-33-

No.PF※※-OMO0012-D

Troubleshooting

Troubleshooting

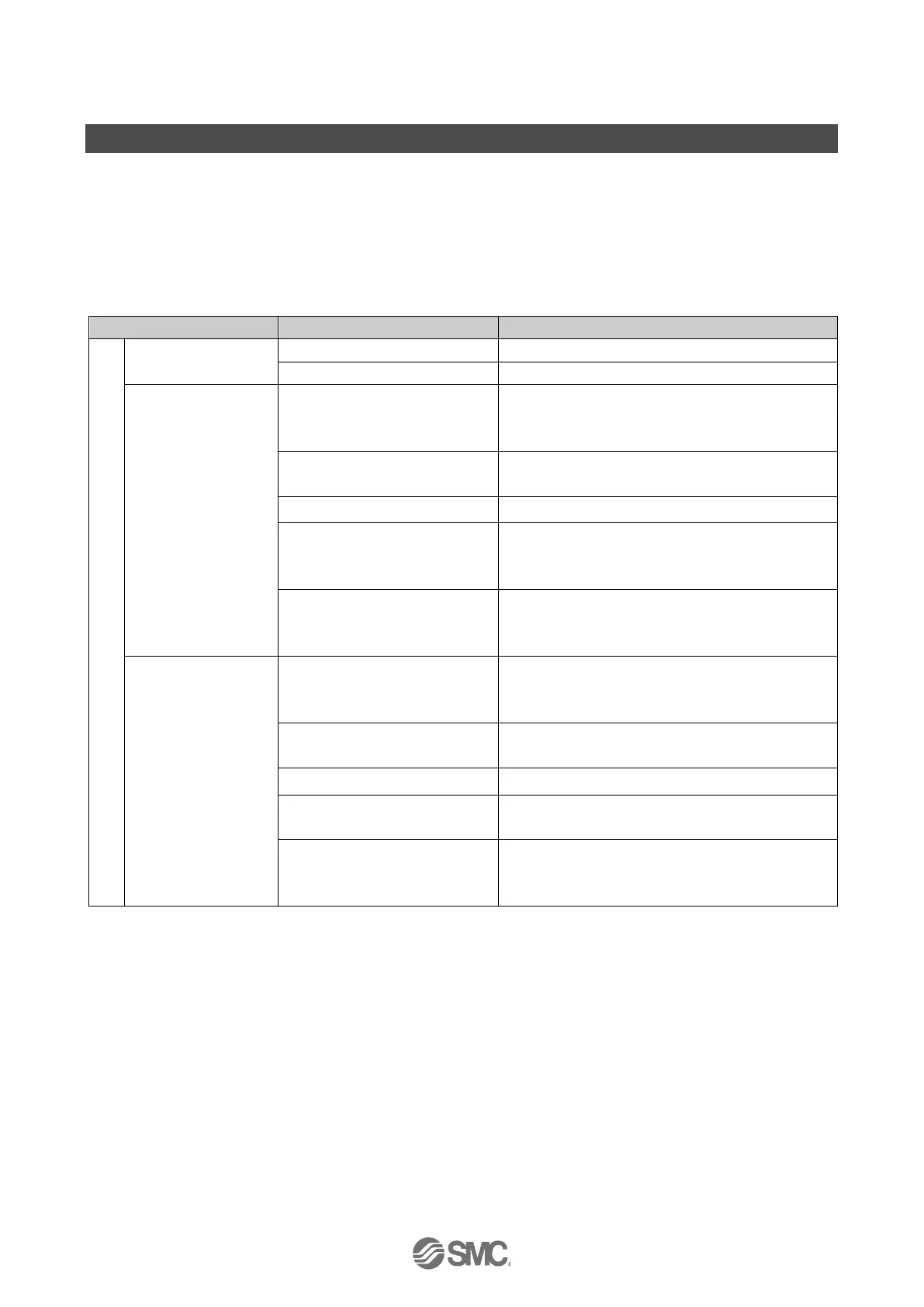

If an operation failure occurs with the product, use the table below to find out the cause of the problem.

If none of the countermeasures seem to be applicable, or a replacement product operates normally when

installed, the product may be faulty. A product can be damaged by the operating environment (system

configuration etc). If the product seems to be faulty, please contact SMC.

■Cross-reference for troubleshooting

Set up filter (approx.40 mesh) at IN side of product.

If there is foreign matter stuck to the mesh, remove it

completely, taking care not to damage the product.

Piping is connected in the wrong

direction.

Install with the mounting direction corresponding to

the flow direction (arrow indicated on the product).

Insufficient fluid supply.

Change to a pump that has less pulsation. Install a

tank to reduce the pressure fluctuation. Change the

piping to elastic piping such as rubber tube.

Check that seal tape has been applied correctly.

Reconnect the pipes with the specified tightening

torque.

The display is not

correct.

Set up filter (approx.40 mesh) at IN side of product.

If there is foreign matter stuck to the mesh, remove it

completely, taking care not to damage the product.

Piping is connected in the wrong

direction.

Install with the mounting direction corresponding to

the flow direction (arrow indicated on the product).

Insufficient fluid supply.

An incorrect flow unit was

selected.

Select the appropriate flow unit.

Check that seal tape has been applied correctly.

Reconnect the pipes with the specified tightening

torque.

: Operate only the product with unit selection function

Loading...

Loading...