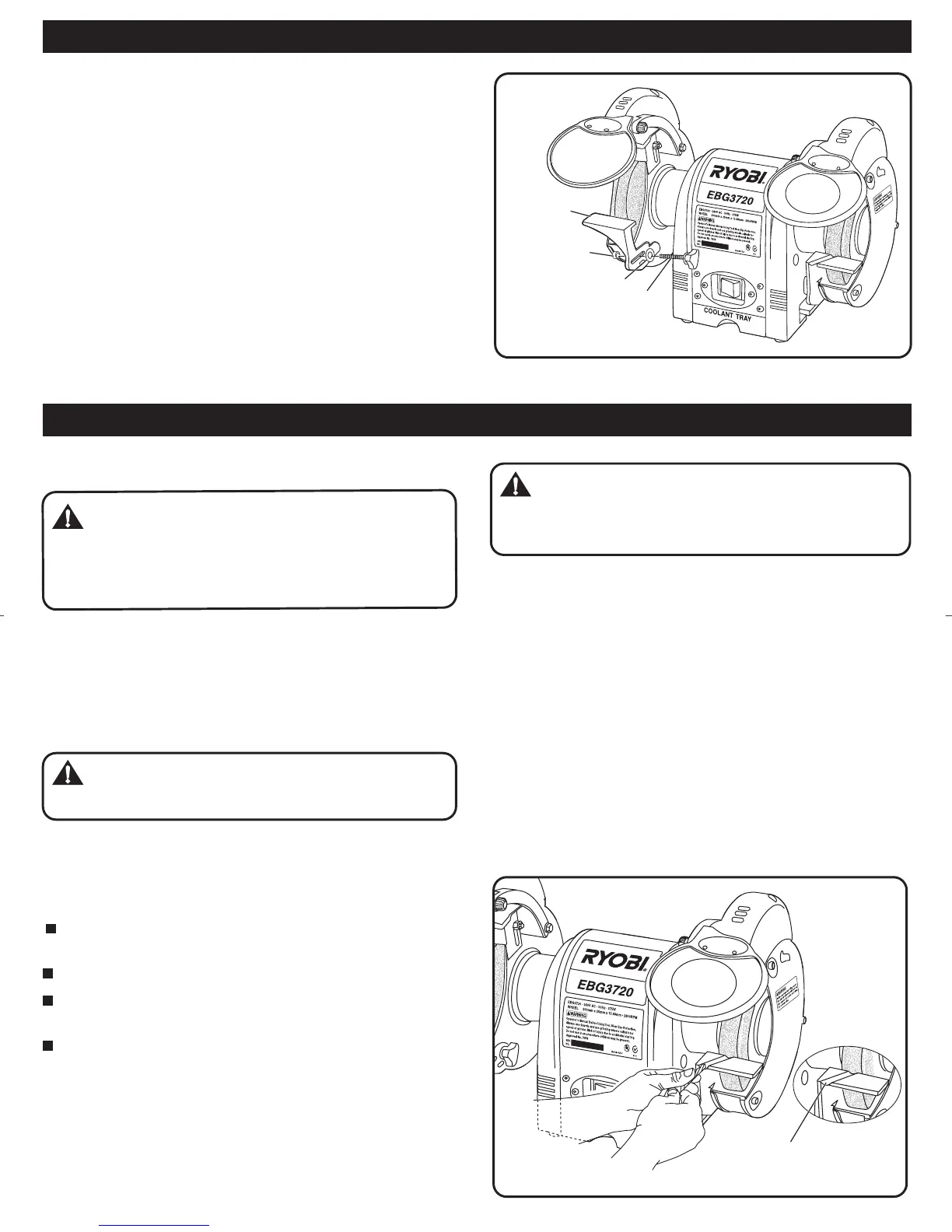

ASSEMBLY

OPERATION

WORK REST-EBG2515/EBG3720

See Figure. 6

Mount the work rests to the work rest bracket using the

knob, washer, and one hex nut.

Before tightening the bolts, adjust the gap between the

grinding wheel and the work rest to a maximum of 1.6mm.

Tighten securely.

Keep the object in constant motion, moving it at an

even pace.

BASIC OPERATION

To be efficient and work as designed, your tools should

be kept sharp. Dull tools can and will cause accidents.

Bench Grinders are ideal for sharpening tools such as

chisels, planer blades, scissors, etc., and for removing

rust or corrosion.

Grinders remove material rapidly so pressure is the key

to efficient grinding.

The proper way to sharpen a tool and avoid overheating is:

WARNING:

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing dust.

If operation is dusty, wear a dust mask.

WARNING:

Excessive pressure on a cold wheel may cause the wheel

to crack.

WARNING:

Never sharpen or grind anything made of aluminium.

Never force a tool against the grinding wheel.

Keep the tool cool by using either a cooling tray, or a

pan of water.

The grinding wheel should rotate "into" the object being

sharpened.

Fig. 6

The following recommendations will help you sharpen

specific tools:

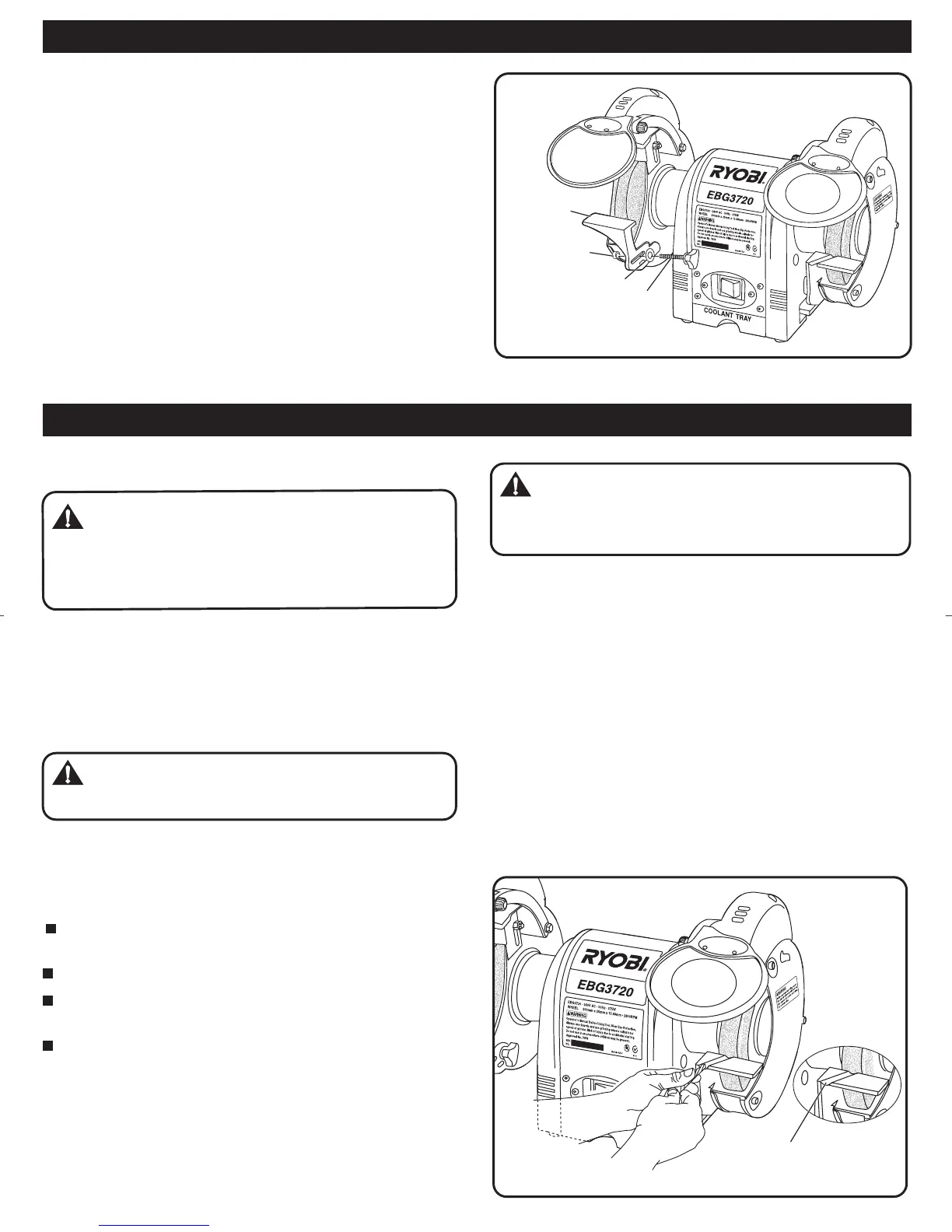

TWIST DRILL BITS

see Figure 7.

Drill bits are best sharpened on a sharpening jig ( available

at most hardware stores). Begin on one side of the point

at the existing angle, then twist the bit while maintaining

contact with the grinding surface. Sharpen only the tip.

Note: Excessive pressure may damage the tool, cause

the motor to overheat, and prematurely wear down the

grinding wheel.

0

1

HEX NUT

WORK REST

BRACKET

WASHER

KNOB

Page 8

This technique requires considerable practice, so take your

time and make a few " dry runs" first with the grinder off.

Be sure to maintain the original cutting edge angle as this

is important to the efficiency of your bits. One work rest

has a V-groove angled to fit most drill bits.

Fig. 7

BIT SHARPENING

V-GROOVE

Loading...

Loading...