5

placed between the two ring gears. The bevel pinion can then

be engaged with the two ring gears.

10. With shims (121) in place, insert the pinion shaft assembly

into the side of the drive head housing, and bolt in place with

seven cap screws (124), and washers (123).

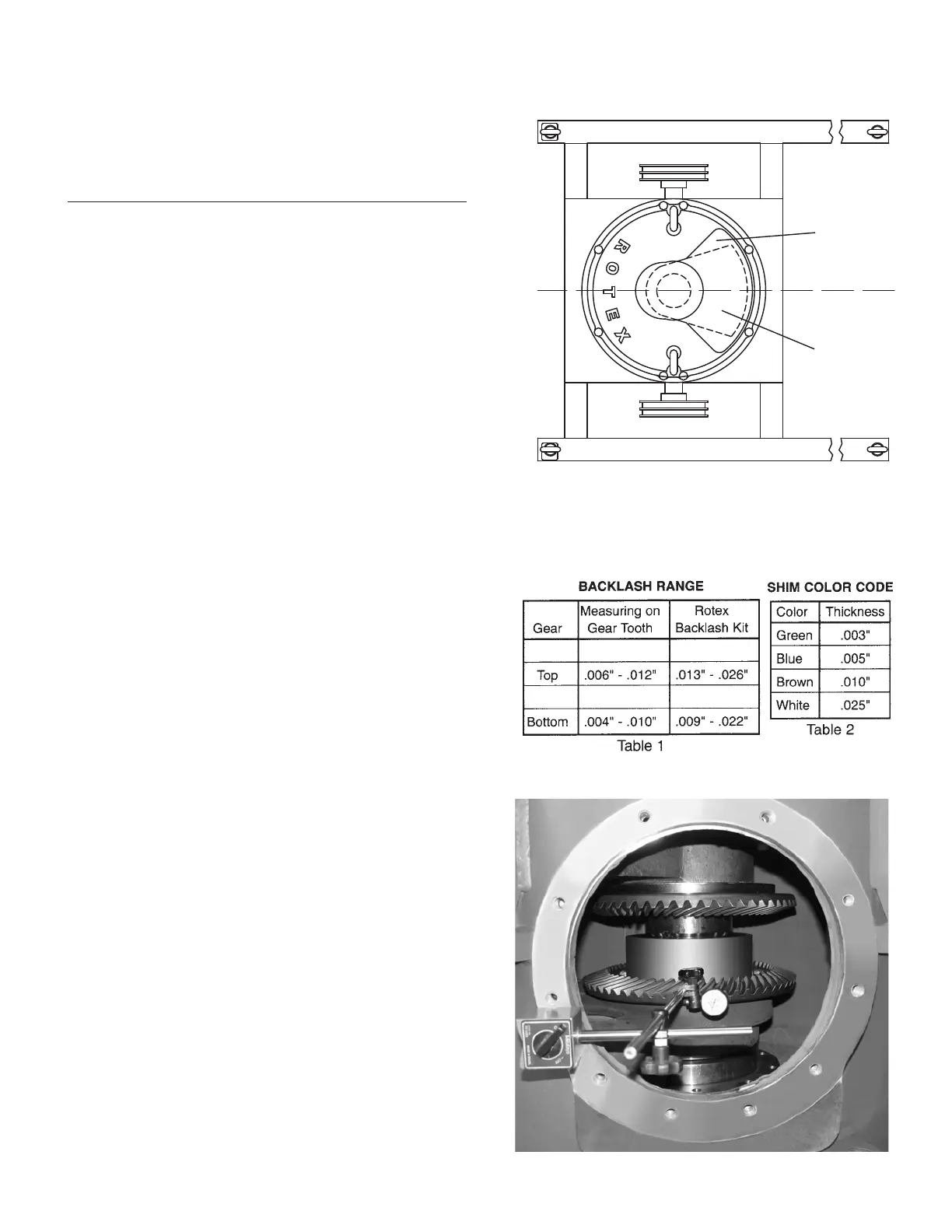

SETTING CLEARANCE BETWEEN

GEARS AND PINION

The backlash between the ring gears and pinion should be set

to the figures in Table 1, depending on the method being used.

The vertical adjustment for gear alignment is accomplished

by means of shims (55) which are placed between the lower

bearing rest casting (60) and the lower bearing support collar

(54).

The horizontal adjustment for backlash between the pinion and

the gears is accomplished by means of shims (121) between the

pinion shaft housing (122) and the drive head housing.

Table 2 shows the color coding for shim thickness.

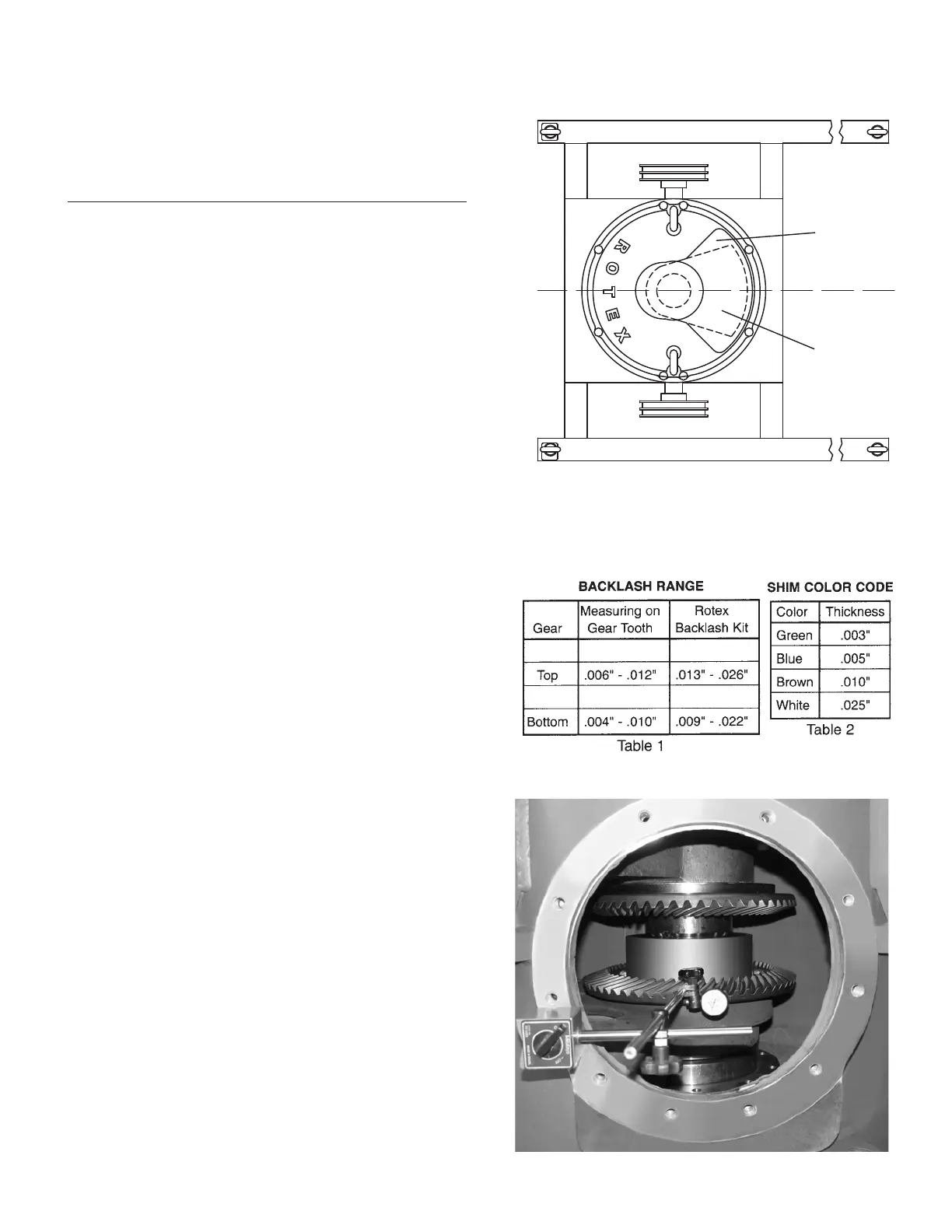

To check the backlash between gears, first lock the pinion shaft

by clamping the shaft to a threaded rod which has been inserted

in one of the tapped holes in the pinion housing. If measuring

directly on the gear teeth, insert a dial indicator into the drive

head housing through the inspection port, so that the indicator

probe is in contact with the face of a tooth on the bottom ring

gear.

If using the ROTEX Backlash Checking Kit, thread the rod into

the tapped hole in the side of the minor weight hub and tighten

slightly. The rod should protrude through the inspection port at

right angles to the machined face of the inspection port. Mount

the magnetic back indicator on the inspection port face with the

indicator probe in contact with the threaded rod (see Figure 3).

NOTE: The threaded rod must not be used to move the weights

while taking backlash readings. Doing so will result in highly

erroneous readings.

Attempt to move the minor balance weight casting and read the

deflection on the dial indicator.

Take a backlash measurement on the upper ring gear by

applying the steps listed above to the major weight (see Figure

2). Move the crankshaft and read the deflection on the dial

indicator.

Once this has been done, rotate both the minor balance casting

and the major balance casting 180 degrees, and then take

another reading.

If the readings on the bottom gear are too high or the top gear

too low, shims must be added under the lower bearing rest to

raise the crankshaft assembly. If the readings on the bottom gear

are too low or the top gear too high, shims must be removed

from under the lower bearing rest. Removal or addition of shims

under the lower bearing rest requires removal of the pinion and

lifting of the crankshaft assembly.

Right or Left Hand Drive - Balance weights must be positioned

one above the other 90° to center line of pinion shaft.

BALANCE WEIGHT POSITIONS FOR

DRIVE HEAD REASSEMBLY

Figure 1

Pinion Shaft

Left-Hand Drive

Pinion Shaft

Front Drive

Pinion Shaft

Rear Drive

Pinion Shaft

Right-Hand Drive

Major Weight

Minor Weight

Machine

Centerline

FIGURE 2

Loading...

Loading...