Connection

6.2 Electrical connection

1FT7 synchronous motors

Operating Instructions, 04/2010, 610.40075.40b

31

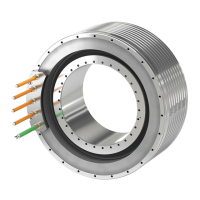

6.2.3 Motor connection

DANGER

Warning regarding motor damage!

The motor will be destroyed if it is directly connected to the three-phase line supply.

Only operate the motors with the appropriately engineered converters!

Ensure the correct phase sequence is used!

Encoder systems and temperature sensors are electrostatic sensitive devices (ESD). Do

not touch the connections with either hands or tools that could be electrostatically charged!

● We recommend that SIEMENS prefabricated cables are used (not included in the scope

of delivery). These cables reduce installation costs and increase operational reliability

(see the Configuration Manual).

● The manufacturer of the plant/machine is responsible for the ensuring that the installation

is performed correctly.

● Observe the data on the rating plate (type plate) and the circuit diagrams.

● Adapt the connecting cables in accordance with the type of use and the voltages and

currents that arise.

● When fed from a converter, high-frequency current and voltage oscillations in the motor

feeder cables can cause electromagnetic interference. Use shielded power cables and

signal lines. Carefully observe the EMC information of the converter manufacturer.

● Make sure that the inside of the connector is clean and free of cable cuttings and

moisture.

● Avoid protruding cable ends.

● Check seals and sealing surfaces of the connectors to ensure that the degree of

protection is maintained.

● Take measures to ensure that connecting cables cannot rotate, are not subject to strain

and pushing forces, and also provide anti-kink protection. It is not permissible to subject

the connector to continuous force.

● The coding groove of the plug-in connection must be inserted so that it is aligned in the

socket connector and the screw cap must be tightened by hand as far as it will go.

CAUTION

High thermal stress

For high thermal stresses, e.g. overload when the motor is stationary, the protective

function with integrated temperature sensor may not be adequate. In these cases, apply

additional protective measures, e.g. i²t monitoring.

Loading...

Loading...