62

ENGLISH

EN

4.7 Stop

Disengage the power take-off. Apply the parking

brake.

Allow the engine to idle 1-2 mins. Stop the engine

by turning off the ignition key.

Shut off the petrol cock. This is particularly impor-

tant if the machine is to be transported on a trailer

for example.

If the machine is left unattended, re-

move the spark plug cable(s) and re-

move the ignition key.

The engine may be very warm immedi-

ately after it is shut off. Do not touch the

silencer, cylinder or cooling fins. This

can cause burn injuries.

4.8 Cleaning

To reduce the risk of fire, keep the en-

gine, silencer, battery and fuel tank free

from grass, leaves and oil.

To reduce the risk of fire, regularly

check the machine for oil and/or fuel

leakage.

Clean the machine after each use. The following

instructions apply for cleaning:

• When washing the machine with water under

high pressure, do not point the jet directly at

axle seals, electrical components or hydraulic

valves.

• Do not spray water directly at the engine.

• Clean the engine with a brush and/or com-

pressed air.

• Clean the engine’s cooling air intake (10, 11,

12:W).

5 MAINTENANCE

5.1 Service programme

In order to keep the machine in good condition as

regards reliability and operational safety as well as

from an environmental perspective, STIGA’s Ser-

vice programme should be followed.

The contents of this programme can be found in

the attached service log.

Basic service

must always be carried out by an au-

thorised workshop.

First service and intermediate service

should be

carried out by an authorised workshop, but can

also be carried out by the user. The content of this

can be found in the service log and the actions are

described under “4 STARTING AND OPERA-

TION” as well as below.

Servicing carried out at an authorised workshop

guarantees professional work using genuine spare

parts.

At each basic service and intermediate service car-

ried out at an authorised workshop, the service log

is stamped. A service log presenting these services

is a valuable document that improves the ma-

chine’s second-hand value.

5.2 Preparation

All service and all maintenance must be carried out

on a stationary machine with the engine switched

off.

Prevent the machine from rolling by al-

ways applying the parking brake.

Stop the engine.

Prevent unintentional starting of the

engine by disconnecting the spark plug

cable(s) from the spark plug(s) and re-

moving the ignition key.

5.3 Tyre pressure

Adjust the air pressure in the tyres as follows:

Front: 0.6 bar (9 psi).

Rear: 0.4 bar (6 psi).

5.4 Changing engine oil

This section contains tables covering the different

engines that are included in STIGA’s range. To fa-

cilitate reading, mark the data that applies to the

relevant machine/engine.

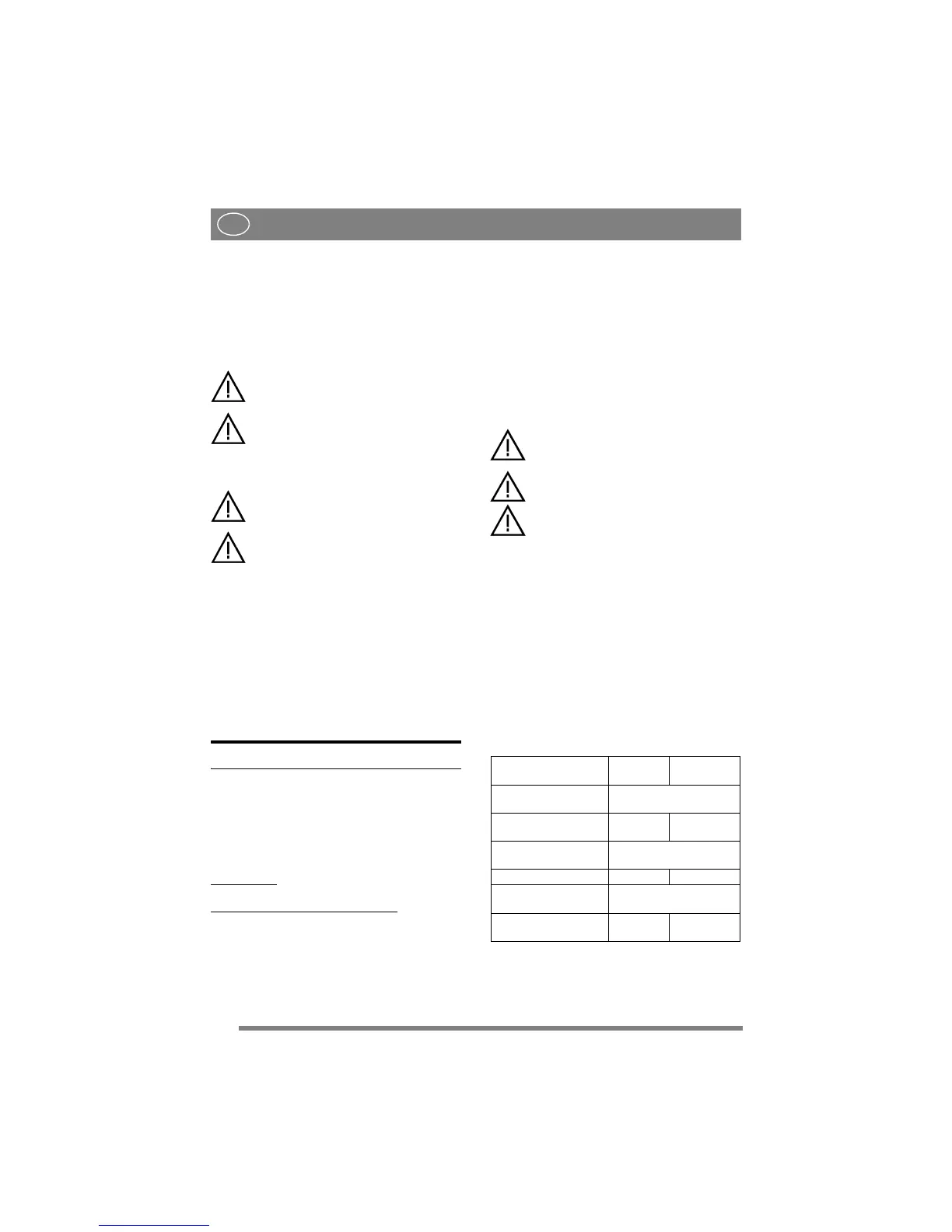

5.4.1 Change intervals

The table below states hours of operation and cal-

endar months. Carry out the relevant action at

whichever occurs first.

Change the oil more frequently if the engine has to

operate in demanding conditions or if the ambient

temperature is high.

Machine

1st time Then at

intervals of

Comfort (B&S) Hours of operation/Cal-

endar months

Changing the oil

5 hours

50 hours/

12 months

Prestige (Kohler) Hours of operation/Cal-

endar months

Changing the oil - 100 hours

Royal (Honda) Hours of operation/Cal-

endar months

Changing the oil 20 hours/

1 month

100 hours/

6 months

Loading...

Loading...