Data transfer using CANopen Issue 01/05

CANopen Option Module Operating Instructions

56 6SE6400-5BC00-0BP0

3.3.1 CANopen control word

The CANopen control word is used in order to execute the state transitions

described in the previous Chapter.

Parameter P0700 (object:0x22BC*) must be set to 6 in order to transfer the

CANopen control word to the appropriate internal parameters.

The CANopen control word is then written into the inverter at P2050.00 (object

0x2802*) and is then internally copied into parameter r2090. The CANopen control

word is converted to the MICROMASTER control word in the option module. The

assignment of the bits of the CANopen control word to the MICROMASTER control

word are shown in the following table.

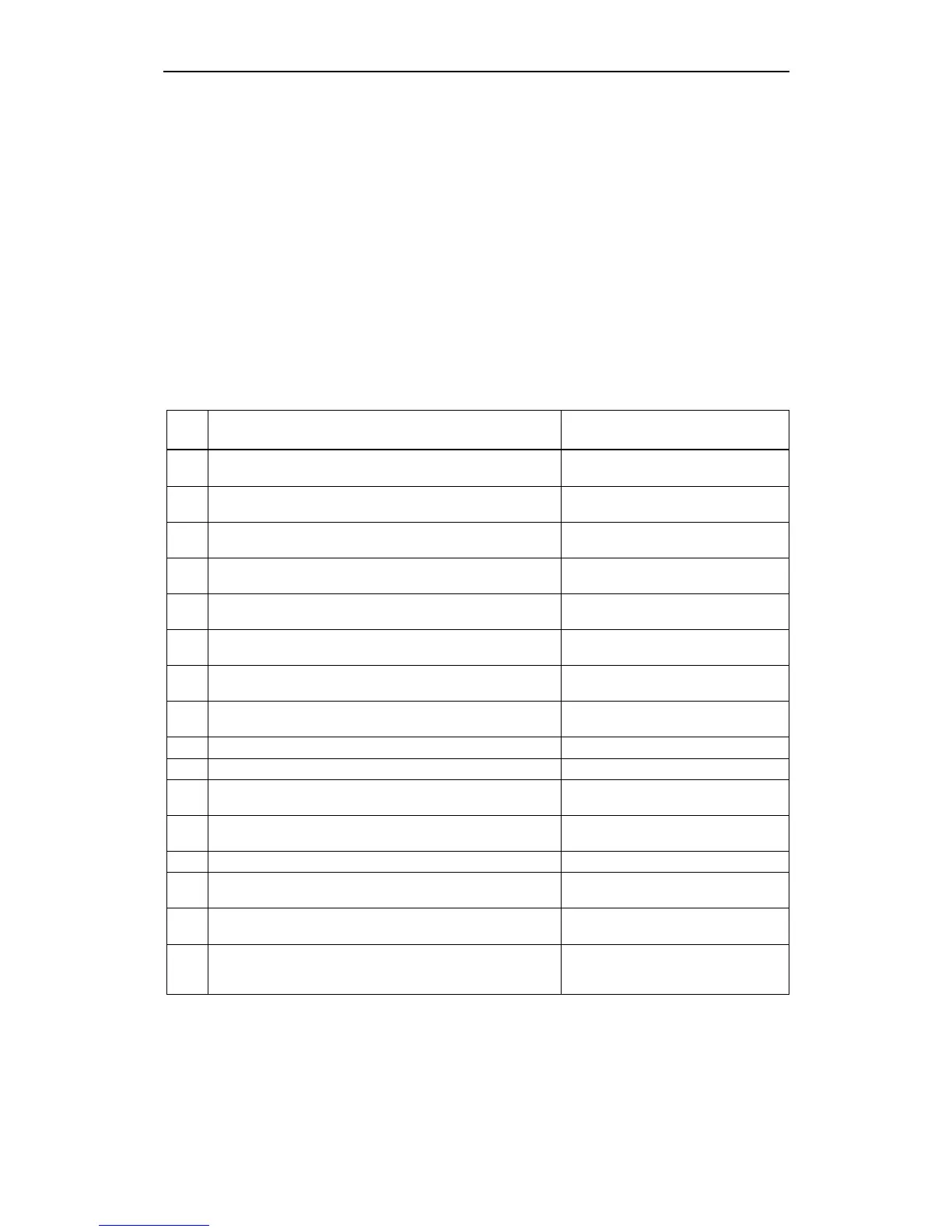

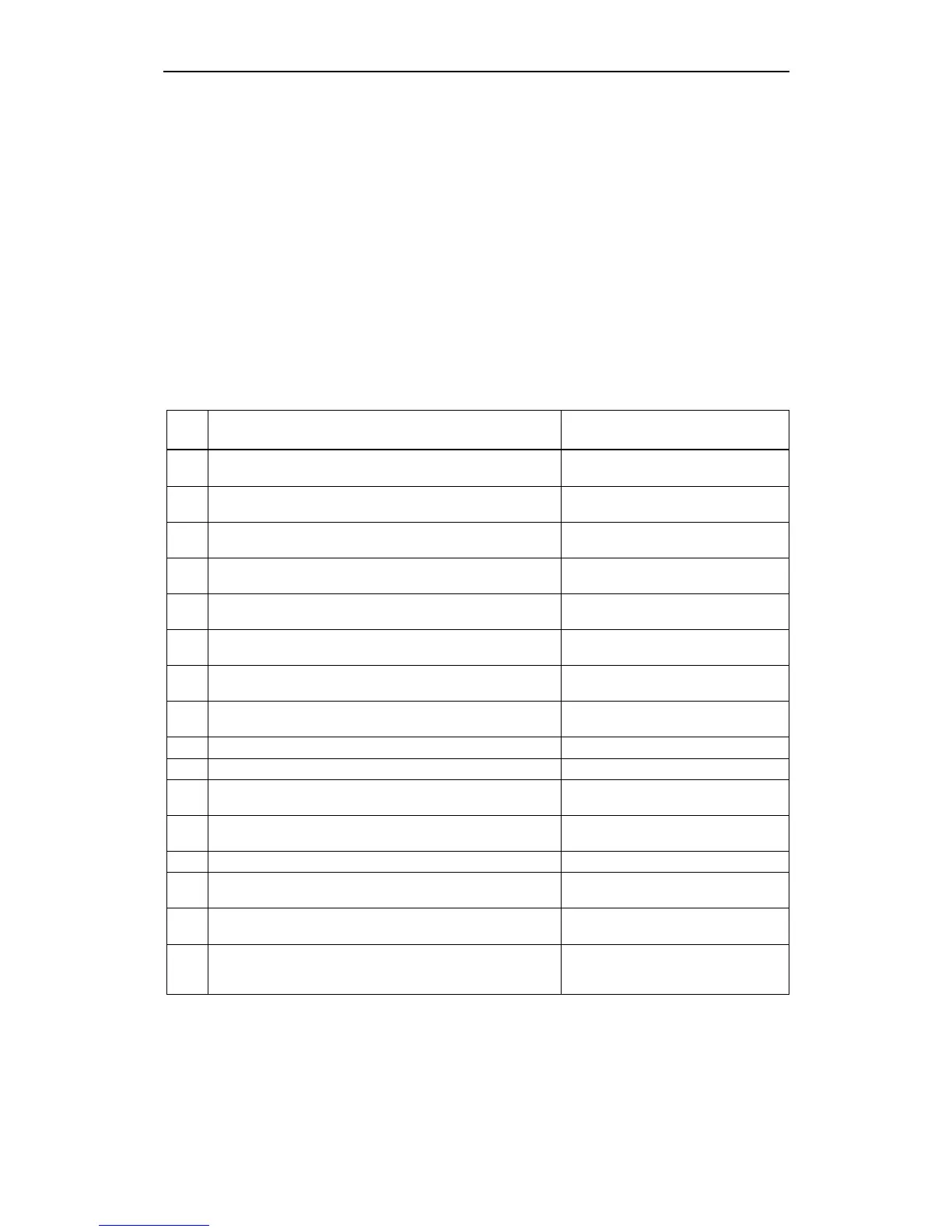

Table 3-15 Assignment of CANopen control word bits to MICROMASTER control word bits

Bit

Pos.

CANopen Control Word Drive Control Word

00 Switch ON 0 = NO

1 = switch ON

ON/OFF1 0 = OFF1

1 = RUN

01 Disable Voltage (OFF2) 1 = NO

0 = disable voltage

Do OFF2 0 = YES

1 = NO

02 Quick Stop (OFF3) 1 = NO

0 = quick stop

Do OFF3 0 = YES

1 = NO

03 Enable Operation 0 = NO

1 = enable operation

Pulse Enable 0 = NO

1 = YES

04 Operation Mode Specific:

RFG disable

0 = disable RFG

1 = enable RFG

RFG Enable 0 = NO

1 = YES

05 Operation Mode Specific

RFG Stop

0 = stop RFG

1 = start RFG

RFG Start 0 = NO

1 = YES

06 Operation Mode Specific

RFG Zero

0 = Zero RFG

1 = RFG not zeroed

Setpoint Enable 0 = NO

1 = YES

07 Reset Fault Fault Acknowledge 0 = NO

1 = YES

08 Halt Not used in CAN (forced to 0)

09 Reserved (0) No connection (forced to 0)

10 Reserved (always 1) Control from PLC (forced to 1) 0 = NO

1 = YES

11 Manufacturer Specific Reverse 0 = NO

1 = YES

12 Manufacturer Specific Not used

13 Manufacturer Specific Motor pot. UP 0 = NO

1 = YES

14 Manufacturer Specific Motor pot. DOWN 0 = NO

1 = YES

15 Manufacturer Specific CDS Bit 0 (Local / Remote)

(needs manually setting of

P0810.0 = 2090.15)

0 = NO

1 = YES

Loading...

Loading...