Maintenance Manual STEMME S10

Date of Issue: Oct. 1, 1990 page: 25

Amendment No.: 18 Date: Oct. 15, 2012

A4010021_B19.doc

Doc.No.: A40-10-021

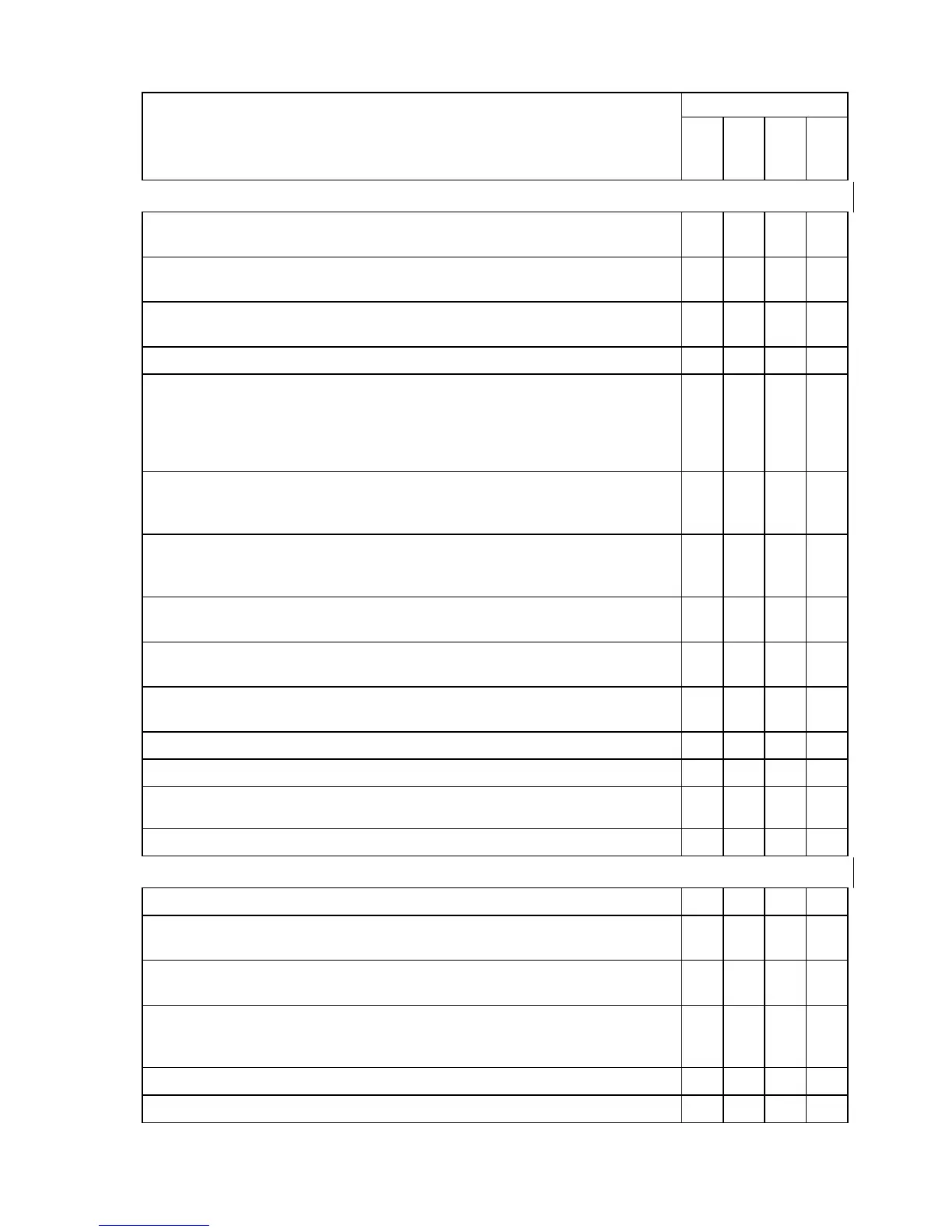

Inspection Type

Type and Subject of Inspection

Type 1a

Type 2

Type 3

5.3.3 Cockpit

1.

Inspect the canopy for damage and proper functioning of the locking

mechanism. Grease in case of stiff operation.

X X X

2.

Emergency jettisoning system: functional check. The compressed gas spring

must have a minimum strength of 150 N.

X

3.

Check lateral gas springs for proper function: canopy must remain in the

opened position.

X

4.

Inspect safety harnesses and their points of attachment. X

5.

Check stops, smooth movement and neutral position of the control sticks.

Check all controls for ease of operation, including flap, air brake and trim

controls. If there is any jamming or chafing within the range of operation, trace

and eliminate the reason. Counterforce at the flap lever in "L"-position must be

28 ± 6 lbf (125 ± 25 N), damping must be perceivable in both directions.

X X X

6.

Remove control system coverings to the left and to the right, check for foreign

objects. Check bearings for proper condition and all joints for tight fit. Inspect

rods and bellcrank levers for cracks, deformation an other defects.

X X

7.

Examine all control rods in the terminal swaging area for embrittlement or

crack initiation (axial and peripherical direction), check fork terminals for

cracks, particulary the fork terminals where the root turns into the webs.

X X

8.

Inspect condition and attachment of instruments, switches, circuit breakers,

fuses and wiring.

X X X X

9.

Flexible hoses of ventilation, heating and instruments: Check condition and

installation.

X X

10.

Inspect and if necessary replace moisture/dust filters in the instrument hose

system.

X

11.

Inspect rudder pedals and cables, check adjustment device. X X X

12.

Seats: check condition, attachment and adjustment device. X X X

13.

If installed in the cockpit: check condition of battery(ies), their terminals, and

installation

X

14.

Functional check of propeller brake and propeller positioning X X X

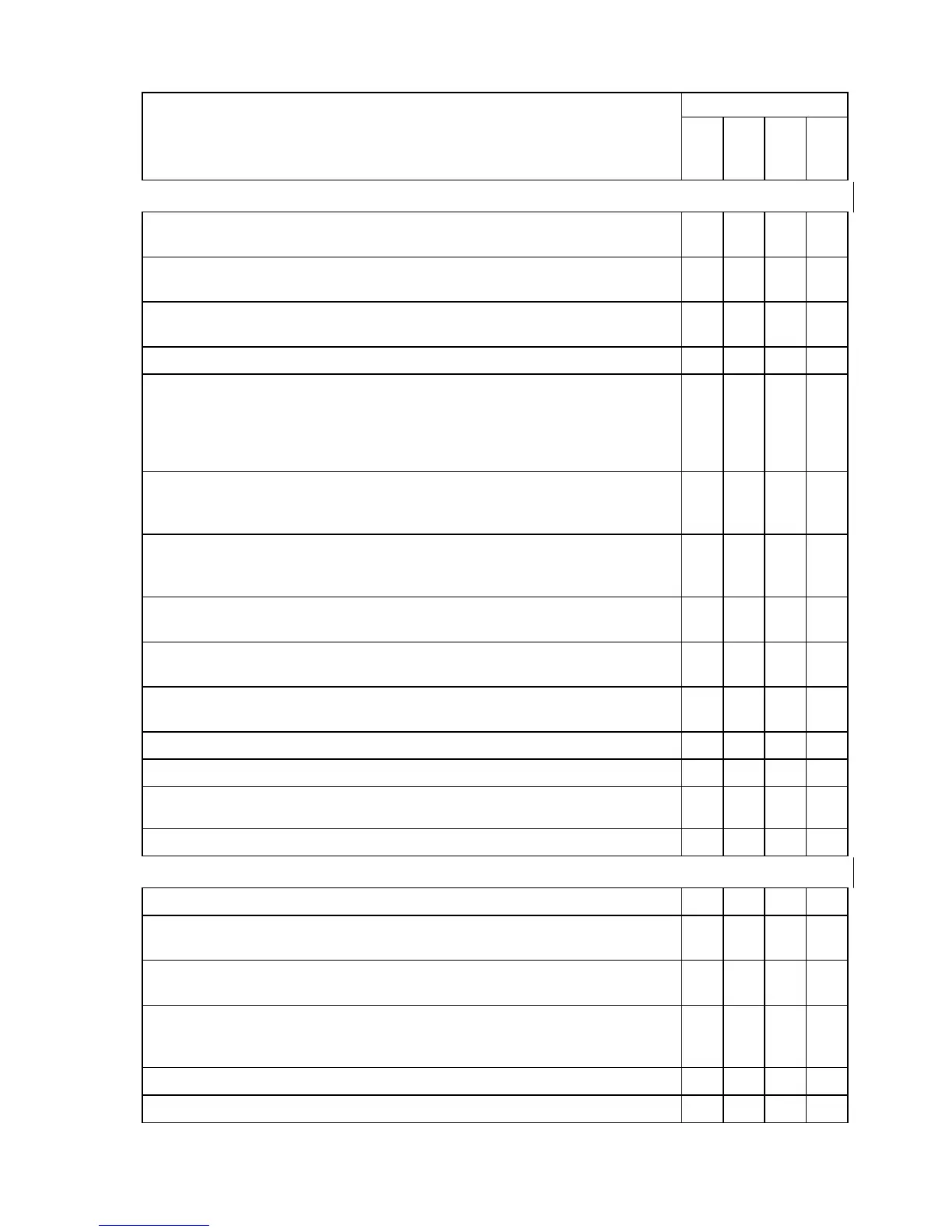

5.3.4 Centre Section of Fuselage

1.

Inspect central fuselage framework for damage, corrosion, and chafe marks. X

2.

Check condition of framework/ tailboom attachment points and tight fit of screw

Check condition of lower attachment points framework to front fuselage section

and tight fit of screw joints.

X

4.

Inspect all control rods and levers in the central fuselage for tight fit of all joints,

proper condition of the bearings, and for defects such as cracks or

deformation. Check rudder cable guides for proper condition and tight fit.

X X X

5.

Check flap relief gas spring for proper condition and tight fit at the hinge points.

Check condition, fit and locks of cowlings and coverings. X X X

Loading...

Loading...