Functional safety for SIPART PS2 FF

32 A5E00489774-02, 10/2013

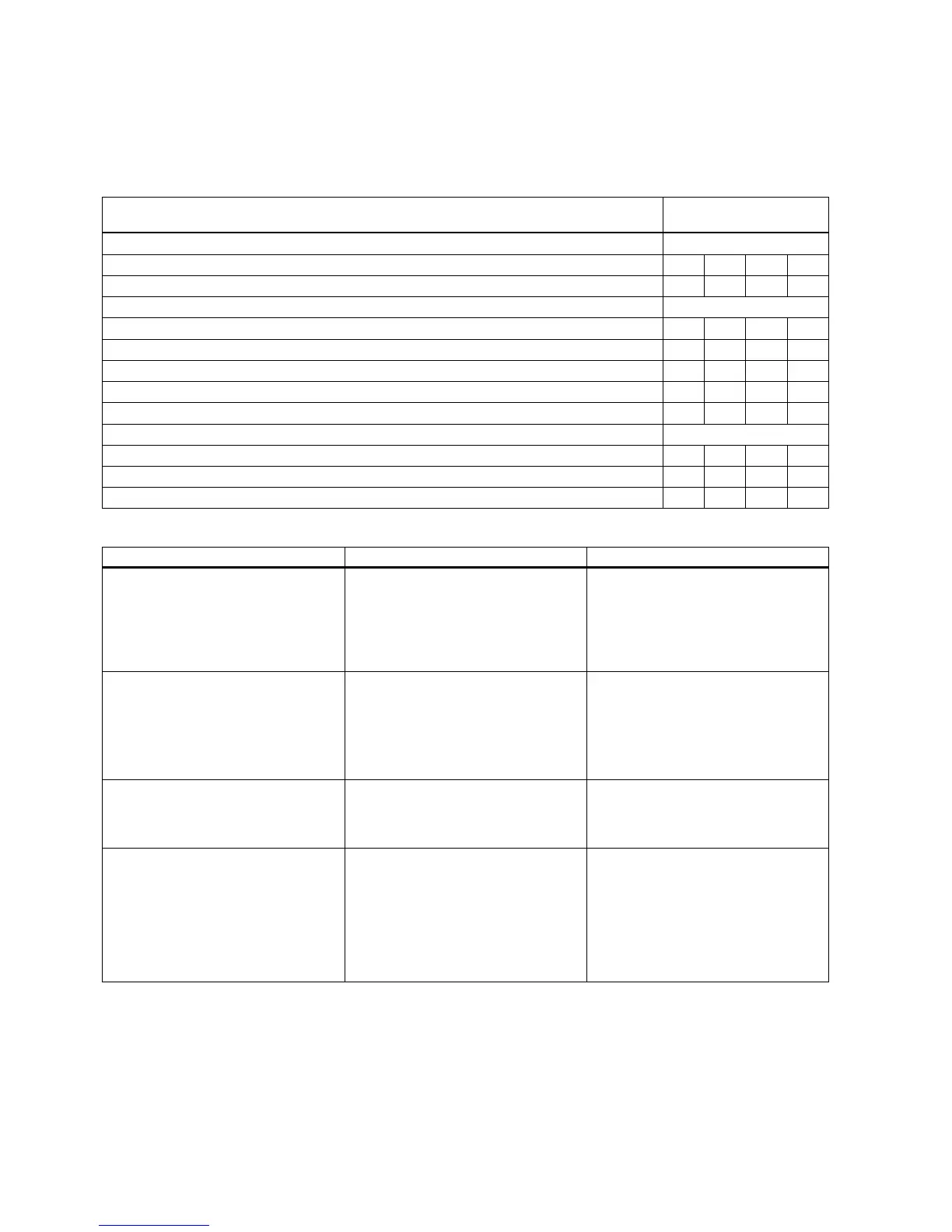

Fault identification

Diagnostics guide

Remedial measures, see

table

In which mode does a fault occur?

● Manual and automatic modes

In which environment and under which boundary conditions does a fault occur?

● Wet environment (e.g. strong rain or constant condensation)

Vibrating (oscillating) control valves

2 5

● Impact or shock loads (e.g. vapor shocks or breakaway valves)

Moist (wet) compressed air

● Dirty (contaminated with solid particles) compressed air

● Regularly (reproducible)

Sporadically (not reproducible)

● Mostly after a specific operation time

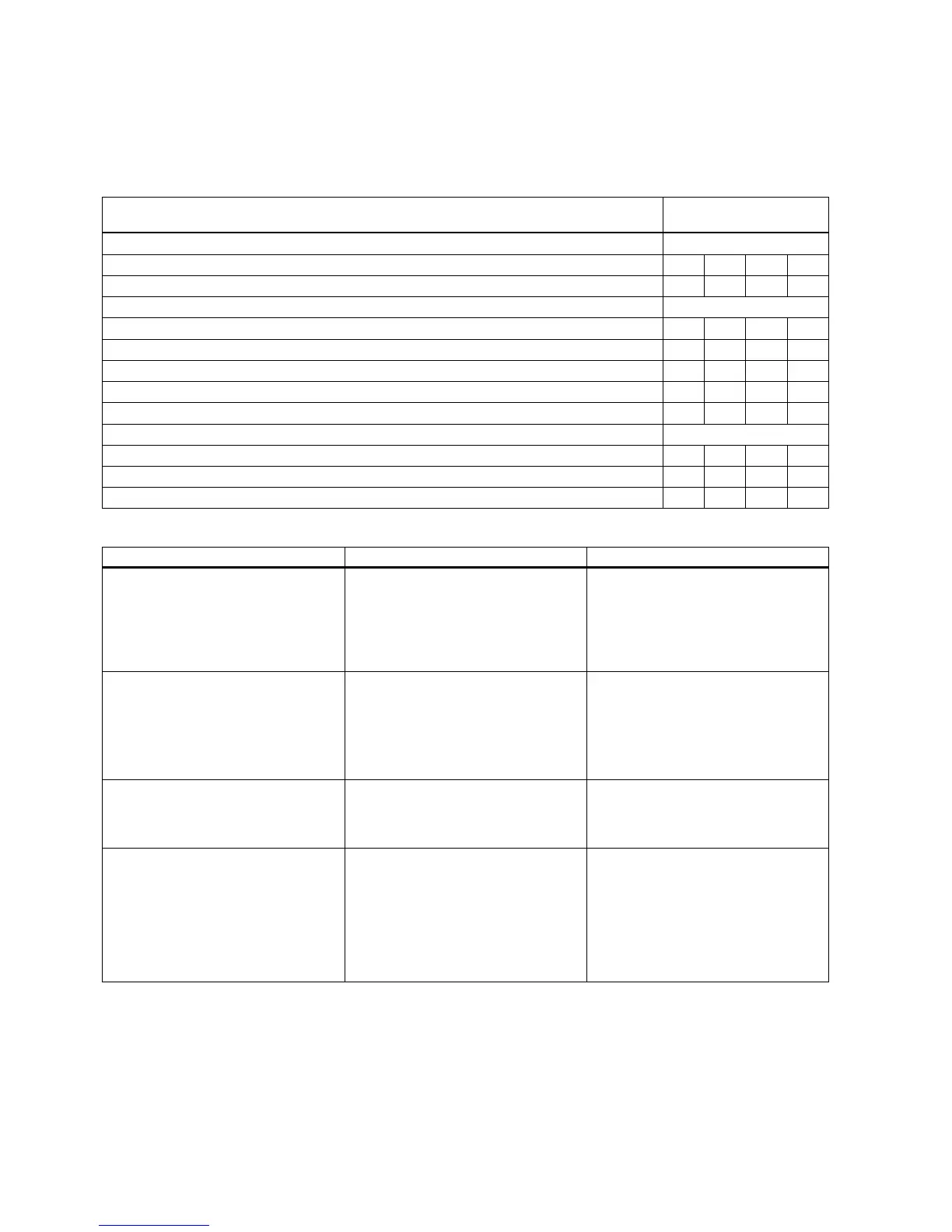

Remedial measures table 1

● Positioner remains in "RUN 1". ● Initialization started from the end

position and

●

The response time of a maximum of

1 minute was not observed.

● Network pressure not connected or

● A waiting time of up to 1 minute is

essential.

● Do not start initialization from the

end position.

● Provide the network pressure.

Positioner remains in "RUN 2".

Transmission ratio selector and

parameter 2

● "YAGL" and the real stroke do not

match.

● Incorrectly set stroke on the lever.

Piezo valve does not activate.

Check settings: see leaflet: "Device

view (7)" picture as well as

parameters 2 and 3

● Check the stroke setting on the

lever. See table 2

Positioner remains in "RUN 3".

Actuator actuating time is too high.

Open the restrictor completely

and/or set the pressure PZ (1) to

the highest permissible value.

Use a booster if required.

Positioner remains "RUN 5", does

not go up to "FINISH" (waiting time

> 5 min).

"Gap" (play) in the positioner -

actuator - control valve system

Part-turn actuator: check for the

firmness of the grub screw of the

coupling wheel

● Linear actuator: check for the

firmness of the lever on the

positioning shaft.

● Remove any play between the

actuator and the control valve.

Loading...

Loading...