Maintenance Manual STEMME S10

Date of Issue: Oct. 01, 1990 page: 28

Amendment No.: 18 Date: Oct 15, 2012

A4010021_B19.doc

Doc.No.: A40-10-021

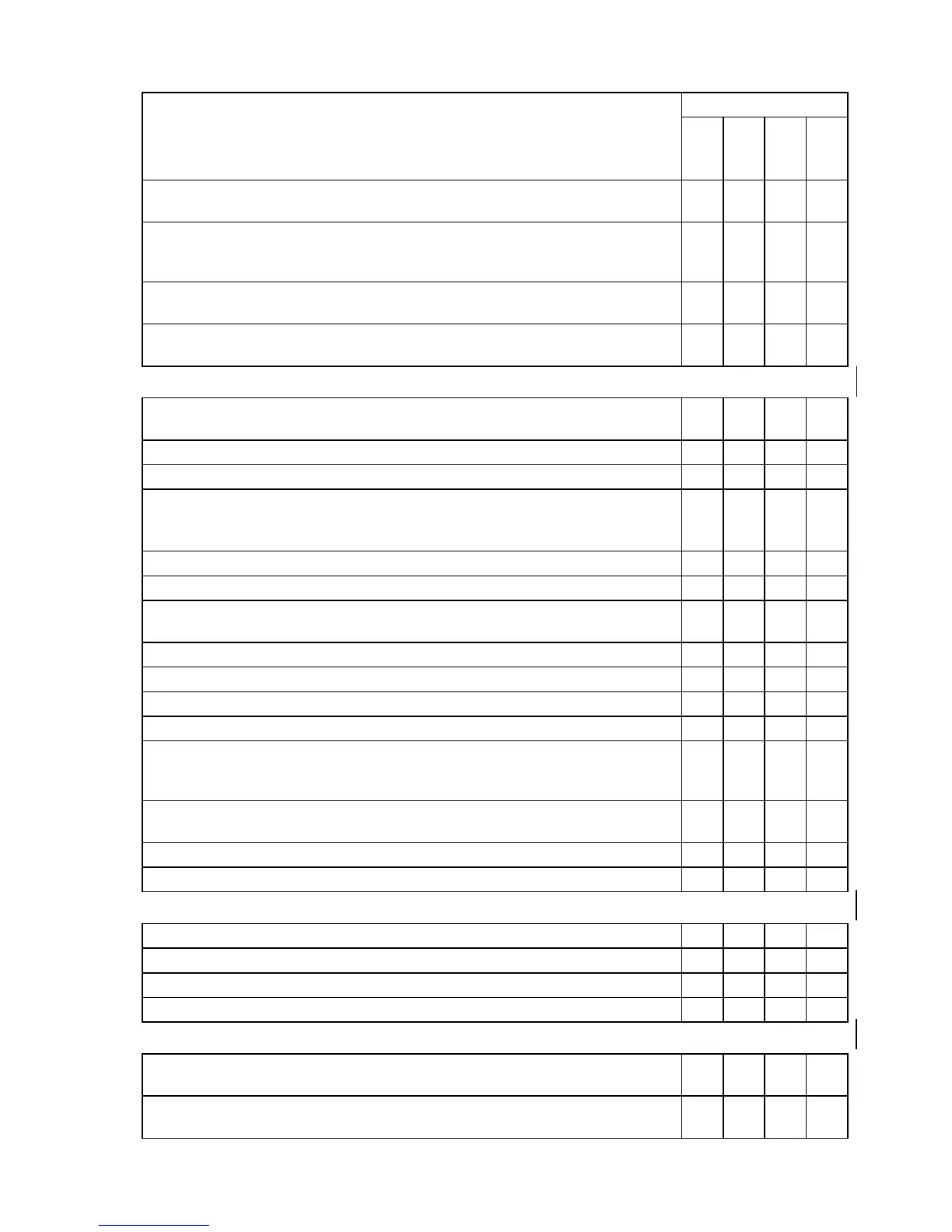

Inspection Type

Type and Subject of Inspection

Type 1a

Propeller brake: check thickness of brake band lining - min. .06 in./1.5

Check actuation mechanism for smooth operation.

X X

6.

Check condition and tension of V-belts: Press-in depth 3.7 mm at a press-

down force of 50 N on each belt, applied half-

way between the axes. Adjust if

necessary, then fit new safety lock wire.

X X X X

7.

and securing of the gearbox suspension at the front spar, and

for proper condition - rubber material must be free of embrittlement or cracks.

X X X

8.

Check transmission gear bearings for running noise and lubricant leakage (t

the propeller by hand).

X X X

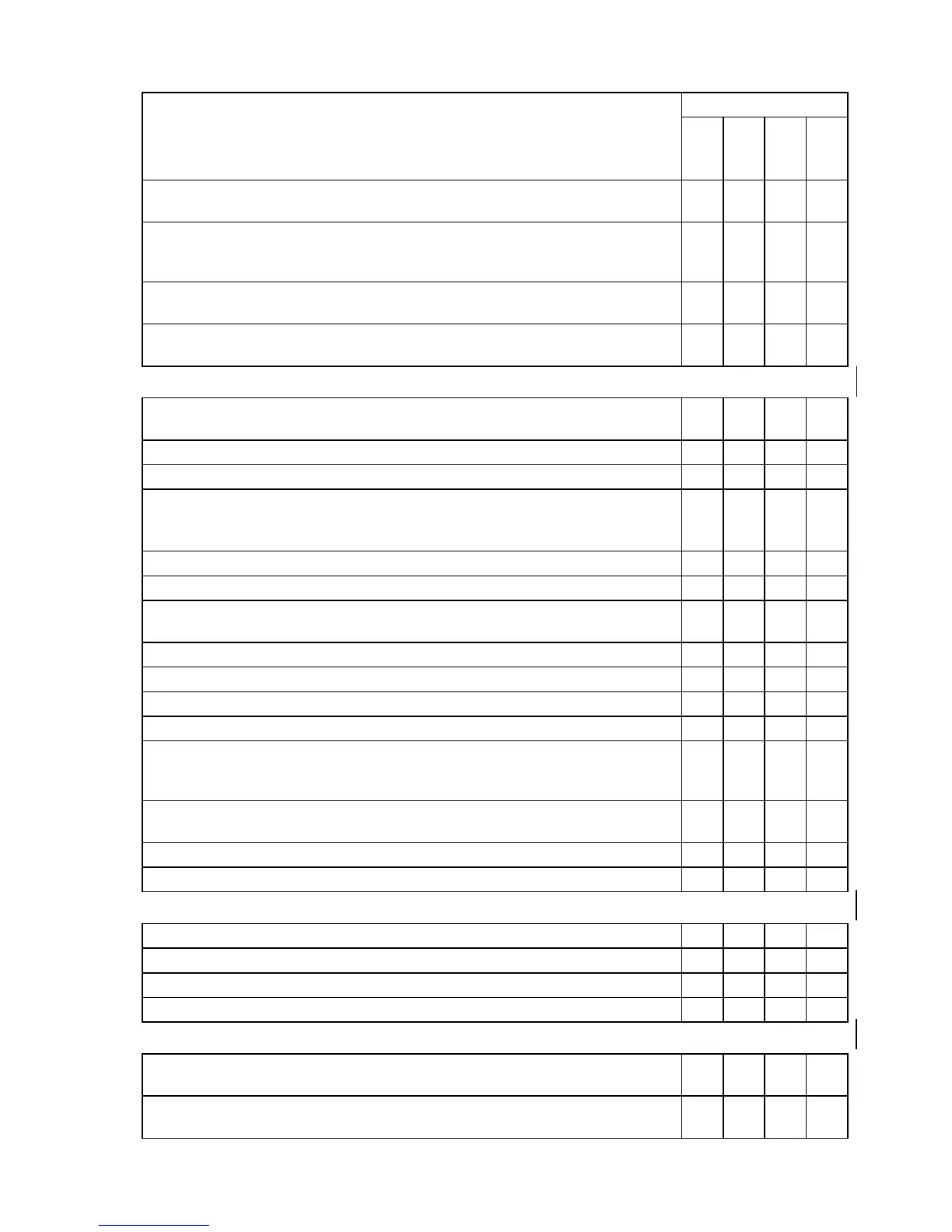

5.3.10 Main Landing Gear

1.

Inspect the main landing gear legs and trailing arms for deformations and

possible cracks as an result of overloads

X X X X

2.

Check the linear actuators for external damages X X X

3.

Inspect the screw joint of the complete landing gear X X X

4.

Check condition of main landing gear tires, creep markings. Tire pressure:

[45 - 48 p.s.i. (3.1 - 3.3 bar)]

5s

[36 – 39 p.s.i. (2.5 - 2.7

tires installed]

5

a

X X X X

5.

Functional check of trailing arm link suspension. X X

6.

Wheel bearings: check for ease of operation and slackness. X X X

7.

Inspect brake master and wheel cylinders. Check brake hoses and pipes for

proper guidance, chafe marks and leakage.

X X X

8.

Inspect brake discs and brake linings (min. .06 in./1.5 mm). X X

9.

Check brake fluid level (replace fluid once in two years). X X X

10.

Check efficiency of brakes. X X X X

11.

Clean and regrease hinges of landing gear doors. X X

12.

Check function of landing gear (support aircra

ft on trestles): limit switches, fit of

gear doors, bowden cables for emergency release and the release mechanism

on the brace strut, for improper operation and poor condition.

X X X

13.

Inspect the operating mechanism of the LH landing gear door, including

bowden cable, for improper operation and poor condition.

X X X

14.

Check landing gear position indicator and warning system X X X X

15.

Functional check of landing gear Emergency Let Down X

5.3.11 Tail Wheel

1.

Check tail wheel unit for ease of operation and slackness. X X

2.

Check condition of tire, check pressure (2.8 ± 0.2 bar) and creep marking.

X X X X

3.

Inspect wheel fork, including journal bearing. X X X

4.

Check spring coupling between tail wheel and rudder X X X

5.3.12 Flight Instruments and Static Pressure System

1.

Check condition and function - if applicable service life limits -

control instruments (see Equipment List)

X

2.

Check adjustment of the stall warning system (every second

Loading...

Loading...