OPERATION

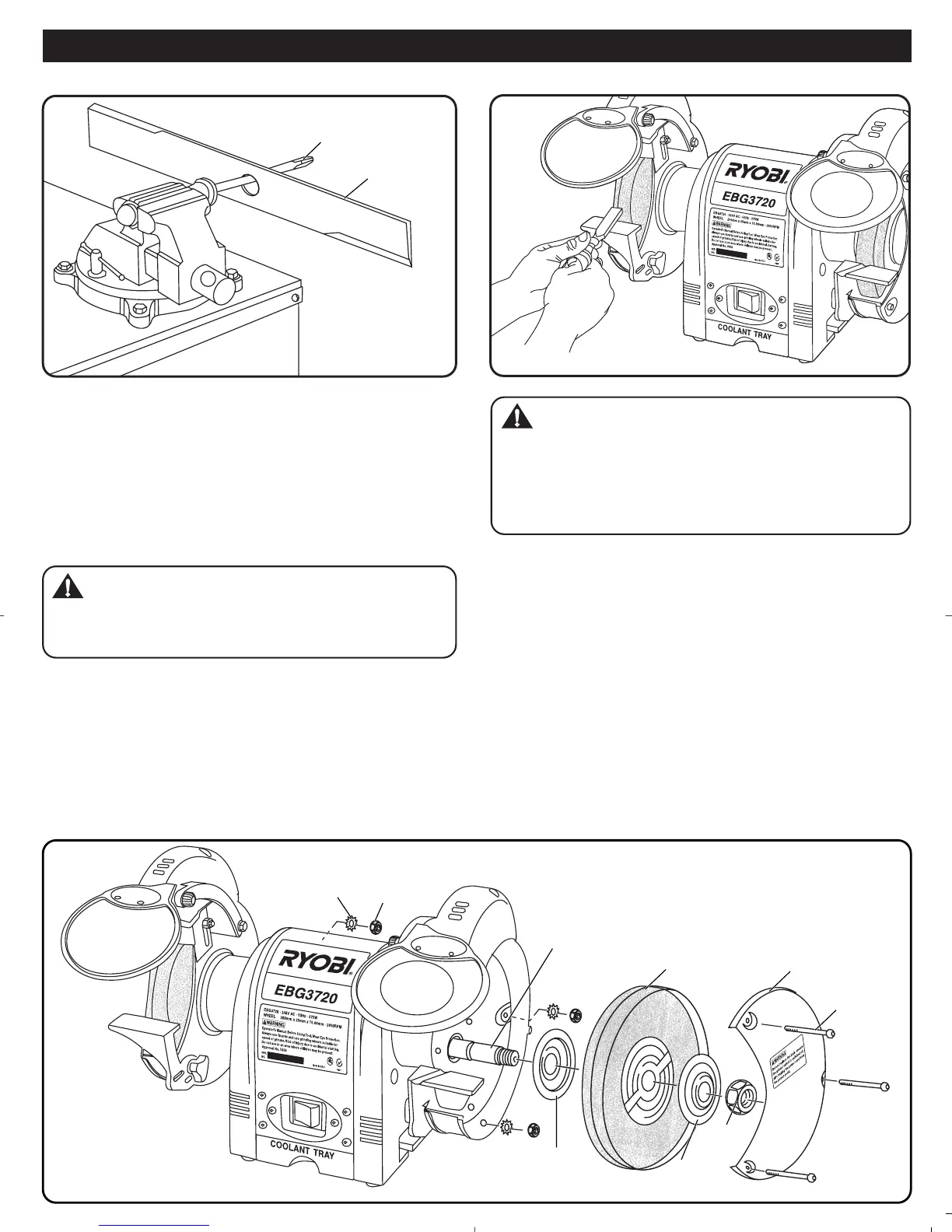

LAWN MOWER BLADES

See Figure 8.

Lawn mower blades are usually sharpened on only one

edge and dressed up slightly on the other. Perform this

sharpening process on both cutting ends of the blade.

After sharpening, be sure to balance the blade by

removing additional material.

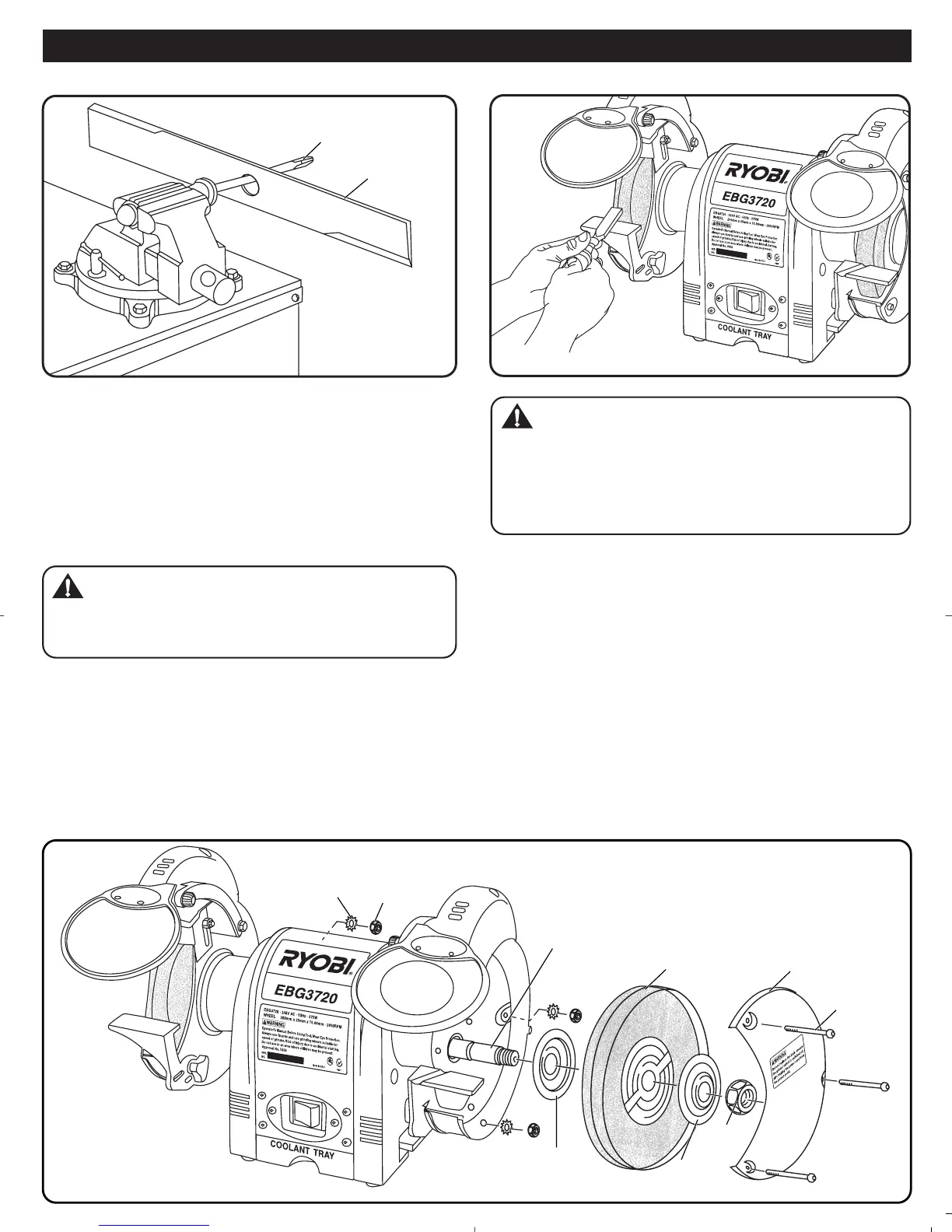

WHEEL REPLACEMENT

See Figure 10.

If you must replace a grinding wheel, be sure to obtain

one with a safe rated speed at least as high as the "no

load speed" RPM marked on the data plate of the grinder

and which is marked to comply with SAA.

To replace the grinding wheel, remove the wheel cover

by loosening the screws, Loosen the wheel nut in a

clockwise direction for the left side and a counterclockwise

direction for the right side. Remove the outer flange and

grinding wheel. To install a new grinding wheel. reverse

the above procedure. Be sure the grinding wheel and outer

flange are properly seated on the spindle shaft.

CHISELS AND SCREWDRIVER BLADES

See Figure 9.

When sharpening chisels and screwdrivers, work rest should

support the chisel at the correct angle against the wheel.

WARNING:

Always disconnect the bench grinder from the power

source before performing any assembly or adjustment.

Failure to do so could result in accidental starting resulting

in possible serious personal injury.

CAUTION

An unbalanced lawn mower blade may cause excessive

vibration which will damage the lawn mower

CHISEL SHARPENING

Fig. 9

Fig. 8

0

1

GRINDING

WHEEL

SPINDLE

SHAFT

STAR

WASHER(S)

HEX NUT(S)

SCREW(S)

WHEEL

NUT

OUTER

FLANGE

Fig. 10

page 9

INNER

FLANGE

WHEEL

GUARD COVER

LAWN MOWER

BLADE

SCREW DRIVER

Loading...

Loading...