FLEXIBLE ASSEMBLY SYSTEM FAS200

User Manual for FAS200 - 14 -

Different layouts can be defined for future expansions. The transfer follows a

rectangular path or linear path. The master PLC controls and coordinates the

rest of the PLCs connected to the network and it is located in the “body feeding

and checking” station (FAS201 module).

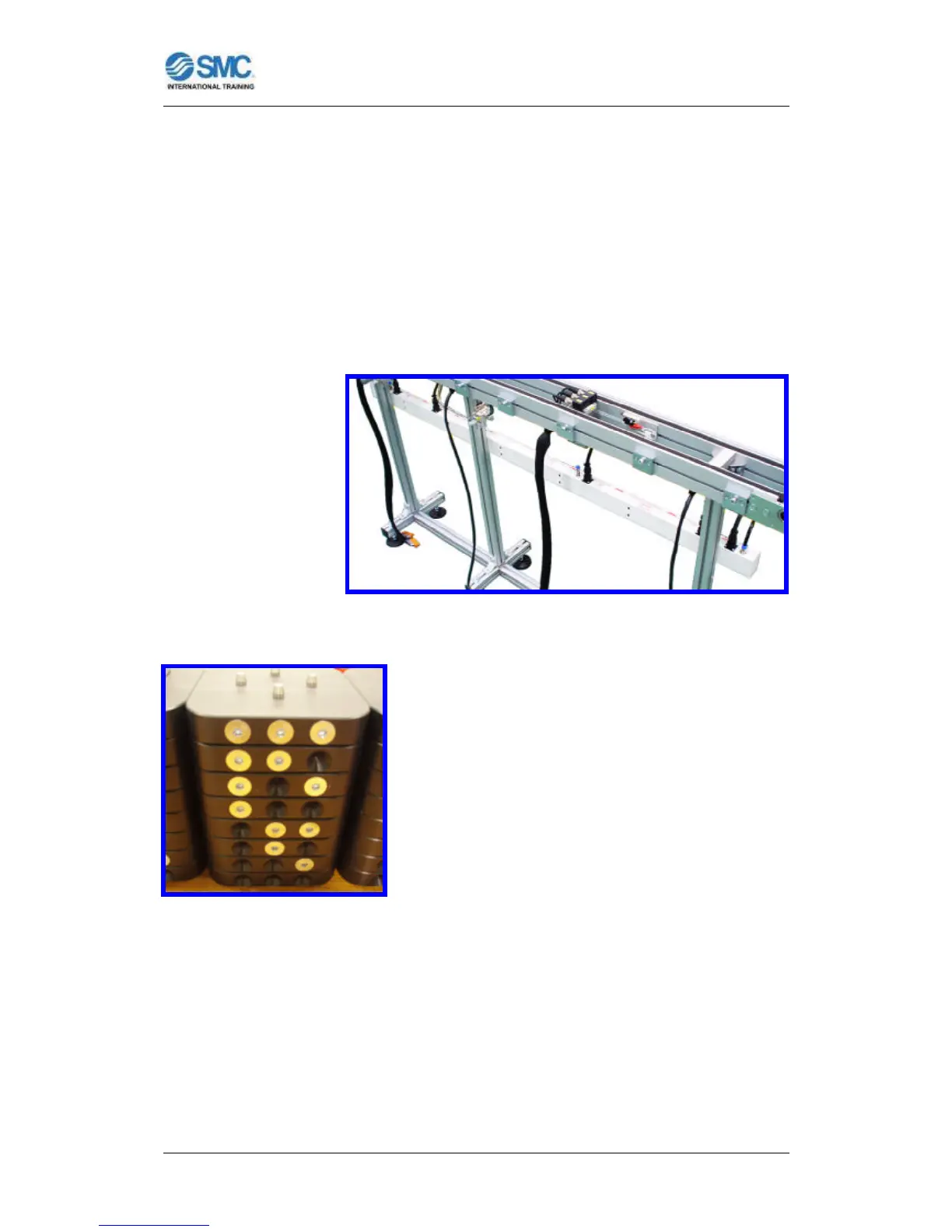

There is a longitudinal channel in one side of each module and of the linear

transfer to provide the electrical power connections and the air supply

connections between

the different stations

(and in some

configurations the

communication

connections).

Figure 15: Longitudinal channel for connections.

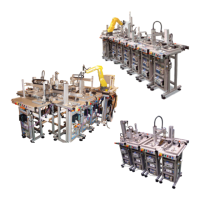

The modular transfer incorporates a pallet

assembly to transport parts and assemblies

across the handling stations. The pallets and the

transfer stoppers incorporate a binary coding

system using inductive detectors, which allow the

Control System to identify the position of each

pallet at any time.

Figure 16: Binary code on

the pallets.

In front of some modules (which need to interact with the linear transfer

system), there is a mechanical end to stop the pallets, and, depending on the

particular process, a further series of elements for lifting, centering, turning, etc.

All these transport system actuators, stoppers, lifters, positioners and

Loading...

Loading...