length of Pipe, Feet

Iron Pipe

Size, Inches 10 20 30 40 50 60 70 80

1/2 132 92 73 63 56 50 46 43

3/4 278 190 152 130 115 105 96 90

1 520 350 285 245 215 195 180 170

1-1/4 1,050 730 590 500 440 400 370 350

1-1/2 1,600 1,100 890 760 670 610 560 530

After the length of pipe has been determined, select the pipe size which will provide the minimum cubic feet per hour

required for the gas input rating of the furnace. By formula:

Gas Input of Furnace (BTU/HR)

Cu. Ft. Per Hr. Required =

Heating Value of Gas (BTU/FT

3

)

The gas input of the furnace is marked on the furnace rating plate. The heating value of the gas (BTU/FT

3

) may be de-

termined by consulting the local natural gas utility or the LP gas supplier.

!

CAUTION

ELEVATIONS ABOVE 2000 FT. REQUIRE THAT THE FUR-

NACE INPUT RATING BE ADJUSTED AND THAT THE SIZE

OF THE BURNER ORIFICES BE RECALCULATED BASED

ON ELEVATION AND GAS HEATING VALUE. THE BURNER

ORIFICES MAY (OR MAY NOT) NEED TO BE CHANGED.

SEE THE SECTION TITLED “HIGH ALTITUDE INSTALLA-

TIONS” OF THIS BOOK FOR INSTRUCTIONS.

!

WARNING

NEVER PURGE A GAS LINE INTO THE COM-

BUSTION CHAMBER. NEVER USE MATCHES,

FLAME OR ANY IGNITION SOURCE FOR

CHECKING LEAKAGE. FAILURE TO ADHERE

TO THIS WARNING CAN CAUSE A FIRE OR

EXPLOSION RESULTING IN PROPERTY DAM-

AGE, PERSONAL INJURY OR DEATH.

TO CHECK FOR GAS LEAKAGE, USE AN AP-

PROVED CHLORIDE-FREE SOAP AND WATER

SOLUTION, OR OTHER APPROVED METHOD.

Gas Supply

REGULATOR CAP

73

FIGURE 37B

WHITE RODGERS GAS VALVE

REGULATOR

CAP