23

MOST COMMON ADVANTAGEPLUS INSTALLATION CONCERNS

VENTING:

VENT LENGTH TOO LONG - OVER 85' (26 m)

VENTING NOT PITCHED PROPERLY - CONDENSATE BUILD UP IN VENT

EXHAUST GAS RE-CIRCULATION - VENT TERMINALS NOT USED, WRONG FITTINGS USED, SIGHT PROBLEMS

BUSH IN FRONT OF VENT TERMINAL

INSIDE CORNER OF BUILDING FOR VENT LOCATION

OVERHANG WITH VENT UNDERNEATH

COMPOUND ROOF PITCH, OR ABOVE ROOF FIRE WALL

ADDITIONAL FITTINGS INSTALLED INTO TERMINALS

VENT SIZED FROM 3" TO 4" BY USING BUSHINGS - INSTEAD OF REDUCING COUPLING OR REDUCING ELBOW

VENT CHANGED FROM 3" TO 4" - WITHOUT GOING REQUIRED 15' (4.6 m) ON BOTH INTAKE AND EXHAUST

VENTING NOT CLEANED AND GLUED TOGETHER FOR PRESSURE TIGHT JOINTS

INTAKE AIR CONTAINING EXHAUST FROM ANOTHER VENT OR APPLIANCE

GAS SUPPLY:

GAS PRESSURE TOO LOW - NEED 3.5" WC (0.87 kPa) GAS PRESSURE UP TO 14" WC (3.5 kPa) GAS PRESSURE

GAS METER TOO LOW IN CAPACITY

GAS REGULATOR NOT SIZED PROPERLY - TOO LOW IN CAPACITY

GAS PIPE TOO SMALL - 3/4" MINIMUM GAS SUPPLY SIZE

GAS REGULATOR TOO CLOSE TO APPLIANCE - NEED 10' OF PIPE FOR EVERY 200,000 BTU’S PER HOUR

GAS REGULATOR WITH LONG VENT OR BLEED VENT ORIFICE - REGULATOR SLOW TO RESPOND

GAS METER RESTRICTION, OR IN NEED OF REPAIR/REPLACEMENT

GAS SUPPLY PRESSURE DROPS BELOW 3.5" WC (0.87 kPa) WHEN APPLIANCE FIRES

ELECTRICAL:

APPLIANCE NOT GROUNDED

ELECTRICAL POLARITY REVERSED - FLAME WILL LIGHT BUT GO BACK OUT IN 4-6 SECONDS VOLTAGE TOO LOW OR TOO HIGH

APPLIANCE CYCLES, BUT NO IGNITION - REMOVE ANY CORROSION FROM SPARK ELECTRODE AND RECTIFIER. CHECK GAP

SPACING ON SPARK ELECTRODE. SHOULD BE 1/4" SPACING.

PLUMBING: DIELECTRIC UNIONS INSTALLED - RUSTY WATER

CONDENSA

TE:

CONDENSATE LINE NOT

PITCHED

T

O DRAIN

CONDENSA

TE LINE NOT

DRAINING DUE

T

O LONG RUN WITHOUT

VENT

CONDENSA

TE PUMP

NOT

WORKING

CONDENSATE TRAP PLUGGED

BURNER:

EXTREMEL

Y LOUD BANG ON IGNITION - BURNER FAILED OR END CAP OFF

RED BURNER DECK AS SEEN THROUGH VIEW PORT - GAS VALVE NEEDS ADJUSTMENT

GAS VALVE:

PUFFING ON IGNITION -

ADJUST

GAS V

AL

VE

LOUD POP

ON IGNITION,

THEN RUNNING SMOOTH -

ADJUST

GAS V

AL

VE

HUFF

AND PUFF DURING OPERA

TION - ADJUST GAS VALVE

RUNNING GREAT BUT INTERMITTENTLY HUFFING OR POPPING - CHECK FOR RE-CIRCULATION UNDER VENTING

IT IS IMPORTANT TO NOTE FOR MAINTENANCE PURPOSES: THE THREAD ON THE END OF THIS GAS VALVE AND NIPPLE IS A

LEFT HAND THREAD.

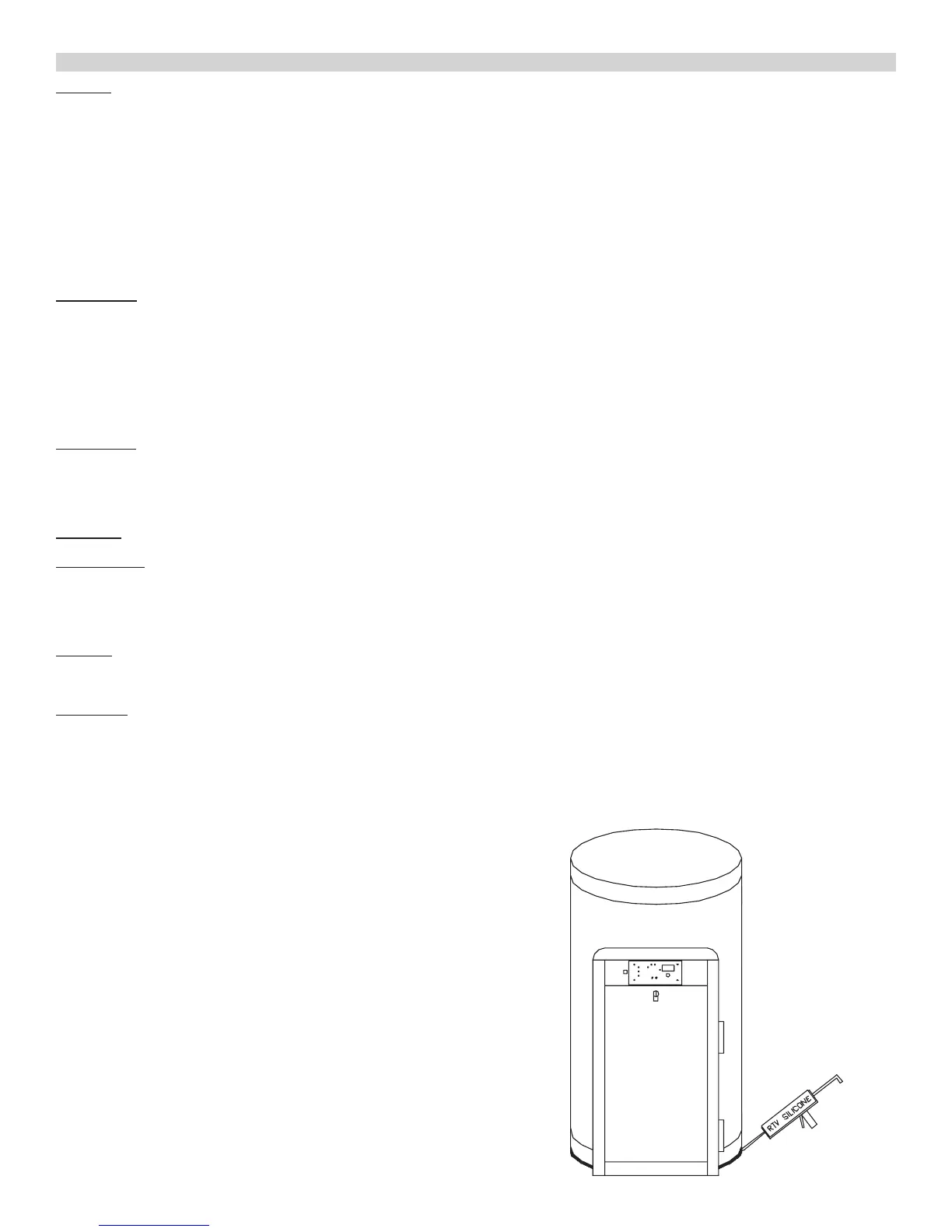

SEALING ADVANTAGEPLUS AS PER N.S.F. STANDARD

NUMBER 5

TO SEAL THE BASE OF BOOSTER TO THE FLOOR TO

PREVENT SEE PAGE UNDERNEATH, PER N.S.F.

STANDARD #5 - APPLY A 3/8" BEAD OF RTV SILICONE

(AS SHOWN HERE), COMPLETELY AROUND TANK.

Loading...

Loading...