Loading...

Loading...

Do you have a question about the Rheem GHE100-160 and is the answer not in the manual?

| Brand | Rheem |

|---|---|

| Model | GHE100-160 |

| Category | Water Heater |

| Language | English |

Covers electrical shock, flammable liquids, and vapor risks.

Discusses safe water temperature settings to prevent scalding.

Presents a block diagram illustrating electrical connections.

Illustrates wiring connections between components.

Shows top view with labeled components.

Describes blower, gas valve, temperature sensors, and anode controller.

Explains condensate trap, igniter, flame probe, main controller, and LCD display.

Describes pressure switches, temperature probes, leak sensor, and burner.

Guides through initial setup, enabling, and temperature adjustment.

Covers display, network, differential temp, and time/date settings.

Accesses status, service, alarms, health, and Wi-Fi information.

Shows alarms, provides more info, and details system health status.

Lists and explains status messages shown on the control board.

Describes initial power-up and initiating a heat call.

Covers pre-purge, ignition activation, and flame detection.

Details burner operation and the post-purge cycle.

Describes the idle state and how the unit calls for heat.

Explains flame detection and the Energy Cut Off switch.

Explains pressure switches and the vent temperature sensor's roles.

Covers auto-resume after power loss and ignition retry logic.

Describes the condensate removal tube and its maintenance.

Details ignition lockout failures and unstable flame issues.

Addresses intake switch and PoF switch errors.

Covers temperature sensor, flue temp, blower feedback, and RPM mismatch errors.

Troubleshoots anode communication, relay, and controller errors.

Addresses time clock, leak detection, and shut-off valve errors.

Troubleshooting guidance for powered anode controller communication and alerts.

Procedure for checking inlet gas pressure and verifying flow.

Steps for adjusting the gas valve for optimal CO2 levels.

Instructions for replacing ignition board, LCD, blower motor, temp sensor, igniter, flame sensor, switches, and exhaust sensor.

Step-by-step guide for removing and installing the burner assembly.

Introduces BACnet capability, protocol, and accessing configuration settings.

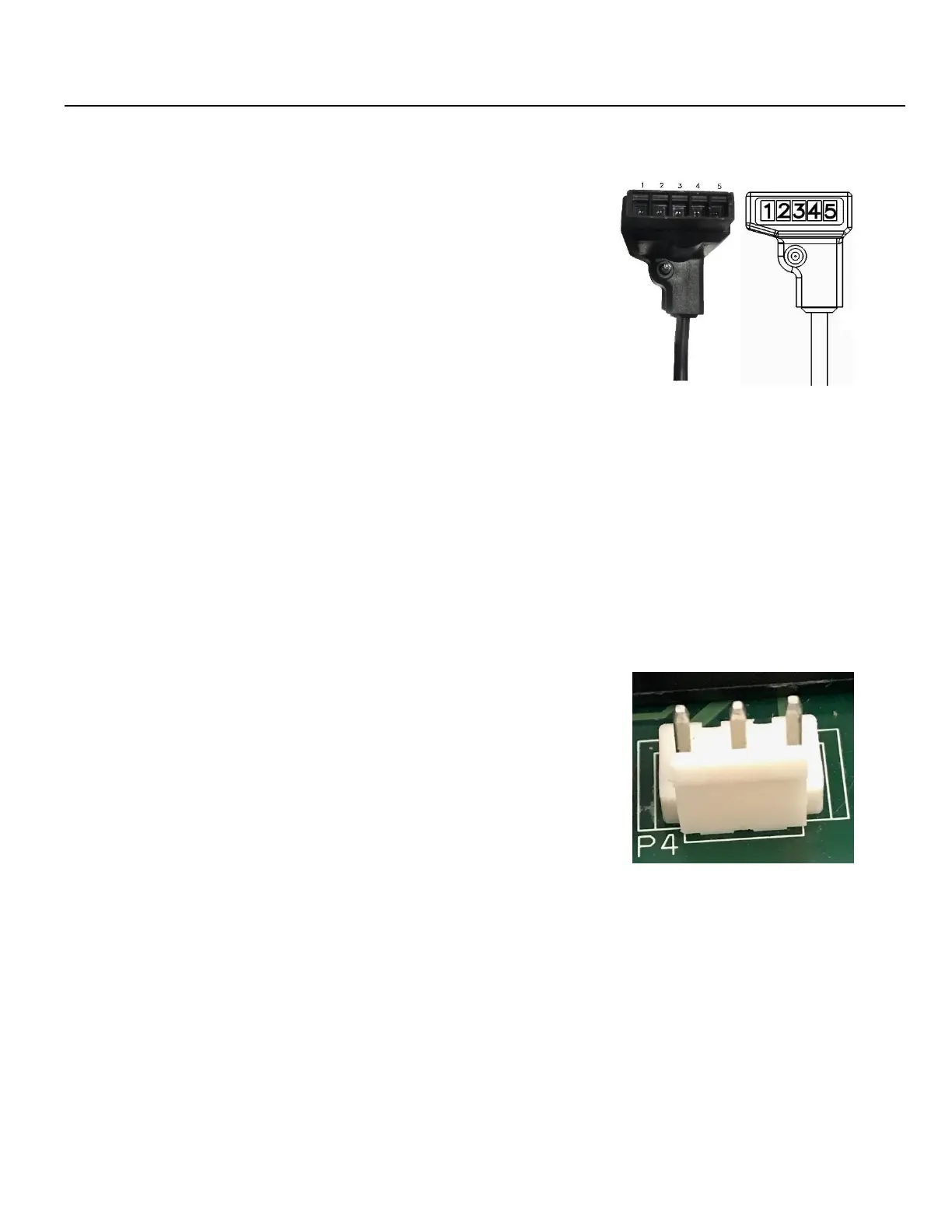

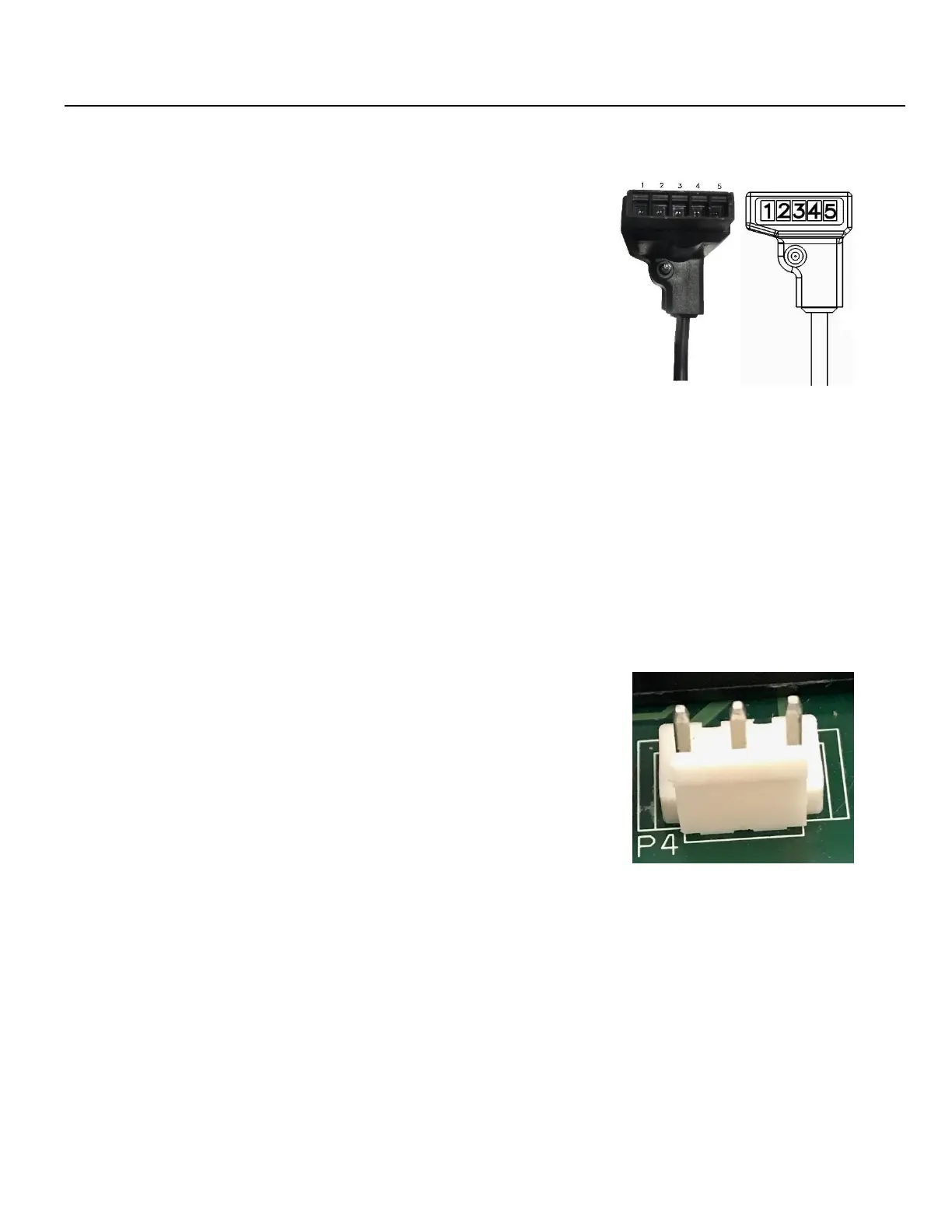

Provides pinout, instructions, and details for BACnet settings.

Explains the proprietary auto shut-off system for leak prevention.