37

GAS SUPPLY AND PIPING

GAS SUPPLY

THIS FURNACE IS EQUIPPED AT

THE FACTORY FOR USE ON

NATURAL GAS ONLY.

CONVERSION TO LP GAS

REQUIRES A SPECIAL KIT IS

AVAILABLE AT THE DISTRIBUTOR.

FAILURE TO USE THE PROPER

CONVERSION KIT CAN CAUSE

F

IRE, CARBON MONOXIDE

POISONING, EXPLOSION,

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH. See the

conversion kit index supplied with the

furnace. This index identifies the

proper LP Gas Conversion Kit

required for each particular furnace.

IMPORTANT: Any additions, changes

or conversions required for the

furnace to satisfactorily meet the

application should be made by a

qualified installer, service agency or

the gas supplier, using factory-

specified or approved parts.

IMPORTANT: Connect this furnace

only to gas supplied by a commercial

utility.

IMPORTANT: U.L. or CSA

recognized fuel gas and CO

detector(s) are recommended in all

applications, and their installation

should be in accordance with the

manufacturer’s recommendations

and/or local laws, rules, regulations or

customs.

GAS PIPING

Install the gas piping according to all

local codes and regulations of the

utility company.

If possible, run a separate gas supply

line directly from the meter to the

furnace. Consult the local gas

company for the location of the

manual main shut-off valve. The gas

line and manual gas stop must be

adequate in size to prevent undue

pressure drop and never smaller than

the pipe size to the gas valve on the

furnace. Refer to Table 6 for the

recommended gas pipe size. See

Figure 35 for typical gas pipe

connections.

Install a ground joint union within 3 ft.

of the cabinet to easily remove the

gas valve assembly. Install a manual

gas stop valve in the gas line outside

the furnace casing. The manual gas

stop should be readily accessible to

turn the gas supply on or off. Install a

drip leg in the gas supply line as close

to the furnace as possible. Always

!

WARNING

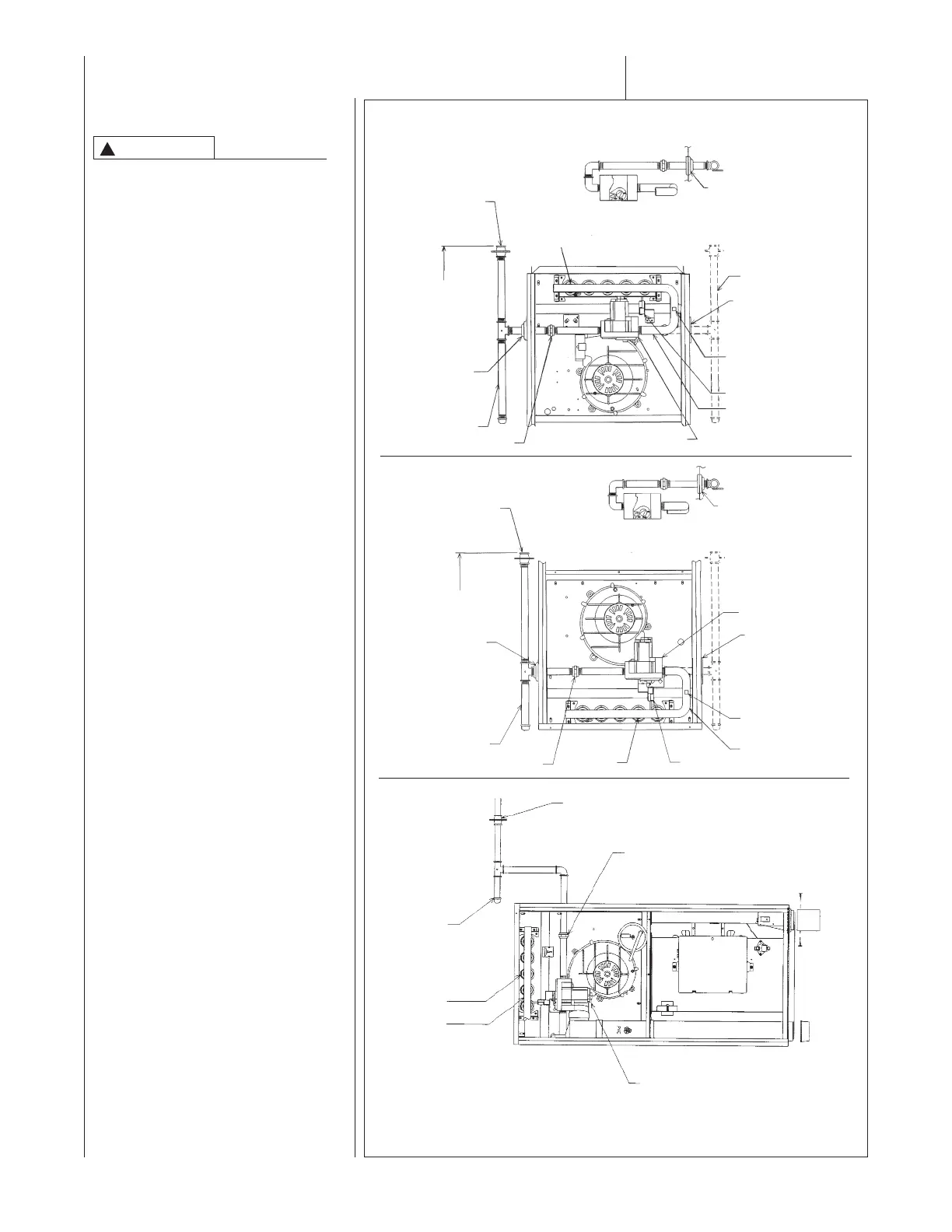

FIGURE 35

G

AS PIPING INSTALLATION

G

ROMMET

TOP VIEW OF GAS LINE AND VALVE

IN OPT. POSITION

N

OTE: WHEN GAS LINE

IS IN OPT. POSITION,

SWAP LOCATION OF

G

ROMMET AND PLUG.

OPT. GAS LINE

P

OSITION

PLUG

(IN NORMAL

P

OSITION)

M

ANIFOLD

PRESSURE

TAP

I

GNITOR

MANIFOLD

G

AS VALVE

U

NION

DRIP LEG

GROMMET

(IN NORMAL

P

OSITION)

4

TO 5 FEET

ABOVE FLOOR

REQ’D BY

S

OME

UTILITIES.

MANUAL

GAS

STOP

B

URNERS

G

ROMMET

TOP VIEW OF GAS LINE AND VALVE

I

N OPT. POSITION

M

ANUAL

G

AS

S

TOP

4

TO 5 FEET ABOVE

FLOOR REQ’D BY

SOME UTILITIES.

GROMMET

(IN NORMAL

POSITION)

DRIP LEG

UNION

G

AS VALVE

BURNERS

MANIFOLD

IGNITOR

MANIFOLD

PRESSURE

TAP

PLUG

(IN NORMAL

POSITION)

N

OTE: WHEN GAS

LINE IS IN OPT.

POSITION, SWAP

L

OCATION OF

GROMMET AND

PLUG.

DOWNFLOW

I328

UPFLOW

MANUAL GAS STOP

UNION

DRIP LEG

BURNERS

MANIFOLD

GAS VALVE

I524

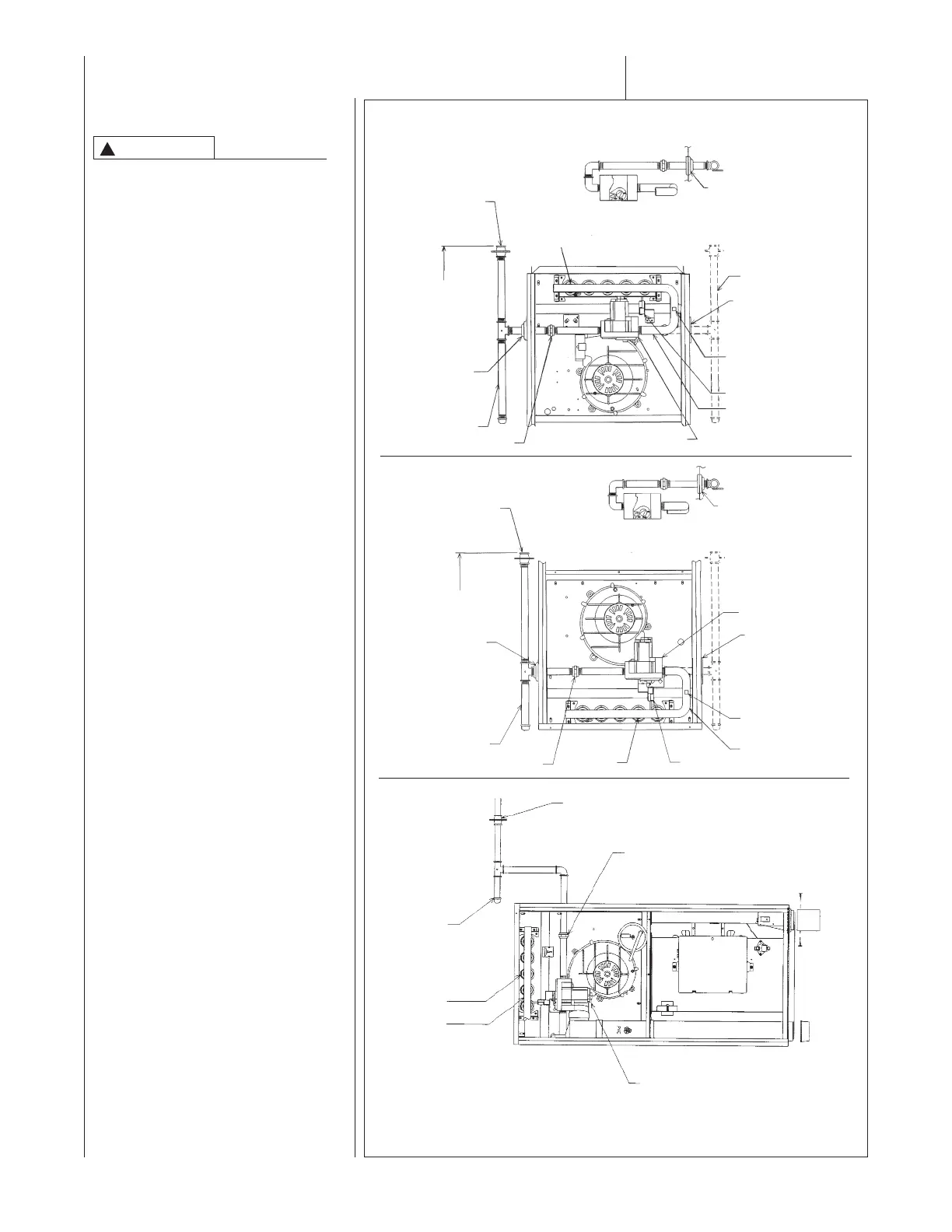

IMPORTANT: DO NOT RUN A FLEXIBLE GAS CONNECTOR INSIDE THE

UNIT. Extend the 1/2" black pipe from the gas valve to the outside of the cabinet.

HORIZONTAL

Loading...

Loading...