www.scheppach.com / service@scheppach.com / +(49)-08223-4002-99 / +(49)-08223-4002-58

11 / 16

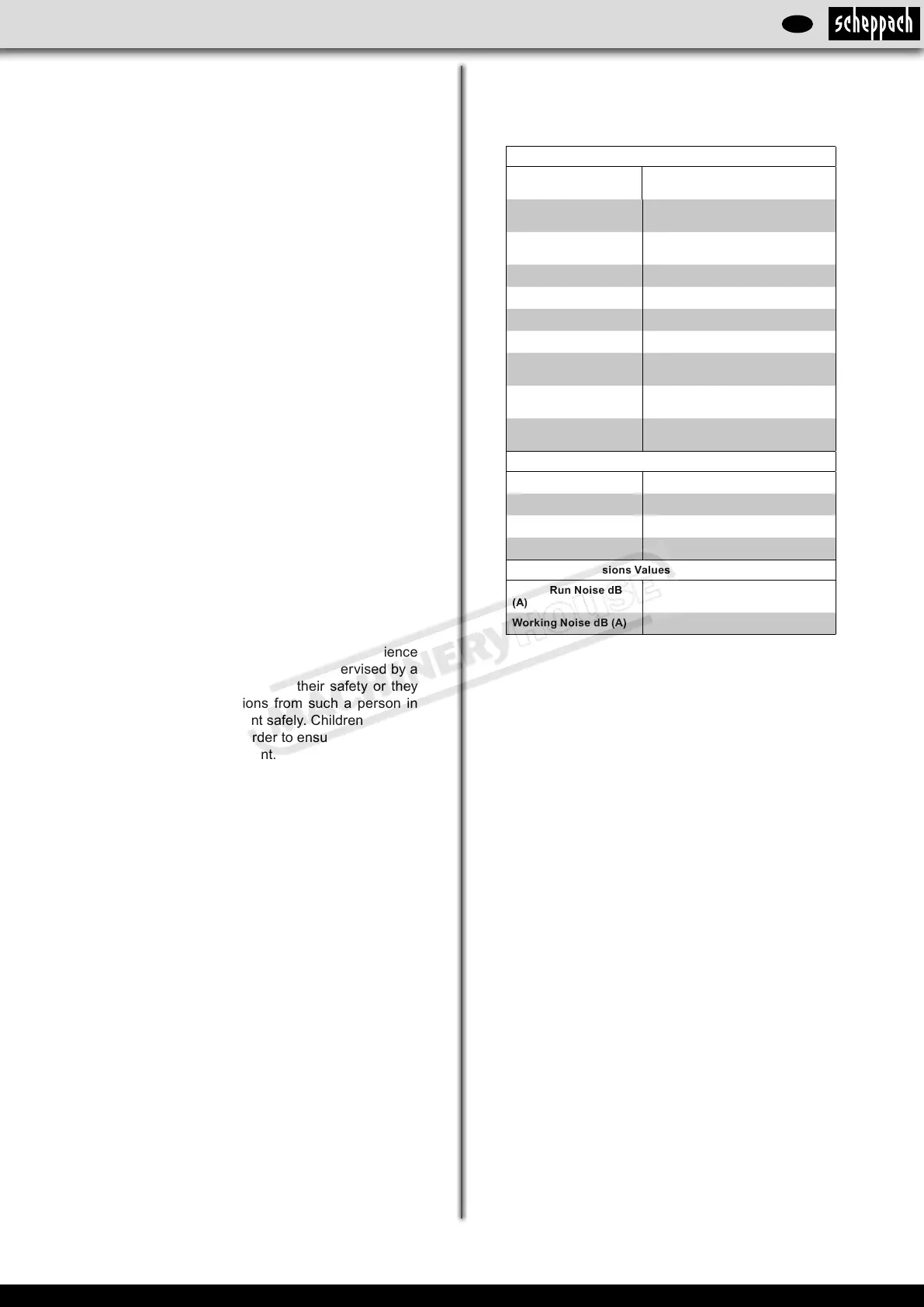

6. Technical data

Technical Data

Dimensions L x W x H

(mm):

830 x 520 x 1600

Overall height with

lter bag mm

1600

Ectractor duct

connections ø mm

100

Hose length mm

2300

Wheel diameter mm

150

Approx. weight kg

20

Rate of air ow m

3

/h

1150

Pressure differential

Pa

1600

Filter aera (lter bag)

m

2

approx. 1

Sawdust bag capacity

litres

75

Performance

Electric motor

230-240 V/5O Hz

Nominal input P1

0,55 kW

Output power P2

0,34 kW

Motorspeed 1/min.

2850

Work Place Emissions Values:

Empty Run Noise dB

(A)

75,5

Working Noise dB (A)

75,5

7. Assembly

For packaging reasons your machine is delivered in

semi-assembled state.

• Attach the side covering loosely to the base

frame using at-head screws M8 x 40 mm and

screw nuts. Do not tighten completely. Fig. 2, 3

• Attach the cross-member to the side covering

left and right with at-head screws M 8 x 12 and

screw nuts. Fig. 4, 5

• Remove 4 off the 6 screws (Motor end of the hous-

ing) on the blue metal plates bolted to each side

of the housing, As shown by the arrows in g.6

on page 4

• Attach the housing to the side coverings using the

4 Screws, washers and nuts previously removed.

• Securely tighten ALL base nuts and bolts now.

• Position the upper bag support bar into the hous-

ing and hang the cloth lter bag from it. Fig. 7

• Slide the longest bag clamp through the sleeve

on the bottom of cloth lter bag.

• Fix the top cloth lter bag on the container. Fig. 7

• Attach the plastic shavings bag to the lower air

ventilator using the shorter (1050mm) bag clamp.

Fig. 7

• Attach the exhaust hose to the nozzle on the

housing and afx it with a hose clamp. Fig. 8

• Attach the hose coupling to the other end of the

hose using a hose clamp. Fig. 9

• Do not use any low-powered machines for heavy

duty work.

• Do not mis-use the cable

• Make sure you stand squarely and keep your ba-

lance at all times.

• Check that the moving parts are in good working

order, that they do not jam, and that no parts are

damaged. Make sure that all parts are tted cor-

rectly and that all other operating conditions are

properly fullled.

• Unless otherwise stated in the operating instruc-

tions, damaged safety devices and parts have to

be repaired or replaced by an authorized service

center.

• Have damaged switches replaced by a customer

service workshop.

• This electric tool complies with the pertinent safety

regulations. Repairs are to be carried out only by

a qualied electrician using original replacement

parts or the user may suffer an accident.

• If necessary, wear suitable personal protection

equipment. This could consist of:

- Ear-muffs to prevent the risk of damaging your

hearing

- A breathing mask to prevent the risk of inhaling

hazardous dust

• The operator has to be informed about the condi-

tions with an inuence on noise development.

• Faults on the machine have to be reported to the

person in charge as soon as they are discovered.

• This appliance is not suitable for the collection of

dangerous dust.

• This equipment is not designed to be used by peop-

le (including children) with limited physical, sensory

or mental capacities or those with no experience

and/or knowledge unless they are supervised by a

person who is responsible for their safety or they

have received instructions from such a person in

how to use the equipment safely. Children must al-

ways be supervised in order to ensure that they do

not play with the equipment.

Remaining hazards

The machine has been built using modem techno-

logy in accordance with recognized safety rules.

Some remaining hazards, however, may still exist.

• Wood chips and sawdust can be health hazards.

Be sure to wear personal protective gear such as

safety goggles and a dust mask.

• Dust inhalation may occur when closing and replac-

ing the dust bag.

• Please note the instructions concerning proper dis-

posal in the operating manual (e.g. the use of P2

dust masks) to prevent dust inhalation.

• Noise can be a health hazard. The permitted noise

level is exceeded when working. Be sure to wear

personal protective gear such as ear protection.

• The use of incorrect or damaged mains cables can

lead to injuries caused by electricity.

• Even when all safety measures are taken, some re-

maining hazards which are not yet evident may still

be present.

• Remaining hazards can be minimized by following

the instructions in “Safety Precautions”, “Proper

Use“ and in the entire operating manual.

Keep this safety information in a safe place.

GB

Instructions Manual for HD12 (W886)

Loading...

Loading...