• Translucent paper easily absorbs humidity and becomes curled. Remove curl in the translucent

paper before loading.

• Remove copied or printed sheets one by one.

• When loading coated paper:

• To print on coated paper: press the [User Tools] icon ( ), press [Tray Paper Settings], and

then, for each tray's [Paper Type] be sure to specify [Paper Type] to [Coated: Matte], and

[Paper Thickness] to the appropriate paper thickness.

• To print on high-gloss coated paper: press the [User Tools] icon ( ), press [Tray Paper

Settings], and then, for each tray's [Paper Type], be sure to set [Paper Type] to [Coated:

Glossy].

• When loading coated paper or glossy paper, always fan the paper before using it.

• If a paper jam occurs or if the machine makes a strange noise when feeding stacks of coated

paper, feed the coated paper from the bypass tray one sheet at a time.

• After continuous printing of A5 , A6 , envelopes or other smaller custom paper sizes, printing

on different sized paper may require a wait of up to 1 minute for adjustments.

Thick paper

This section gives you various details about and recommendations concerning thick paper.

When loading thick paper of 106–300 g/m

2

(28 lb. Bond–110 lb. Cover), follow the

recommendations below to prevent misfeeds and loss of image quality.

• Store all your paper in the same environment - a room where the temperature is 20–25°C (68–

77°F) and the humidity is 30–65%.

• When loading paper in the paper trays, be sure to load at least 20 sheets. Also, be sure to position

the side fences flush against the paper stack.

• Jams and misfeeds can occur when printing on thick smooth paper. To prevent such problems, be

sure to fan smooth paper thoroughly before loading them. If paper continues to become jammed or

feed in together even after they are fanned, load them one by one from the bypass tray.

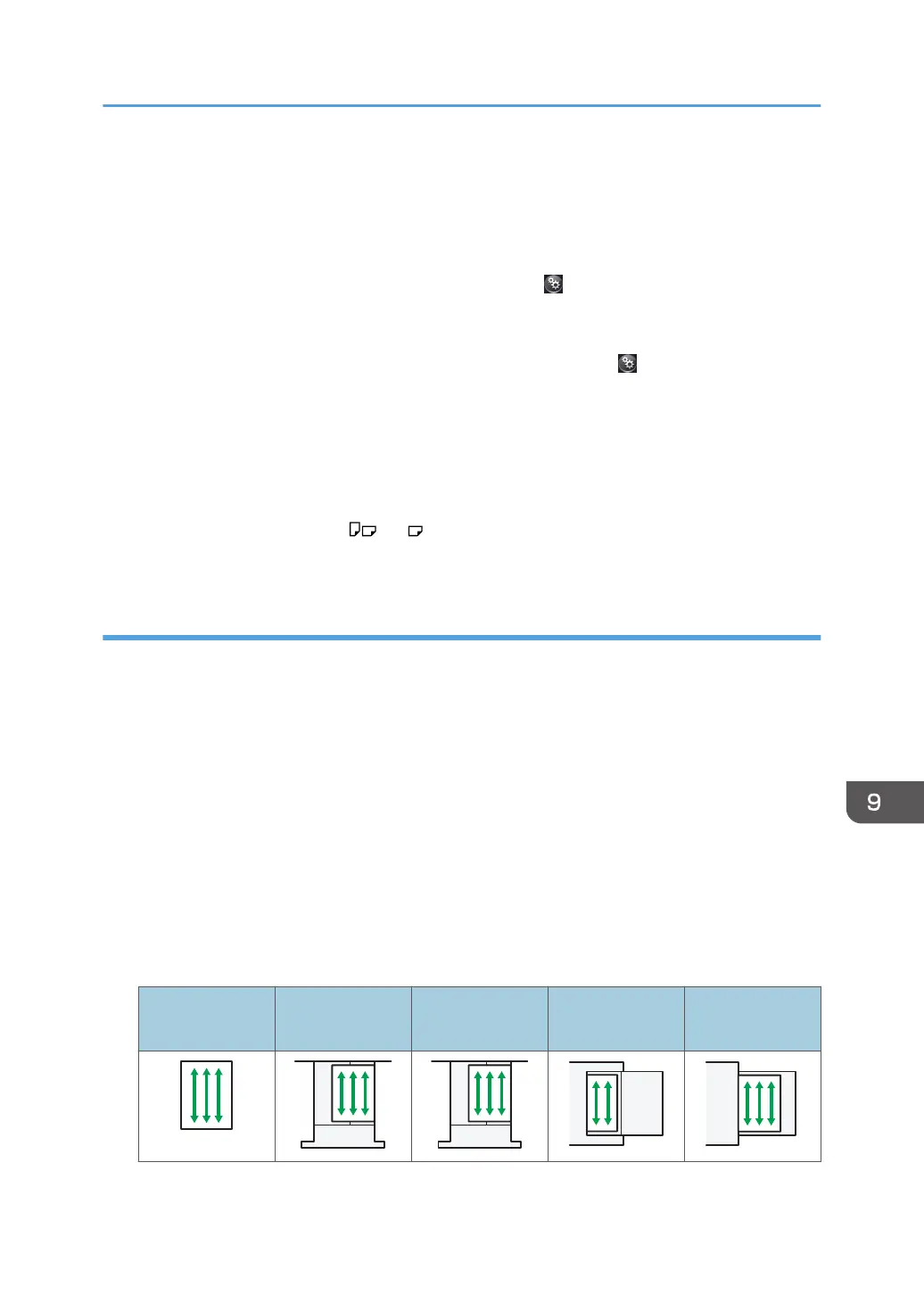

• When loading thick paper, set the paper direction according to its grain, as shown in the following

diagram:

Direction of

paper grain

Tray 1 or Tray 3

(LCT)

Trays 2–4 Large capacity

tray (LCT)

Bypass tray

Recommended Paper

177

Loading...

Loading...